Chopper Control of Separately Excited DC Motor:

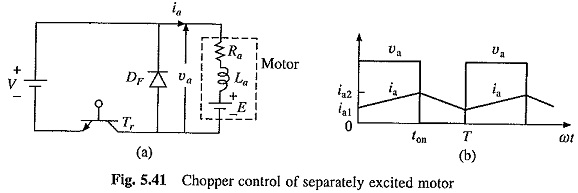

Motoring Control : A transistor Chopper Control of Separately Excited DC Motor drive is shown in Fig. 5.41(a). Transistor Tr is operated periodically with period T and remains on for a duration ton. Present day choppers operate at a frequency which is high enough to ensure continuous conduction. Waveforms of motor terminal voltage va and armature current ia for continuous conduction are shown in Fig. 5.41(b). During on-period of the transistor, 0 ≤ t ≤ ton, the motor terminal voltage is V.

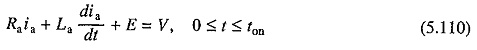

The operation is described by

In this interval, armature current increases from ial to ia2. Since motor is connected to the source during this interval, it is called Duty Interval.

At t = ton, Tr is turned-off. Motor current freewheels through diode DF and motor terminal voltage is zero during interval ton ≤ t ≤ T. Motor operation during this interval, known as freewheeling interval, is described by

Motor current decreases from ia2 to ia1 during this interval.

Ratio of duty interval ton to chopper period T is called duty ratio or duty cycle (δ). Thus

From Fig. 5.41(b)

Equation (5.2) and (5.7) are also applicable here

From Eqs. (5.7), (5.8). and (5.114)

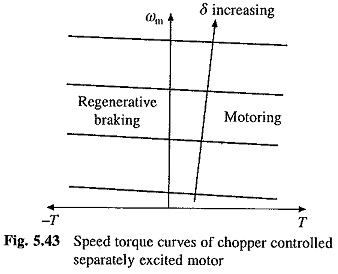

The nature of speed torque characteristic is shown in Fig. 5.43.

Regenerative Braking:

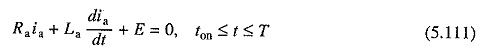

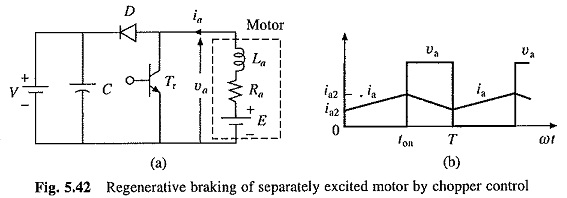

Chopper Control of Separately Excited DC Motor for regenerative braking operation is shown in Fig. 5.42(a). Transistor Tr is operated periodically with a period T and on-period of ton. Waveforms of motor terminal voltage va and armature current ia for continuous conduction are shown in Fig. 5.42(b). Usually an external inductance is added to increase the value of La. When Tr is on, ia increase from ia1 to ia2.

The mechanical energy converted into electrical by the motor, now working as a generator, partly increases the stored magnetic energy in armature circuit inductance and remainder is dissipated in armature resistance and transistor. When Tr is turned off, armature current flows through diode D and source V, and reduces from ia2 to ia1. The stored electromagnetic energy and energy supplied by machine is fed to the source. The interval 0 ≤ t ≤ ton is now called energy storage interval and interval ton ≤ t ≤ T the duty interval. If δ is again defined as the ratio of duty interval to period T, then

From Fig. 5.42(b)

and from Fig. 5.42(a)

Since la has reversed

From Eqs. (5.8), (5.118) and (5.119)

The nature of speed torque characteristic is shown in Fig. 5.43.

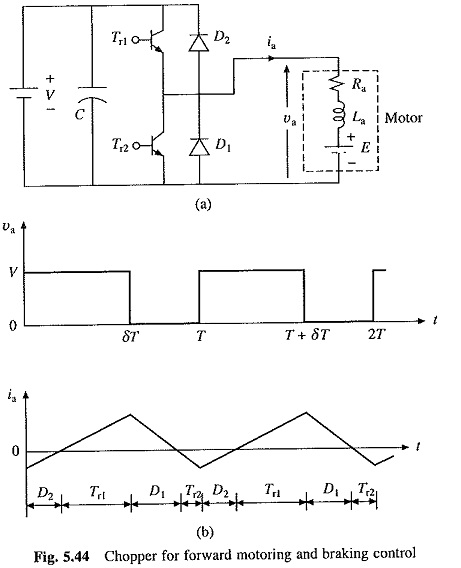

Motoring and Regenerative Braking:

Chopper circuits of Figs. 5.41 and 5.42 can be combined to get a two quadrant chopper of Fig. 5.44, which can provide motoring and regenerative braking operations in the forward direction. Transistor Trl with diode D1 form a chopper circuit similar to that of Fig. 5.41, and therefore, provide control for forward motoring operation. Transistor Tr2 with diode D2 form a chopper circuit similar to that of Fig. 5.42, and therefore, provide control for forward regenerative braking operation. Thus, for motoring operation transistor Trl is controlled and for braking operation transistor Tr2 is controlled. Shifting of control from Trl to Tr2 shifts operation from motoring to braking and vice versa.

In servo drives where fast transition from motoring to braking and vice versa is required, both Trl and Tr2 are controlled simultaneously. In a period T,Trl is given gate drive from 0 to δT and Tr2 is given gate drive from δT to T, where δ is the duty ratio for Trl. Therefore, from 0 to δT motor is connected to source either through Trl or D2 depending on whether the motor current ia is positive or negative. Since V > E, during this period the rate of change of current is always positive. Similarly from δT to T, motor armature is shorted either through D1 or Tr2 depending on whether ia is positive or negative and during this period rate of change of current is always negative. Motor terminal voltage and current waveforms are shown in Fig. 5.44 (b).

From Fig. 5.44(b)

Above equation suggests that motoring operation (+ve Ia) takes place when δ > (E/V) and regenerative braking operation takes place when δ < (E/V) and transition from motoring to braking and vice versa occurs when δ = (E/V). The above equations are similar to those obtained for chopper of Fig. (5.41), and therefore, given the same numbers

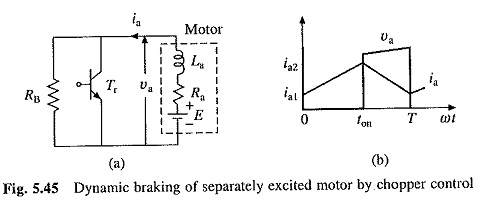

Dynamic Braking:

Dynamic braking circuit and its waveforms are shown in Fig. 5.45. During the interval 0 ≤ t ≤ ton, ia increases from ia1 to ia2. A part of generated energy is stored in inductance and rest is dissipated in Ra and Tr. During interval ton ≤ t ≤ T, ia decreases from ia2 to ia2. The energies generated and stored in inductance are dissipated in braking resistance RB, Ra and diode D. Transistor Tr controls the magnitude of energy dissipated in RB, and therefore, controls its effective value.

If ia is assumed to be rippleless dc, then energy consumed EN by RB during a cycle of chopper operation is

Average power consumed by RB

Effective value of RB

where

Equation (5.122) shows that the effective value of braking resistor can be changed steplessly from 0 to RB as δ is controlled from 1 to 0. As the speed falls, δ can be increased steplessly to brake the motor at a constant maximum torque as shown in Fig. 5.8 by chain-dotted line.