Explain Vapour Absorption Refrigeration System:

The vapour absorption refrigeration system is one of the oldest method of producing refrigerating effect. The refrigerant, commonly used in this system, is ammonia. This system uses heat energy, instead of mechanical energy as in vapour compression systems, in order to change the conditions of the refrigerant required for the operation of the refrigeration cycle.

Working Principle:

In the vapour absorption refrigeration system, the compressor is replaced by an absorber, a pump, a generator and a pressure reducing valve. These components in vapour absorption refrigeration system, perform the same function as that of a compressor in vapour compression refrigeration system, already discussed. In this system, the vapour refrigerant from the evaporator is drawn into an absorber where it is absorbed by the weak solution of the refrigerant forming a strong solution. This strong solution is pumped to the generator where it is heated by some external source. During the heating process, the vapour refrigerant is driven off by the solution and enters into the condenser where it is liquified. The liquified refrigerant then flows into the evaporator and thus the cycle is completed.

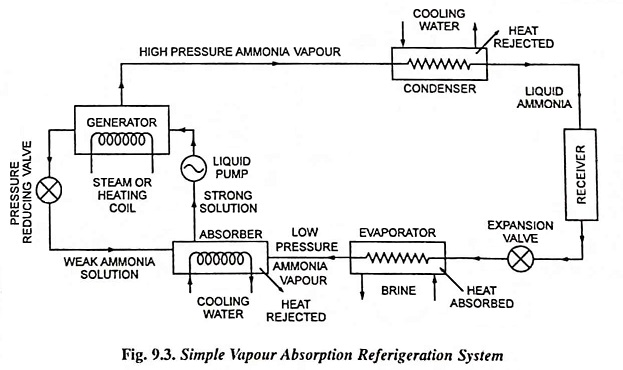

The simple vapour absorption refrigeration system is shown in Fig. 9.3. It essentially consists of an absorber, a pump, a generator and a pressure reducing valve, in addition to condenser, receiver, expansion valve and evaporator, as in the vapour compression refrigeration system.

In this system. the low pressure ammonia vapour leaving the evaporator, enters the absorber where it is absorbed by the cold water. The water has the ability to absorb very large quantity of ammonia vapour and the solution so formed, is known as aqua-ammonia. The absorption of ammonia vapour in water lowers the pressure in the absorber which in turn draws more ammonia vapour from the evaporator and thus the temperature of the solution is raised. Some form of cooling arrangement (usually water cooling) is used in the absorber for removal of heat from the solution evolved there. This is necessary so that the absorption capacity of the water is increased. The strong solution thus formed in the absorber is pumped to the generator by the liquid pump. The pump increases the pressure of the solution up to 10 kg/cm2.

The strong solution of ammonia in the generator is heated by some external source such as gas or steam. During the heating process, the ammonia vapour is driven off the solution at high pressure leaving behind the hot weak ammonia solution in the generator. This weak ammonia solution flows back to the absorber at low pressure after passing through the pressure reducing valve. The high pressure ammonia vapour from the generator is condensed in the condenser to a high pressure liquid ammonia. The liquid ammonia is passed to the expansion valve through the receiver and then to the evaporator. Thus the simple absorption cycle is completed.

Advantages and Applications:

This system has a least number of moving parts. They are quite in operation and are used both in commercial as well as in domestic installations. In recent years, they have been used extensively in recreation vehicles, camper-trailers and boats as portable units due to their operation from a small gas cylinder.