Use of Power Capacitor:

In most of the industrial applications, the power requirements are reactive in nature and a lagging current is drawn from the power lines. This requires additional generating capacity. This can be compensated by using capacitors which take a leading current in a.c. circuits. Hence the greatest Use of Power Capacitor is with the power frequency systems. Capacitors are made in simple units with voltage ratings for 220 to 13800 V with kVAR ratings varying from 0.5 to 25 kVAR. Power capacitors are normally made using impregnated paper dielectric.

Use of Power Capacitor are also used for high frequency applications, such as power factor correction in high frequency heaters and induction furnaces. At high frequencies the dielectric losses increase very rapidly, and the capacitors have to be cooled externally using water cooling. Capacitors are also used in d.c. applications such as impulse voltage generators, energy storage, welding and high intensity flash x-ray and light photography.

Generally, Use of Power Capacitor are made of several layers of insulation paper of adequate thickness and aluminium foil of 6 microns thickness as electrodes interleaved and wound. Single units are connected in parallel depending on the rating of the capacitor unit to be manufactured. These are placed in containers hermetically sealed, thoroughly dried, and then impregnated with insulating oil.

The impregnating oils used are either mineral oil or chlorinated diphenyl oil. Capacitors made with mineral oil are quite expensive, and hence capacitors made with chlorinated diphenyl are pieferred for power factor correction applications because of their low cost and non-inflammability.

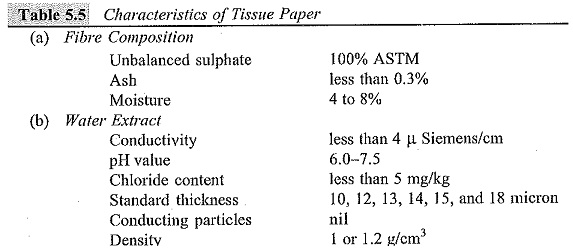

Properties required for the insulation paper for Use of Power Capacitor are high dielectric strength, low dielectric loss, high dielectric constant, uniform thickness, and minimum conducting particles. The recently discovered of polypropylene film has low dielectric loss and higher operating voltage. However, paper is still widely used partly, mainly due to the reason that paper after impregnation offers many desirable properties required for use at high voltages in addition to economy.

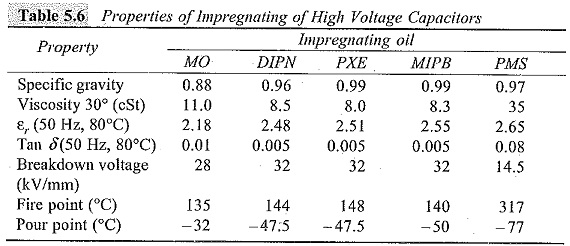

The impregnants for power capacitors should have high dielectric strength, high dielectric constant, good chemical and thermal stability and adequate viscosity for efficient conduction of heat. Mineral oils with high aromatic content have traditionally been used. However, they have been replaced by a variety of synthetic oils such as di-isopropylnaphthalene (DIPN), mono-isopropylbiphenyl (MIPP) and phenylxylenhane (PXE) because of their high gas absorbing abilities, high dielectric strength and dielectric constant.

Properties of some of these impregnants used in capacitors are summarized in Table 5.6. The dielectric properties of the tissue paper and the capacitor impregnants are given in Table 5.5 and 5.6.

MO:Mineral Oil

DIPN:Di-Isopropyl Naphthalene

PXE:Phenylxyl ethane

MIPB:Mono Isopropyl Biphenyl

PMS:Phenylmethyl Dimethyl Siloxane

The electrode material extensively used in aluminium foil of 6 microns thickness because of its high tensile strength, low specific resistance, high melting point, low specific gravity, low cost and, easy availability.

As already mentioned, the latest trend in capacitor manufacture is to replace paper by polypropylene plastic films. This results in a drastic reduction in size. Its use results in cheaper capacitors for high voltage ratings because of its high working stress. As regards impregnants, askarels are harmful to the environment and hence are being banned. The latest trend is to develop other types of material. With this in view, research is being directed towards the use of vegetable oils like castor oil.