Binary Vapour Cycle – Schematic Diagram and its Workings:

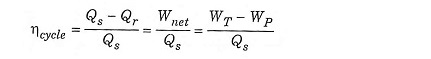

The maximum efficiency is achieved in carnot cycle.

To increase the efficiency of the actual engine, ie to approach the carnot cycle efficiency, the total heat should be supplied at constant temperature T1 and rejected at T2. This can be achieved only by using wet vapour and not by using superheated vapour.

The thermal efficiency depends on only higher temperature T1 since lower temperature T2 is fixed by the natural sink to which heat is rejected. So T1 should be maximum to the possible extent.

Mercury, Diphenyl ether (C6 H5)2 O, Aluminium bromide and Ammonium chloride are the working fluids having desirable thermodynamic properties like high critical temperature and low critical pressure. Among the above fluids, mercury is having desirable high critical temperature (588.4 °C) and low critical pressure (21 bar).

But we can not use mercury alone since its saturation temperature at atmospheric pressure is high (357°C). So binary vapour cycle using two fluids – mercury and water are used to increase the thermal efficiency.

The mercury vapour leaving the mercury turbine is condensed and the heat released during this condensation is utilized to heat and evaporate the feed water to become steam and this steam is expanded in the steam turbine to produce work. Mercury turbine also produces work.

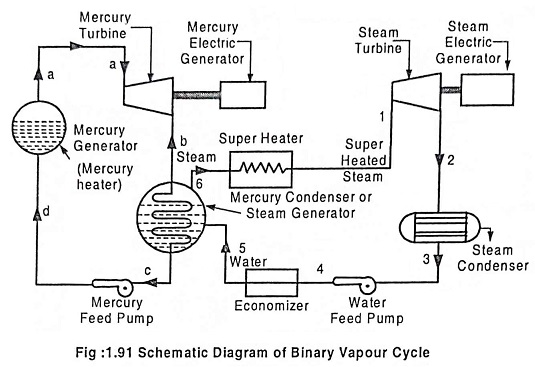

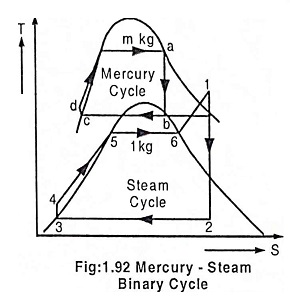

Thus, two fluids, mercury and water are used in binary vapour cycle. Heat rejected by mercury is utilized by water in this cycle. The schematic diagram of binary vapour cycle is shown in Fig.1.92. T.S. diagram is also shown.

Refer the diagram. The binary vapour cycle consists of mercury cycle and water (steam) cycle.

Mercury Cycle (Topping Cycle):

The mercury cycle a b c d is a simple Rankine cycle. In this cycle, mercury is expanded in the mercury turbine (process a – b) and work is produced. The mercury leaving the mercury turbine is condensed (process b – c) in the mercury condenser (steam generator) where heat is released to heat and evaporate the feed water into steam. The condensed mercury is pumped (process c – d) to mercury generator. Thus mercury cycle is completed.

Steam Cycle (Bottoming Cycle):

As already stated, the heat rejected in the mercury condenser heats and evaporates the (process 5 – 6) feed water into steam. This steam is further heated by external sources in the superheater (process 6 – 1) and become superheated steam. This superheated steam is expanded in the steam turbine (process 1-2) and is then condensed (process 2 – 3). The condensate (feed water) is thus pumped (process 3 – 4), and is then preheated in the economizer (process 4 – 5) and is then sent to mercury condenser (or) steam generator and thus steam cycle is completed.

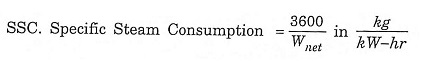

Heat supplied

Heat rejected

Turbine work

Pump work

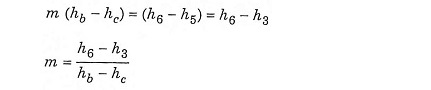

Heat rejected by mercury = Heat absorbed by water to become steam.