Turgo Turbine Working Principle:

The Turgo turbine is an impulse water turbine designed for medium head applications. Operational Turgo Turbines achieve efficiencies of about 87%. It works with net heads between 15 and 300 m. It is a modification of the Pelton wheel, the Turgo Turbine has some advantages over Francis and Pelton designs for certain applications.

First, the runner is less expensive to make than a Pelton wheel. Second, it doesn’t need an airtight housing like the Francis. Third, it has higher specific speed and can handle a greater flow than the same diameter Pelton wheel, leading to reduced generator and installation cost. Turgos operate in a head range where the Francis and Pelton overlap. While many large Turgo installations exist, they are also popular for small hydro where low cost is very important. Like all turbines with nozzles, blockage by debris must be prevented for effective operation.

Working of Turgo Turbine:

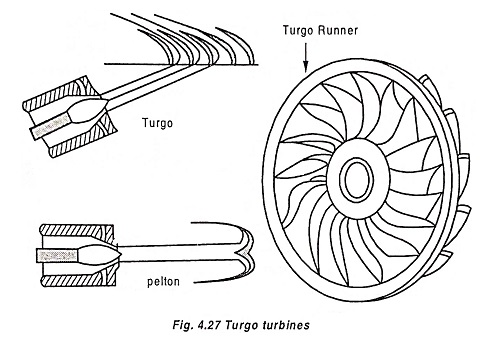

The Turgo turbine is an impulse type turbine; water does not change pressure as it moves through the turbine blades. The water’s potential energy is converted to kinetic energy with a nozzle. The high speed water jet is then directed on the turbine blades which deflect and reverse the flow. The resulting impulse spins the turbine runner, imparting energy to the turbine shaft. Water exits with very little energy. Turgo runners are extremely efficient.

A Turgo runner looks like a Pelton runner split in half. For the same power, the Turgo runner is one half the diameters of the Pelton runner, and so twice the specific speed. The Turgo Turbine can handle a greater water flow than the Pelton because exiting water doesn’t interfere with adjacent buckets.

Load factor:

The load factor is the amount of power used divided by the amount of power that is available if the turbine were to be used continuously. Unlike technologies relying on costly fuel sources, the ‘fuel’ for hydropower generation is free and therefore the plant becomes more cost effective if run for a high percentage of the time. If the turbine is only used for domestic lighting in the evenings then the plant factor will be very low. If the turbine provides power for rural industry during the day, meets domestic demand during the evening and pumps water for irrigation in the evening, then the plant factor will be high.

It is very important to ensure a high plant factor if the scheme is to be cost effective and this should be taken into account during the planning stage.

Load control governors:

Water turbines, like petrol or diesel engines, will vary in speed as load is applied or relieved. This speed variation will seriously affect both frequency and voltage output from a generator. Traditionally, complex hydraulic or mechanical speed governors altered flow as the load varied, but recently an electronic load controller (ELC) has been developed to increase the simplicity and reliability of modern micro-hydro sets. The ELC prevents speed variations by continuously adding or subtracting an artificial load, so that the turbine is working permanently under full load. A further benefit is that the ELC has no moving parts, and hence virtually maintenance free.

Electrical power from micro hydro plant:

Machines can be driven directly by a turbine as in traditional grain mills and many modern timber sawing mills, but converting the power into electricity has several additional advantages. Because it enables the use of all types of electrical appliances from lighting to electric motors and also the flexibility of having the appliances at any point either near or far from the turbine. The device which converts mechanical energy into electrical energy is called a generator. The most common type of generator produces alternative current and is known as an alternator.

Two types of current are produced by electrical generators, either Alternating Current (AC) or Direct Current (DC). In the case of AC, the voltage cycles are sinusoidal with time, from positive peak value to negative. Because the voltage changes its sign, the resulting current also continually reverses direction in a cyclic pattern. DC current flows in a single direction as the result of a steady voltage. DC is not usually used in modern power installations except for very low-powered systems of a few hundred watts or less.

Alternating voltage can be produced in a stationery coil or armature by a rotating magnetic field, but mostly a coil is rotated in a stationery magnetic field. The magnetic field can be produced either by a permanent magnet or by another coil (i.e., an electro-magnet) known as a field coil which is fed by direct current known as the excitation current. A generator supplying alternative current (AC) is described as an alternator and the machine supplying DC current is known as a DC generator or dynamo. Current flows when a voltage difference is placed across a conducting body. In AC circuits, the magnitude and timing of the Current cycle relative to the voltage cycle will depend on the conductivity body resistance, inductive, capacitive or some combination of these elements.

Economics of micro hydel plant:

Normally, small-scale hydro installations in rural areas of developing countries can offer considerable financial benefits to the communities served, particularly where careful planning identifies income-generating uses for the power.

The major cost of a scheme is for site preparation and the capital cost of equipment. In general, unit cost decreases with a larger plant and with high heads of water.

It could be argued that small-scale hydro technology does not bring with it the advantages or ‘economy of scale’, but many costs normally associated with larger hydro schemes have been ‘designed out’ or ‘planned out’ of micro hydro systems to bring the unit cost in line with bigger schemes. This includes such innovations as:

- Using run-of- the river schemes – away with the cost of an expensive dam for water storage.

- Locally manufactured equipment where ever possible and appropriate.

- Use of HDPE (plastic) penstocks where ever appropriate.

- Electronic load controller – allows the power plant to be left unattended, thereby reducing labour costs and introduce useful by-products such as battery charging or water heating as dump loads for surplus power; also does away with bulky and expensive mechanical control gear.

- Using existing infrastructure, for example, a canal which serves an irrigation scheme.

- Setting of power source close to village to avoid expensive high voltage distribution equipment such as transformers.

- Using Pumps As Turbines (PAT) – in some circumstances, standard pumps can be used ‘in reverse’ as turbines; this reduces costs, delivery time and makes for simple installation and maintenance.

- Using motors as generators – as with the PAT idea, motors can be run ‘in reverse’ and used as generators; pumps are usually purchased with a motor fitted and the whole unit can be used as a turbine/generator set.

- Use of local materials for the civil works.

- Use of community labour.

- Good planning for a high plant factor and well balanced load pattern (energy demand fluctuation throughout the day).

- Low-cost connections for domestic users.

- Self-cleaning intake screens – this is recent innovation which is fitted to the intake weir and prevents stones and silt from entering the headrace canal; this does away with the need for overspill and desilting structures along the headrace canal and also means that, in many cases, the canal can be replaced by a low-pressure conduit buried beneath the ground – this technology is, at present still in its early stages of dissemination. Maintenance costs (insurance and water abstraction charges, where they apply) are a comparatively minor component of the total – although they may be an important consideration in marginal economic

Low cost grid connection:

Where the power from a micro-hydro scheme is used to provide domestic electricity, one method of making it an affordable option for low-income groups is to keep the connection costs and subsequent bills to a minimum. Often, rural domestic consumers will require only small quantity of power to light their houses and run a radio or television. There are a number of solutions that can specifically help low-income households to obtain an electricity connection and help utilizes meet their required return on investment.

These include:

(a) Load limited supply

Load limiters work by limiting the current supplied to the consumer to a prescribed value. If the current exceeds that value, then the device automatically disconnects the power supply. The consumer is charged a fixed monthly fee irrespective of the total amount of energy consumed. The device is simple and cheap and does away with the need for an expensive metre and subsequent meter reading.

(b) Reduced service connection costs

Limiting load supply can also help reduce costs on cable, as the maximum power drawn is low and so smaller cable sizes can be used. Also, alternative cable poles can sometimes be found to help reduce costs.

(c) Pry-fabricated wiring systems

Wiring looms can be manufactured ‘ready to install’ which will not only reduce costs but also guarantee safety standards.

(d) Credit

Credit schemes can allow householders to overcome the barrier imposed by the initial entry costs of grid connection. Once connected, energy savings on other fuels can enable repayments to be made. Using electricity for lighting, for example, is a fraction of the cost of using kerosene.

(e) Community involvement

Formation of community and co-operatives who are pro-active in all stage of the electrication process can help reduce costs as well as provide a better service. For example, community revenue collection can help reduce the cost of collection for the utility and hence the consumer.