Explain Vapour Compression Refrigeration System:

Vapour Compression Refrigeration System is the most important system from the standpoint of commercial and domestic utility and most practical form of refrigeration. The working fluid, known as a refrigerant, used in this vapour compression refrigeration system readily evaporates and condenses or changes alternately between the vapour and liquid phases without leaving the refrigerating plant. During evaporation it absorbs heat from the cold body and in condensing or cooling or liquifying it rejects heat to the external hot body. The heat absorbed from cold body during evaporation is used as its latent heat for converting it from liquid to vapour. Thus a cooling effect is created in the working fluid. This system of refrigeration, thus act as a latent heat pump since it pumps its latent heat from the cold body or brine and rejects it or deliver it to the external hot body or the cooling medium. According to the laws of thermodynamics, this can be done only on the expenditure of energy which is supplied to the system in the form of electrical energy driving the compressor.

Advantages:

The main advantages of this vapour compression refrigeration system over the other systems are the smaller size for a given refrigerating capacity (except for some recent development in air refrigeration system in the aircraft cooling), higher coefficient of performance or lower power requirements for a given capacity and less complexity in both design and operation. It can be used over a large range of temperatures.

Disadvantages:

The main disadvantages like toxity, inflammability and leakage of vapours have largely been eliminated by improvements in design resulting in greater safety and prevention of leakages and by development of non-toxic, nonflammable vapours to be used as refrigerants.

The vapour compression cycle is used in most of the modern refrigeration systems in large industrial plants requiring the rapid removal of large quantities of heat and in most of the domestic refrigerators. The vapour in this cycle is circulated through the various components of the system, where it undergoes a number of changes in its state or condition. Each cycle of operation consists of the four fundamental changes of state or processes (i) expansion (ii) vaporisation (iii) compression and (iv) condensation.

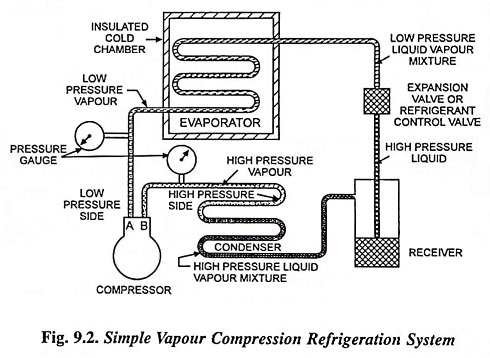

The schematic diagram of a Vapour Compression Refrigeration System is shown in Fig. 9.2. It consists of the following five essential parts.

1. Compressor: The low pressure and temperature vapour refrigerant from evaporator is drawn into the compressor through the inlet or suction valve A, where it is compressed to a high pressure and temperature. The high pressure and temperature vapour refrigerant is discharged into the condenser through the delivery or discharge valve B.

2. Condenser: The condenser or cooler consists of coils of pipe in which the high pressure and temperature vapour refrigerant is cooled and condensed. The refrigerant, while passing through the condenser, rejects its latent heat to the surrounding condensing medium which is normally air or water. Thus hot refrigerant vapour received from compressor is converted into liquid form in condenser.

3. Receiver: The condensed liquid refrigerant from the condenser is stored in a vessel, known as receiver, from where it is supplied to the expansion valve or refrigerant control valve.

4. Expansion Valve or Throttle Valve: The function of this valve is to allow the liquid refrigerant under high pressure and temperature to pass at a controlled rate after reducing its pressure and temperature. Some of the liquid refrigerant evaporates as it passes through the expansion valve, but the greater portion is vaporised in the evaporator at the low pressure and temperature.

5. Evaporator: An evaporator consists of coils of pipe in which the liquid vapour refrigerant at low pressure and temperature is evaporated and changed into vapour refrigerant at low pressure and temperature.

During evaporation process, the liquid vapour refrigerant absorbs its latent heat of vaporization from the medium (air, water or brine) which is to be cooled.