Dielectric Heating – Working, Advantages and Applications:

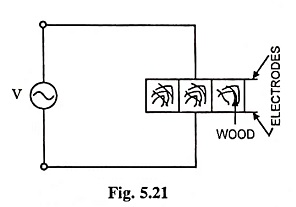

When non-metallic parts such as wood, plastics, bones are subjected to an alternating electrostatic field dielectric loss occurs. In dielectric heating use of these losses is made. The material to be heated is placed as a slab between metallic plates or electrodes connected to high frequency ac supply. For producing sufficient heat frequency between 10 and 30 MHz is used. Even though voltage up to 20 kV have been used but from personnel safety point of view voltages between 600 V and 3 kV are in common use. The necessary high-frequency supply is obtained from a valve oscillator, as in the case of high frequency eddy current heating, explained already. An overall efficiency is about 50%.

The current drawn by the capacitor, when an ac supply voltage is applied across its two plates, does not lead the supply voltage by exactly 90° and there is always an in-phase component of the current. Due to this in-phase (or active) component of current, heat is always produced in the dielectric material placed in between the two plates of the capacitor. The electric energy dissipated in the form of heat energy in the dielectric material is known as dielectric loss. The dielectric loss is directly proportional to the frequency of ac supply given to the two plates of the capacitor. The physical conception of the dielectric loss is just as a molecular friction in the dielectric material when an ac electrostatic field is applied to it.

Insulators being poor conductors cannot be heated up quickly from outside. In dielectric heating the heat is produced within the material itself. Because heat generation is uniform, the dielectric material is heated uniformly. This is the important property of dielectric heating.

In insulators or non-conducting materials, the amount of heat produced by dielectric heating can be calculated as follows :

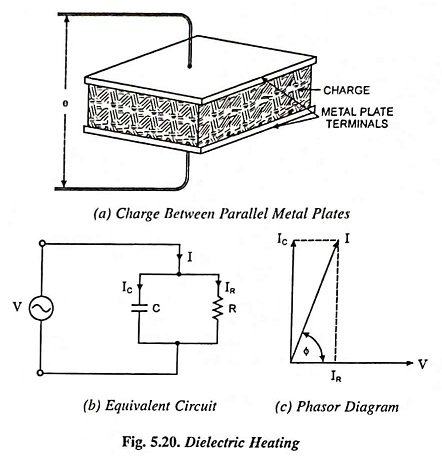

The material to be heated may be considered as the imperfect dielectric of a condenser and may be, therefore, represented as a capacitance placed in parallel with a resistance, as shown in Fig. 5.20 (b). The phasor diagram of the circuit is shown in Fig. 5.20 (c). If V is supply voltage in volts, f is supply frequency in Hz, C is the capacitance of the condenser in farads and cos Φ is power factor of the load or charge,

Current through the capacitor,

where C is in farads and V is in volts.

The current drawn from supply,

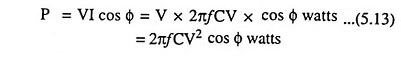

Power produced,

The value of power factor for a particular non-conducting material is constant, and the capacity is determined from the dimensions of plates, the charge which serves as the dielectric medium and the dielectric constant. Therefore, the dielectric heating depends upon the values of the frequency and the voltage. By varying one of these two quantities, the rate of dielectric heating can be varied. The insulation problem limits the voltage to be used; hence to achieve more heat, high frequency is used. However, there is a limit also, on the high frequency, imposed by cost involved in getting a circuit for obtaining very high frequencies and other difficulties.

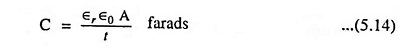

The capacity of the condenser can be calculated from the following relation

where

- εr is relative permittivity of dielectric,

- ε0 is absolute permittivity of vacuum and equals 8.854 x 10-12 F/m,

- t is the thickness of dielectric in metres and

- A is the surface area of plates in m2.

Advantages:

- If the material to be heated is homogeneous, and the alternating (or varying) electric field is uniform, heat is developed uniformly and simultaneously throughout the entire mass of the charge.

- As materials heated by this process are non-conducting, so by other methods heat cannot be conducted to inside so easily.

Applications:

The cost of the equipment required for dielectric heating is so high that it is employed only where other methods are impracticable or too slow. Some of the applications of dielectric heating are given below.

1. Preheating of Plastic Preforms: The raw material in the form of tablets or biscuits, commonly called plastic preforms, is required to be heated uniformly before putting them into the hot moulds so that whole mass becomes fluid at a time, otherwise if the raw material is put directly into the moulds, usually heated by steam, the outer skin of the preforms will become hot and start curing while the core of the material has not reached fluid temperature resulting in unequal hardening of the plastic and improper filling of moulds corners. Difficulty arises due to the fact that plastic raw material once cured cannot be softened again satisfactorily. Any method of heating depending upon conduction of heat from surface to the core would miserably fail because plastic is bad conductor of heat. Dielectric heating is the only method which can be used for preheating of plastic preforms to proper temperature uniformly.

2. Gluing of Wood: Dielectric heating is most commonly used for gluing of wooden sheets or boards as in this method of gluing the moisture contents of the wooden sheets remain unaltered. It is due to the fact that heat can be applied to the desired surface. Main difficulty in using animal glues is of long curing time and that parts to be joined are to be kept under mechanical pressure after application of glue for a period of about 24 hours. Mechanical pressure may be applied in gluing of wood by dielectric heating in order to secure better adhesion. Because of higher loss factor of glue as compared to that of wood most of the heat developed goes into the glue and very little heat is wasted.

High frequency dielectric heating is very economical for obtaining curved wood sections such as furniture. The curves obtained by this method are stable.

3. Baking of Foundary Cores: In foundaries resin type thermosetting binders are employed as they set almost instantaneously when brought to polymerizing temperature. The dielectric heating evaporates water rapidly from the core mix and at the same time raises the temperature of the core material to polymerization point. Hence dielectric heating is most suitable for baking foundary cores mixed with thermosetting resin type core binders.

4. Diathermy: Dielectric heating is also employed for heating tissues and bones of the body required for the treatment of certain types of pains and diseases.

5. Sterlization: The dielectric heating is quite suitable for sterilization of bandages, absorbent cotton, sterile gauge, instruments etc.

6. Textile Industry: In textile industry the dielectric heating is employed for drying purposes.

7. Electronic Sewing: Nowadays rain coats, umbrellas, food containers, medicine containers etc. are made from plastic film materials. In case of ordinary stitching by thread they will be no longer water tight and also become weak at seam. With adhesives curing times will be longer. In case of electronic sewing the films to be stitched are rolled in between cold rollers to which radio-frequency voltage is applied. The heat produced in the material seals it all along the line where mechanical pressure is applied. The cold rollers prevent the outer surface of the films from being softened.

8. Food Processing: The use of dielectric heating for food processing is one of the most modern method. It has brought many advantages for the food processing industry and has set forth such processes which are outside the realm of cooking. The dielectric heating can be appreciably employed for the following purposes :

- Pasteurising of milk and beer inside bottles.

- Dehydrating of fruits, milk, cream, vegetables and eggs etc.

- Cooking of foods without removing the outer shells.

- Defrosting of frozen foods such as meat and vegetables.

- Germicidal heating—In dielectric heating process the products do not loose flavour.

Disinfestation of cereals and grains—Dielectric heating may be used to destroy the eggs of insects and pests saving grains and cereals from damage and also to prevent these eggs, larva or moth etc. to pass on to cereal processing equipment and develop into dangerous worms later on under favourable conditions of temperature and humidity.