Applications in Circuit Breaker:

Applications in Circuit Breaker : A circuit breaker is a switch which automatically interrupts the circuit when a critical current or voltage rating is exceeded. A.c. currents are considerably easier to interrupt than d.c. currents. A.c. current interruption generally requires first to substitute an arc for part of the metallic circuit and then its deionization when the current goes through zero, so that the arc will not reestablish again.

Applications in Circuit Breaker are also divided into two categories, namely, the low voltage and high voltage types. Low voltage breakers use synthetic resin mouldings to carry the metallic parts. For higher temperatures ceramic parts are .used. When the arc is likely to come into contact with moulded parts, melanine or some special kind of alkyd resins are used because of their greater arc resistance.

Nowadays most of the Applications in Circuit Breaker that are in operation use SF6 gas or vacuum as insulating medium. While vacuum circuit breakers are available up to voltage ratings of 33 kV, SF6 circuit breakers are manufactured up to the higher transmission voltage of 800 kV. Most of the present-day SF6 circuit breaker designs are virtually maintenance free. This means that the arcing contacts and nozzles on the interrupters should have a long service life. Most arcing contacts are fitted with copper-tungsten alloy chips. This alloy is used to control both the erosion rate of the tips and the emission of copper vapour from the contacts.

The nozzle is the most important component of a buffer type interrupter. The performance of the interrupter is governed by the nozzle geometry, shape, size and nozzle material. The materials normally chosen are either very pure PTFE or filled PTFE. Pure PTFE can produce carbon molecules absorbing the radiated arc energy. Filled PTFE gives better performance than pure PTFE. There are three types of filling materials used to make filled PTFE, they are, boron nitride, molybdenum and aluminium oxide. Although filled PTFE is slightly more expensive than pure PTFE, its consistent performance and extra long life justifies its use in high current interrupters. Further, epoxy and polyurethane and other polymeric materials are being widely used for potting, encapsulation and mouldings to replace other traditional materials in Applications in Circuit Breaker and transformers.

Arc Interruption in Circuit Breaker:

Pure SF6 gas is very efficiently used in the present-day circuit breakers for interrupting currents up to 63 kA and 80 kA. However, it is an expensive gas and at the normal operating pressure of 6 bar (g), it condenses at temperatures lower than – 20°C. Therefore several gas mixtures have been studied with the objective of effectively using them in switchgear. One such mixture is SF6/N2 whose dielectric strength, is 80% of that of pure SF6, but its interrupting performance does not compare favourably with that of pure SF6 gas. The short circuit rating of SF6/N2 circuit breaker is normally lower, i.e. its value reduces to 40 kA from 50 kA for an SF6 insulated circuit breaker.

With circuit breakers for voltage of 550 kV the number of interrupters per phase has reduced from 6 to 1 in recent years. Therefore, the dielectric performance has become very important. In Applications in Circuit Breaker, due to the very high temperatures produced during interruption, SF6 gas decomposes into its various constituents, some of which are toxic. Long-term resistance of the insulating material to SF6 decomposition products is essential and therefore most manufacturers use alumina-filled cast resin insulators.

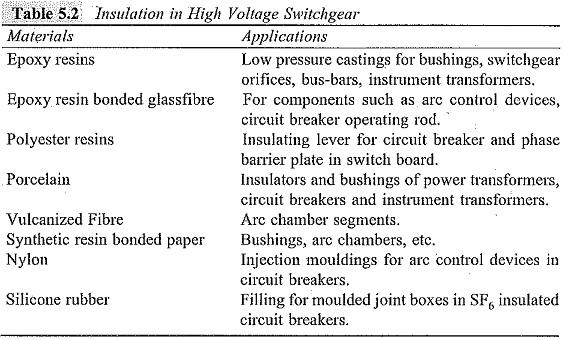

The different types of insulating materials used in the construction of high voltage switchgear are classified in Table 5.2. This includes some of the modern insulating materials for future applications. Of these, a few are widely Used as major insulants. They are, procelain, synthetic resin bonded paper laminates, epoxy resins, SF6 gas and vacuum.