Composite System of Track Electrification:

The composite system of track electrification which comprise are

- the dc system

- the single phase ac system

- the three phase ac system and

- the composite system

- single phase-three phase system and

- single phase-direct current system.

1. DC System

In this system of track electrification, the electric motors employed for getting the necessary motive power are usually dc series motors, although the compound motors are coming into favour for tramways and trolley buses where regenerative braking is desired. The operating voltage is from 600 volts to 750 volts for tramways and for many suburban railways and from 1,500 volts to 3,000 volts for main line railways. The driving motors receive power from distribution system, (in dc as well as single phase ac system). The distribution system consists of one contact wire in case of tramways and two contact wires in case of trolley buses (the running rail acts as current returning conductor in case of tramways) which is fed from substations (except in case of very short railways where a direct supply from a dc generating station may be possible) suitably spaced. The spacing of the substations depends upon the operating voltage and the traffic density of the route. For suburban railways where the operating voltage is 600 volts the substations are spaced 3 to 5 km apart and for main line railways having

operating voltage of 1,500 to 3,000 volts they may be spaced 15 to 40 km. These substations receive ac power from a 3-phase high voltage (33 to 132 kV) transmission lines and convert it into direct current either by rotary convertors or by mercury-arc rectifiers or thyristor converters with suitable transformation ratio. These substations are usually unattended type using supervisory control system. This arrangement reduces the cost of transmission lines and copper losses in transmission lines. As regards the merits and demerits of dc system the dc motors have better characteristics, low maintenance cost and a smaller weight per kW output, better speed control, and efficient regenerative braking but because of low operating voltage conductor of large x-section for the distribution system and more number of substations spaced at shorter distances for feeding the distribution system are required for a given service. The cost of substations is also more due to heavy cost of converting machinery required for converting ac into dc and of additional equipment such as negative boosters etc. required to keep the voltage of return rail within limits.

The dc system is preferred for suburban services and road transport where stops are frequent and distances of run are small.

2. Single Phase AC System

In single phase ac system ac series motors are used for getting the necessary motive power. The voltage employed for distribution network is 15,000 to 25,000 volts at 16 2/3 or 25 Hz, which is stepped down on the locomotive to a low voltage (300 to 400 V) suitable for supplying to single phase ac series motors by means of a step-down transformer carried on the locomotive. The distribution network may be fed directly, at high voltage, from a generating station when the extent of system of track electrification is within a radius of about 30 km from the generating station. For longer distances the economic voltage for the power transmission system is higher than that desirable for traction system, and therefore, transformer substations are employed for feeding the distribution network. The spacing of substations is 50 to 80 km because of low current requirement at high voltage. The substations receive power at high voltage either from the existing extra high voltage transmission lines or from a separate system employing single phase generating stations and steps down the voltage to the required value and/or change the supply frequency through frequency convertors. The change of supply frequency becomes necessary because of better performance of the ac series motors at low frequency. Low frequency operation of ac series motor improves its commutation properties, power factor and efficiency. Low frequency operation of overhead transmission line reduces the line reactance and hence the voltage drop directly.

In case the supply at low frequency is obtained directly from a generating station exclusively meant for traction purposes, there is no problem as power corresponding to this frequency can always be generated. If, however, electric supply is taken from industrial frequency network, which is usually the case, substations in addition to transformers have necessarily the frequency converters to convert 3-phase, 50 Hz into single phase 16 2/3 or 25 Hz as required.

AC single phase system is invariably adopted for main line service where the cost of overhead structure is of more importance and rapid acceleration and retardation is not so important as for suburban railways.

3. Three Phase AC System

In this system 3-phase induction motors operating at 3,000 to 3,600 volts and normal frequency of 16 2/3 Hz are employed for getting the required motive power. The three phase induction motors are simple and robust in construction and have a high operating efficiency and property of automatic regenerative braking without requiring any additional equipment. However, the induction motors have few drawbacks such as low starting torque, high starting current and absence of speed control. The distribution system consists of two overhead wires and track rail for the third phase and receives power either directly from the generating station or through the transformer substations. The substations receive power from high voltage transmission lines at power frequency and step down the voltage and change the frequency. Since two trolley wires per track are necessary, the line voltage of the distribution systems has to be limited to values below the highest voltage used for single phase railways, and as the 3-phase induction motors can be built economically for operation at moderately high voltage, the line voltage is usually chosen so that the motors may be supplied directly from the trolley wires. This system is employed in some hilly areas, where output power required is high and regeneration on large scale is possible. On account of disadvantages of two overhead contact wires and constant speed characteristic of induction motors this system is no longer likely to be adopted.

4. Composite Systems

Efforts have been made to combine the advantages of the dc/ac and 3-phase/single-phase systems and composite systems have been evolved. The single phase ac sysem is preferable from the viewpoint of the distribution and contact wire system. It can be converted into either three-phase ac or dc at low voltage in the locomotive. At present there are two composite system of track electrification in vogue.

- Kando system or single phase-to-three phase system.

- Single phase ac-to-dc system.

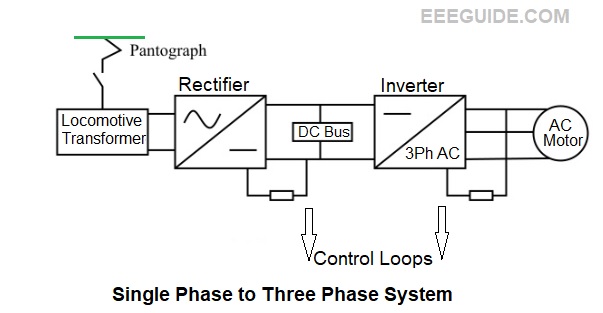

(a) Single Phase-To-Three Phase System or Kando System

In this system single phase high voltage ac system is employed for distribution purposes and three phase induction motors for getting the necessary motive power in order to have the advantage of low cost of single phase overhead distribution system together with desirable characteristics of three phase induction motors. The voltage used for distribution network is 15,000 volts at 50 Hz. The locomotive carries a phase convertor for converting single phase supply into 3-phase supply at relatively low frequency. The development of silicon controlled rectifier (SCR) used as invertor has made possible to get variable low frequency supply (1/2 to 10 Hz) at which induction motor develops high starting torque without drawing excessive current from the system and speed control is also conveniently obtained by varying the supply frequency. There exists good possibility of this traction system to develop for further adoption.

(b) Single Phase-To-Direct Current System

In this system the advantages of the two systems are combined together by employing high voltage ac single phase system for overhead distribution and dc series motors for the necessary drive so that high efficiency of the ac distribution system is obtained together with the desirable characteristics of dc series motors. The locomotive carries transformer and converting machinery to step down the voltage and convert into dc. The voltage employed for overhead distribution system is 25 kV at normal supply frequency of 50 Hz. This system is adopted in all the areas of major traffic density on main lines. It has been decided to adopt this system of traction employing 25 kV, industrial frequency (50 Hz) ac supply for system of track electrification in our country and this is being installed on sections which are being electrified.

This system of track electrification has got numerous advantages over dc system as enumerated below:

- The line current for a given demand of power is reduced on account of high system voltage. It causes reduction in the cross section of overhead conductor which leads to a saving in the cost of supporting structures and their foundations being lighter in weight and simpler. This fact will be obvious from the following datas: The weight of copper required per track km for the 1,500 V dc system is 3,700 kg and for the 3,000 V dc system is 3,300 kg whereas for ac system it is 1,600 kg. The weight of steel required per track km in ac system is only about half of that required for dc system.

- On account of high voltage the substations can be spaced at longer distances (50 to 80 km) whereas the substations are spaced at 12 to 30 km in case of 3,000 V dc system and at 5 to 12 km in case of 1,500 V dc system. It affects substantial saving in the capital expenditure on traction substations and transmission lines on account of reduced number of substations to be erected and flexibility offered in the location of site for substations. AC substations are simpler and cheaper than dc substations as they only have step-down transformers and associated switchgear.

- A very special feature of the ac locomotive in comparison with the dc locomotive is the greater amount of adhesion obtained with ac locomotive. In the case of ac rectifier locomotive employing dc traction motors, coefficient of adhesion is obtained as much as 45% against the value of 27% in case of dc locomotives. The greater adhesion is obtained because of possibility of connecting of all dc series motors in parallel permanently and controlling their speeds by varying the voltage across each motor by tap changing auto-transformer on the ac side. In this system slipping of a particular motor does not affect the voltage across the remaining motors and so adhesion is maintained but in case of dc traction employing resistance and series—parallel control slipping of a particular motor throws its load on the other motor which may reduce the voltage across the other motor and may, therefore, cause slipping of this motor also. The increase in coefficient of adhesion increases the hauling capacity of the locomotives (75 tonne ac locomotive can haul the same load as the 110 tonne dc locomotive).

- The starting efficiency of an ac locomotive is higher than that of a dc locomotive as in case of ac locomotive supply voltage for starting is reduced by means of ‘on-load tap changer’ installed on either the primary or the secondary side of the transformer where as in case of dc locomotive it is obtained by using starting resistors. Elimination of starting bulky resistors not only increases the starting efficiency but also makes the torque-speed curve more steep and thus improves adhesion. This in turn increases the power-weight ratio in the case of ac locomotives.

- Since the dc series motors having ideal traction characteristics are employed in this system for getting the required propelling power, therefore, this system have got the advantages of the dc system.

- AC locomotive has less kW demand at starting than that of a dc locomotive owing to elimination of starting resistances in ac locomotives. This is of particular importance at peak traffic hours specially when a number of locomotives are to be started simultaneously after an interruption of supply.

There are, however, some drawbacks with the single phase ac system such as unbalance imposed on the power supply system and interference with neighbouring communication lines. Fortunately both of the shortcomings can be minimised by taking suitable precautions such as

- Taking of supply for the traction substations at very high voltage (say 132 or 220 kV) and from a supply system having high capacity.

- Balancing of traction loads equally on all the three phases which is possible by connecting different traction substations across different phases in rotation.

- Employing the Scott or T-connected three phase/two phase transformers in the traction substations.

- Replacing of open aerial communication lines by lead or aluminium sheathed underground cables and earthing the sheathing of the cables at regular intervals.

- Providing of isolating transformers which reduce the induced voltages and keep them below 60 V under operating conditions.

- Making use of booster transformer and return conductor for suppressing interference at the source in case of thickly populated areas.