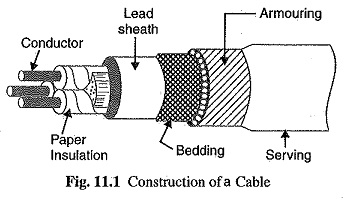

Construction of Underground Cables:

Fig. 11.1 shows the general Construction of Underground Cables. The various parts are :

Cores or Conductors:

A cable may have one or more than one core (conductor) depending upon the type of service for which it is intended. For instance, the 3-conductor cable shown in Fig. 11.1 is used for 3-phase service. The conductors are made of tinned copper or aluminium and are usually stranded in order to provide flexibility to the cable.

Insulation:

Each core or conductor is provided with a suitable thickness of insulation, the thickness of layer depending upon the voltage to be withstood by the cable. The commonly used materials for insulation are impregnated paper, varnished cambric or rubber mineral compound.

Metallic sheath:

In order to protect the cable from moisture, Conductor gases or other damaging liquids (acids or alkalies) in the soil and atmosphere, a metallic sheath of lead or aluminium is provided over the insulation as shown in Fig. 11.1

Bedding:

Over the metallic sheath is applied a layer of bedding which consists of a fibrous material like jute or hessian tape. The purpose of bedding is to protect the metallic sheath against corrosion and from mechanical injury due to armouring.

Armouring:

Over the bedding, armouring is provided which consists of one or two layers of galvanised steel wire or steel tape. Its purpose is to protect the cable from mechanical injury while laying it and during the course of handling. Armouring may not be done in the case of some cables.

Serving:

In order to protect armouring from atmospheric conditions, a layer of fibrous material (like jute) similar to bedding is provided over the armouring. This is known as serving.

It may not be out of place to mention here that bedding, armouring and serving are only applied to the cables for the protection of conductor insulation and to protect the metallic sheath from mechanical injury.