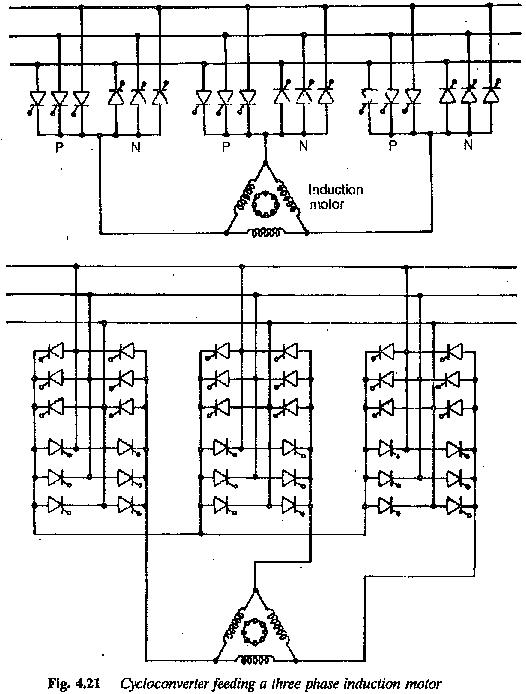

Cycloconverter Feeding Three Phase Induction Motor Drive:

Variable frequency supply to an induction motor may be obtained by using a cycloconverter. As has already been discussed, a cycloconverter is a single stage frequency conversion device which converts ac line frequency to a variable frequency. A Cycloconverter Feeding Three Phase Induction Motor Drive is shown in Fig. 4.21. A cycloconverter fed induction motor drive has the following features:

1.The voltage control is possible in the converter itself, so that the machine operates at its rated flux conditions.

2.The cycloconverter operates by means of line commutation. No forced commutation is required as the necessary reactive power for commutation is provided by the line. Losses due to forced commutation can be eliminated. The converter operates at lagging powerfactor. The line power factor is very poor at light loads.

3.The firing angles of the thyristors are modulated so that a mean sinewave voltage is synthesised from the input voltage waveform. Thus, a cycloconverter delivers a high quality sinusoidal waveform at all frequencies. When this voltage is impressed across the machine terminals a current which is almost sinusoidal will flow, as the machine inductance causes harmonic attenuation. The machine therefore does not have appreciable torque pulsations and harmonic losses and the operation is smooth and efficient.

4.The cycloconverter is capable of power transfer in either direction between an ac source and motor load. It can feed power to a load of any pl. Regeneration is inherent in the complete speed range. A four quadrant operation is simple and straight forward.

5.It requires many thyristors, which offset the advantage of line commutation. However, if a thyristor fails no shut down is required. The output can be made available without any interruption, with a slightly distorted waveform.

The increased cost and complex control of a cycloconverter can be justified, for large horsepower applications. The above features of a cycloconverter fed induction motor drive show that it provides a very smooth low speed operation with the least torque ripple. Thus it is very attractive for a low speed, large power, reversible drive. This drive finds application in gearless cement mill, or ball mill drives. The mill drive is directly connected to the motor which is supplied by a low frequency cycloconverter.