Field Control Method of DC Shunt Motor:

The Field Control Method of DC Shunt Motor are in general much more adaptable speed drives than ac motors which are associated with a constant-speed rotating field. Indeed one of the primary reasons for the strong competitive position of dc motors in modern industrial drives is the wide range of speeds afforded.

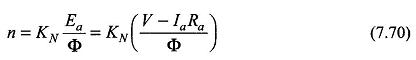

From Eq. (7.48)

Since the armature drop is small, it can be neglected.

This equation gives us two methods of effecting speed changes, i.e. the variation of field excitation, If and that of terminal voltage, V. The first method causes a change in the flux per pole, Φ and is known as the field control and the second method is known as the armature control.

Field Control Method of DC Shunt Motor:

For fixed terminal voltage, from Eq. (7.71)

which for linear magnetization implies

Disadvantages of Field Control Method:

- Speeds lower than the rated speed cannot be obtained because the field cannot be made any stronger; it can only be weakened.

- Since the speed is inversely proportional to the flux/pole while the torque is directly proportional to it for a given armature current, it can cope with constant kW drives only where the load torque falls with speed.

- For motors requiring a wide range of Field Control Method of DC Shunt Motor, the field ampere-turns are much smaller than the armature ampere-turns at high speeds causing extreme distortion of the flux density in the air-gap. This leads to unstable operating conditions or poor commutation. Compensating winding can be used to increase the speed range which can be 2 to 1 for large motors, 4 to 1 for medium sized ones and 8 to 1 for small motors. Even then the field control is restricted to small motors.

- This control method is not suited to applications needing speed reversal; since the only way to reverse speed is to disconnect the motor from the source and reverse the field/armature polarity. The field circuit being highly inductive, it is normally the armature which is reversed.

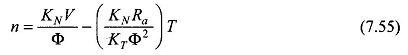

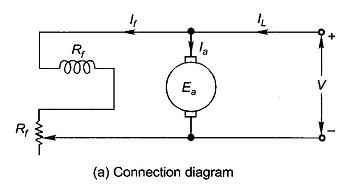

Figure 7.53(a) illustrates the field control for shunt motors; the control being achieved by means of a rheostat in the field circuit. Reproducing Eq. (7.55) here for convenience:

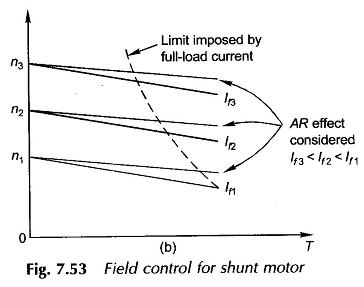

The speed-torque characteristic which has a small linear drop due to the second term (Ra effect) and translates upwards as the field is weakened due to the armature reaction is shown in Fig. 7.53(b). The demagnetizing effect of the armature reaction causes the characteristics to somewhat bend upwards with increasing torque (increasing load current). The working range of the speed-torque characteristic reduces with increasing speed in order for the armature current not to exceed the full-load value with a weakening field.