Automatic Combustion Control System:

Automatic Combustion Control System is very popular nowadays and this has been developed mainly to maintain load against demand, to prevent smoke, to increase boiler house efficiencies, to carry out routine adjustments and to provide interlocking safeguards.

If we want to change the rate of combustion, then the draught, air supply and fuel supply have to be regulated. The draught and air supply depend on fans and it can be regulated either by dampers and vanes. The fuel supply can be regulated according to the firing method employed.

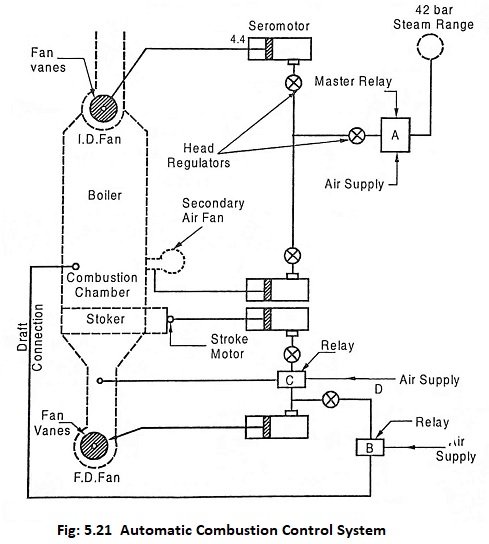

An automatic combustion control system is shown in Fig.5.21.

The operation of the system is controlled by a master relay, ‘A’ which is sensitive to small variations in steam pressure and is connected to the system of 42 bar range. When the steam pressure falls, this drop in pressure makes the relay ‘A’ to operate the servomotor coupled to the vanes of ID fan, causing this to open slightly. And at the same time, the secondary air fan damper is opened at a proportionate amount.

With the change in the induced draft, the stabilized condition in the furnace is changed. This, in turn, alters the position of FD fan servomotor by means of the relay ‘B’. The position of the FD fan vanes is adjusted until the stabilized condition in the furnace is re-established. This change causes extra air to flow past the pilot-tube D which operates relay ‘C’ causing the motor of the stoker to speed up at a proportionate amount and supply extra amount of fuel to the furnace. An increase in pressure is the reverse of the above process. Each servomotor can be adjusted manually to make its action to be advanced (or) retarded. The master relay ‘A’ has hand control which allows the manual control of the whole combustion system.

The combustion control regulates the flow of fuel and air in order to generate the required amount of steam in accordance with the steam load. Fuel feeding is controlled by varying the speed of coal feeder. Air flow is controlled by positioning the damper in the primary air inlet ducts and inlet vanes of forced draft fans.

Feed water control is activated to regulate the flow of feed water to the boiler. The quantity of feed water flowing to the boiler will depend upon the steam requirements. The feed water flow is measured by a nozzle fitted in the feed water discharge pipe.

Flow of steam through a stationary turbine is usually regulated in order to produce constant rotative speed in the presence of variable load demand. Control is activated by varying the quantity and pressure of steam flowing through the turbine.