Amplidyne (Rotary Amplifier) – Definition, Construction, Connection Diagram, Workings and Applications:

The amplidyne is a rotary amplifier in which a small amount of power supplied to excite the field is amplified in the generator output. Though the ordinary separately excited generator operated at low flux densities can be used as a power amplifier since the power required for exciting the field is only 1 to 3 per cent of the rated output of the generator and a small change in the power to the field can be made to produce a large proportionate change in the power output. However, a much larger power amplification can be had by using the amplidyne, since in this machine power is amplified in two stages. Rotary amplifiers are generally built for outputs up to 100 kW.

This machine uses the cross-field principle and a single two-pole armature winding.

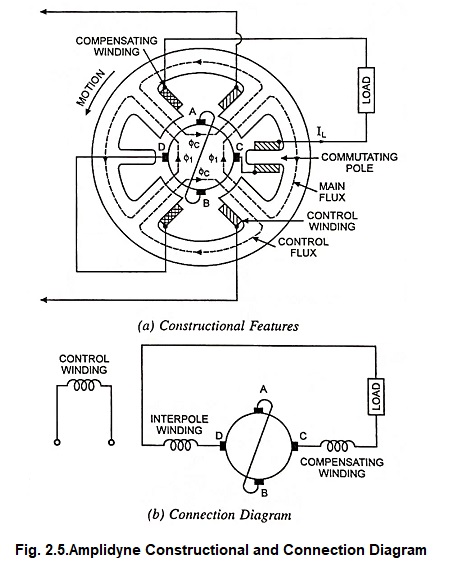

The basic constructional features for a 2-pole armature amplidyne are shown in Fig. 2.5 (a). The poles, however, are divided and give the appearance of a four-pole field though actually the poles are in pairs with the same polarity. The poles may be salient ones as used in ordinary dc machines or may be slotted so as to take a distributed winding. The machine is sometimes termed a split-field machine because it has divided poles. Commutating poles may be arranged in all the interpolar gaps. Control windings and compensating windings are arranged, as illustrated in Fig. 2.5 (a). Compensating winding in the form of a concentrated coil wound around the field cores, as shown in Fig. 2.5 (a) is used in many cases but such a winding does not completely neutralize the armature load current mmf and some distortion of the flux, therefore, exist. For better compensation a distributed type of compensating winding, properly located in slots in the pole faces must be used. The magnetic circuit may then consist of slotted punchings. This form does not provide as much space for a variety of field windings as the form with polar projections, and the various control inputs are more usually combined in an electronic or magnetic amplifier providing the control excitations instead of in the machine itself. Magnetic circuit should be of laminated construction throughout.

The action of the machine is now explained. The control windings produce a small control flux Φc in the horizontal axis. When the machine is driven, a voltage is developed between the short-circuited brushes A and B and, therefore, current flows between them (the control winding is provided with few ampere-turns in order to limit the current through the short-circuited armature winding). Now the current I1 through the short-circuited armature winding produces armature reaction flux at right angles to the control flux Φc which in turn develops emf between the output brushes C and D. In the figure separate flux paths have been shown. Although the fluxes are superimposed in the poles and parts of the armature and yoke, in the absence of saturation they are mutually independent.

When the amplidyne is loaded, load current IL flows which in turn sets up the flux opposing the control flux Φc. It is essential, therefore, for the armature reaction mmf set up by the output current IL to be neutralised if the machine is to operate as a high-gain amplifier. A compensating winding is, therefore, connected in series with the power output brush terminals. The machine operated in this manner is called the amplidyne. This device is virtually two machines in one. Current through the short-circuited brushes which form the load for the first stage, acts also as the field excitation for the second stage. Mechanical input at the shaft is converted into an electrical output, modulated by the control flux. With full compensation, gains of the order of 20,000 : 1 are possible and the power supplied to the control winding may be fraction of a watt even in a 10-20 kW rated machine. Hence the amplidyne can be fed directly from an electronic amplifier in an automatic control scheme.

The basic machine, described above, had only one control winding, which was separately excited. Actual amplidynes are provided with additional field windings separately excited as well as self excited to provide desirable characteristics. Separately excited field windings are called the control windings since the energy or signals, as they are generally called, which are supplied to the control windings control the machine output. Since these windings are of very small power capacity, a small change of input power to a control field winding will develop a large change in the output voltage across brushes C and D and, therefore, a large change in power output. It is feasible to construct amplidynes with four separate control field windings so that the output of the machine may be controlled from several independent signals. Commutating poles are fitted at the brush axis to assist commutation, but it is not usual to fit them at the cross axis, except in large machines owing to the small value of I1, the exciting current.

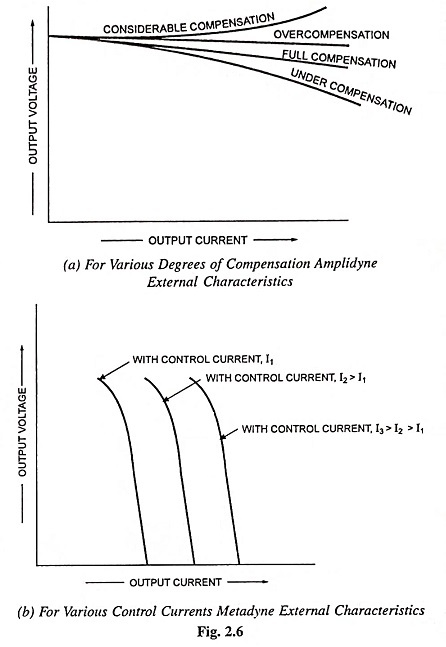

The external characteristic of an amplidyne is similar to that of an ordinary separately excited generator, but its slope can be regulated by acting on the compensating winding of the amplidyne. This winding is usually designed to provide magnetizing force somewhat greater than the demagnetising force of armature reaction of the amplidyne i.e., to overcompensate for the armature reaction, which is necessary under certain amplidyne operating conditions. But usually the compensating winding is shunted by a rheostat to reduce the magnetising force. This allows the slope of the external characteristic to be regulated. In the case of under compensation, the voltage drop, with increasing load, will be due not only to the voltage drop in the armature, but also to armature reaction.

In the case of full compensation of armature reaction a fall in the amplidyne voltage with increasing load will be due only to voltage drop in the armature. With slight overcompensation, an increase in flux with the load can be made to compensate exactly for the increase in voltage drop in the amplidyne armature, in which case the voltage of the amplidyne will not vary with the load. However, in the case of extreme overcompensation, undesirable self excitation of the amplidyne i.e., spontaneous rise in voltage and load current at constant control current (or with the control circuit open) can occur. Such self-excitation (similar to that of generator) can continue until saturation of the amplidyne magnetic system becomes effective. Self excitation can cause considerable overloading of the amplidyne and totally disrupt operation of the system containing the amplidyne.

In partial compensated machine the opposing flux produced by the output current IL would neutralize most of the control flux. In control engineering terms, it is a negative current feedback tending to suppress any increase of output current. The action is sufficient to maintain the output current almost constant regardless of change in load resistance. The machine operated in this way is called the Metadyne. In such cases electrical input and output powers are the same, neglecting copper losses and the only mechanical power that is required to overcome the mechanical losses. The output current is controlled by the current through control windings. The output characteristics of Metadyne with different control currents are shown in Fig. 2.6(b).

Note : From the characteristics shown in Figs. 2.6(a) and 2.6(b) for amplidyne and metadyne respectively it is obvious that an amplidyne should never be operated on short circuit and a metadyne on open circuit.

Metadyne Generator Rating

The rated output power of a metadyne is appreciably less than that obtainable from the same armature in a normal generator. First; the output current has to be reduced by about 10 per cent, owing to the heating caused by the quadrature current I1 flowing in the armature. Secondly the provision of the commutating zones for two sets of brushes reduces the effective pole-face area, and hence the total flux and terminal voltage by about one-third. The rated output power of the armature is thus about 0.9 x 2/3 = 0.6 of that of the same armature in an ordinary dc generator. For this reason it is not economical to use metadynes for large output power, and, above 15 to 20 kW separately excited dc generators are employed with metadynes as exciters to provide similar results as from a metadyne generator.

Applications of Amplidynes

An amplidyne is widely used for various purposes, particularly in feedback control systems where the regulated power requirement is in the range of 1 to 50 kW. It may sometimes be found economical to employ it as a voltage regulator in the excitation system of a large alternator to buck or boost voltage in series with the field winding of the main exciter. It can also be employed as a generator in a Ward-Leonard system of speed or position control. In modern control systems these functions of an amplidyne have been taken over by SCR circuitry.

Amplidynes are employed in installations for controlling reversing rolling mills, cold rolling mills, mine hoists, metal cutting and paper machines. However, amplidynes posses a number of shortcomings: poor commutation, which sometimes disrupts the operating conditions of the installation, and a low efficiency of operation. There is a trend in industry to replace amplidynes by static devices, such as magnetic amplifiers operating in conjunction with transistor amplifiers.