What is Electroplating in Electrolysis and its Working Principle

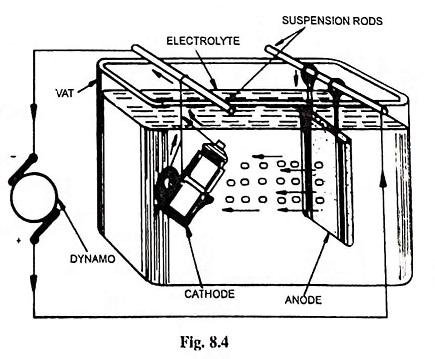

Electroplating is an art of depositing a superior or a more noble metal on an inferior or a base metal by means of electrolysis of an aqueous solution of a suitable electrolyte. For example, metals like iron which are easily corroded by atmospheric air, moisture and carbon dioxide, are coated electrolytically with deposits of nickel or chromium which are more resistant to chemical attack. Picture frames and machinery parts are often chromium-plated to protect them from corrosion and at the same time to give them a good polish.

Sometimes, electroplating is done, with a view to repair worn-out parts of a machinery. In such electroplating cases the suitable material is deposited electrolytically on the effected parts of the machinery.

Electroplating is also done occasionally for ornamentation and decoration purposes. For example, several articles made of copper or its alloys, such as tablewares, decoration pieces, are coated with silver or gold.

The electrolytic deposits are crystalline in nature. The crystals must be very fine in order to get firm, coherent and uniform deposits. For this purpose, suitable electrolytes should be used in the electrolytic bath and current density used should have an appropriate value. The temperature should also be maintained at a proper level. By experiments, a certain optimum value of current density and temperature have been worked out for each electrolyte. For example, for Na3 [Cu(CN)4] bath, the optimum current density lies between 32-65 A/m2 and optimum temperature is 45°C. The optimum conditions for [Ag(CN)2] bath, are 42 A/m2 of current density and 20°C as the temperature. The articles to be coated with the noble metals should be in as high a state of purity as possible. These conditions are briefly discussed below.

Preparation For Plating

The preparation of an object for plating may involve any or all of the following operations :

- Removal of oil, grease, or other organic material.

- Removal of rust, scale, oxides, or other inorganic coatings adhering to the metal.

- Mechanical preparation of the surface of the metal to receive the deposited metal, by polishing, buffing etc.

For the first, soaps, hot alkali solutions, or organic solvents such as gasoline or carbon tetrachloride are used, for the second, various acids, alkali and salt solutions, mechanical abrasion, and electrolytic cleaning, and for the third mechanical abrasion and polishing are used.

Cleaning Methods

In case the object to be electroplated is not cleaned, polished and degreased, the deposit formed may not be well adherent to the base metal and is likely to peel off. For smooth, bright and strong deposit, the surface upon which a layer of a noble metal is required, should be thoroughly cleaned first mechanically by grinding or scratching (against a rough surface) or sandblasting and then chemically by treatment with hot alkalies (if the surface is greasy) or with dilute acids (if the surface has oxide films) or with organic solvent.

Electrolytic Bath

The electrolyte used in the electrolytic bath depends upon the nature of the metal to be deposited.

For copper plating two types of electrolytic baths are used. In acid type bath, solution is made of 150-200 gm of copper sulphate and 25-35 gm of sulphuric acid per 1,000 cc of solution. Current density used is 150-400 A/m2 and temperature of 25 to 50°C. Deposit obtained is thick and rough requiring polishing. In cyanide bath solution is made of 25 gm of copper cyanide, 28 gm of sodium cyanide, 6 gm of sodium carbonate and 6 gm of sodium bisulphate per 1,000 cc of solution. Current density used is 50-150 A/m2 and the temperature required is 25-40°C. It provides thin and smooth deposits. Copper anodes are used in both of the baths.

For silver plating solution consisting of 24 gm of silver cyanide, 24 gm of potassium carbonate and 36 gm of potassium cyanide per 1,000 cc is used. The required current density and temperature are 50-150 A/m2 and temperature of 20-35°C respectively.

For gold plating solution used consists of 18 gm of potassium gold cyanide, 12 gm of potassium cyanide, 6 gm of potassium sulphate and 12 gm of caustic potash per 1,000 cc Anode employed is of stainless steel. Current density of 50-150 A/m2 and temperature of 50-70°C are used.

For chromium plating solution most commonly used consists of 180-300 gm of chromic acid and 2-3 gm of sulphuric acid per 1,000 cc. Current density employed is 1,500-2,500 A/m2 and the working temperature is 35-50°C. Current density used is higher for hard chromium plating than for decorative plating. Anodes are of antimonial lead. Vats used for chromium plating are of steel with lead lining. Chromic acid is added in the solution when required. Arrangements for removal of the fumes are also to be provided.

For nickel plating the solution consists of 180-240 gm of nickel sulphate, 36 gm of nickel chloride and 24 gm of boric acid per 1,000 cc. The current density used is 100-200 A/m2. The working temperature is 25-40°C. Anode is of pure nickel.