Carbon Arc Welding – Working Principle, Advantages and Applications:

Carbon arc welding differs from metal arc welding in that it is a puddling process and is somewhat similar to the gas welding process. The carbon arc is very stable and easy to maintain. The length of the arc can be varied over wide limits without causing the arc to go out. There is no tendency for the electrode to freeze or stick, as in the case of the metallic electrode. Accordingly the arc can be struck without difficulty at any point, and rapidly moved over the surface of the work to the point where the weld is to be made. High melting speed and efficient welds are the main advantages claimed.

Working Principle:

In this process, a carbon or graphite rod is used as a negative electrode and the work being welded as positive. Mostly graphite electrodes are used as they yield longer life and have low resistance and thus capable of conducting more current. The arc produced between the two electrodes heats the metal to the melting temperature. This is about 3,200°C on the negative electrode, and 3,900°C on the positive electrode.

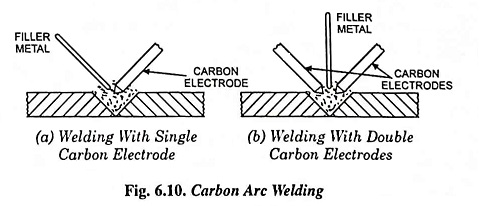

The reason to use carbon rod as negative electrode is that less heat will be generated at the electrode tip than that at the workpiece, and carbon from the electrode will not fuse and mix up with the job. If this so happens the resultant weld will be rich in carbon, and consequently very much brittle and unsound. For this type of welding only dc can be used. The use of ac is not recommended because no fixed polarity can be maintained. This process is normally adopted where addition of filler material is not required. e.g., flange or edge joints, but if filler metal is required, it is provided by the welding rod made of the similar metal to that of the metal to be welded. Some protection for the molten weld metal may be provided by using a long arc which produces a carbon monoxide gas envelope. There are two methods of carbon arc welding. In one method no flux is used and in the other method flux either in the form of powder or paste is used to prevent the weld from oxidation. Former method is confined to non-ferrous metals and the later method is usually employed for ferrous metals.

Electrodes up to 25 mm in diameter with currents up to 600 or 800 A are used, so that the carbon arc process is well suited to rapid work, or cases such as arise in the repair of castings, where large quantities of filler metals have to be deposited.

Applications:

Carbon arc welding is employed for welding sheet steel, copper alloys, brass, bronze, and aluminium. It is not suitable for vertical and overhead welding.

In another process of carbon arc welding, known as twin carbon arc welding, two carbon electrodes are used between which the arc is formed, as illustrated in Fig. 6.10 (b). In this way the arc generates heat which is applied close to the parts to be welded, causing the edges to fuse. In heavy welds, a filler rod is melted by the arc and deposited in the weld. An ac supply is recommended for twin carbon arc welding. In case dc supply is used, the positive electrode will disintegrate and consume at a much faster rate as compared to the -ve electrode because two-thirds of the total heat is generated at the positive pole. This will produce an unstable arc and need more frequent adjustment of the electrodes. The electrodes used for twin carbon arc welding are approximately of the same diameter as the thickness of workpiece. The magnitude of arc current required depends upon both, electrode diameter and plate thickness.

Advantages of Carbon Arc Welding:

Twin carbon arc welding, though, more complex than single carbon arc welding, possesses the advantage that arc is independent of the job and can be moved anywhere without getting extinguished. Moreover, the workpiece is not a part of the electrical circuit.