Cogeneration Power Plant | Topping and Bottoming Cycle in Cogeneration:

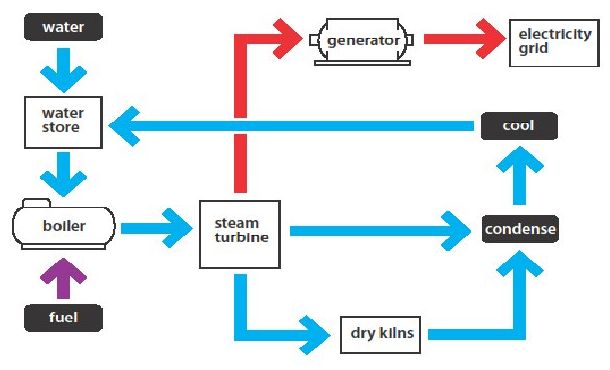

Considering the tremendous amount of waste heat generated in thermal power generation, it is advisable to save fuel by the simultaneous generation of electricity and steam (or hot water) for industrial use or space heating. Now called Cogeneration Power Plant, such systems have long been common, here and abroad.

Currently, there is renewed interest in these because of the overall increase in energy efficiencies which are claimed to be as high as 65%.

Cogeneration Power Plant is highly energy efficient and is particularly suitable for chemicals, paper, textiles, food, fertilizer and petroleum refining industries. Thus these industries can solve energy shortage problem in a big way. Further, they will not have to depend on the grid power which is not so reliable. Of course they can sell the extra power to the government for use in deficient areas. They may also sell power to the neighboring industries, a concept called wheeling power.

As on 31.12.2000, total co-generation potential in India is 19,500 MW and actual achievement is 273 MW as per MNES (Ministry of Non-Conventional Energy Sources, Government of India) Annual Report 2000-01.

There are two possible ways of Cogeneration Power Plant of heat and electricity:

- Topping cycle,

- Bottoming cycle.

In the topping cycle, fuel is burnt to produce electrical or mechanical power and the waste heat from the power generation provides the process heat. In the bottoming cycle, fuel first produces process heat and the waste heat from the processes is then used to produce power.

Coal-fired plants share environmental problems with some other types of fossil-fuel plants; these include “acid rain” and the “greenhouse” effect.