Constant Current System for Speed Control of DC Motor:

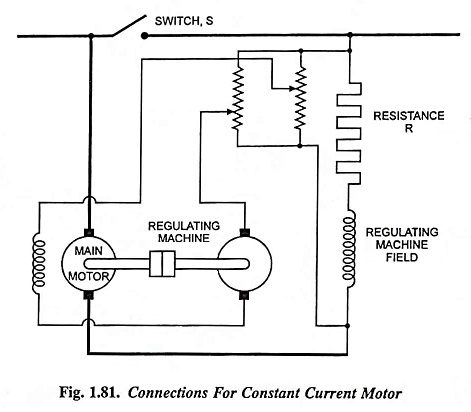

For certain services, where there is a possibility of the motors being stalled such as with excavators, ship’s windlasses etc. the constant current system is advantageous and is used. In this system a dc generator delivering a constant current by means of a special exciter under all load conditions is employed. The current remains the same through out and the voltage varies with the variation in load. The connections are shown in Fig. 1.81.

The field of the main motor is excited from tappings across the resistance R and field winding of the regulating machine so that variable voltage in either direction can be applied to the field system. The regulating machine is mounted on the motor shaft and is so connected in series with the motor field that the emf of the regulating machine opposes the main field current. Any decrease in speed of the motor which may occur due to increase in load, would reduce opposite emf, (emf induced in the regulating machine) and thus field current and torque would increase. The torque would reach maximum when the motor stalls.

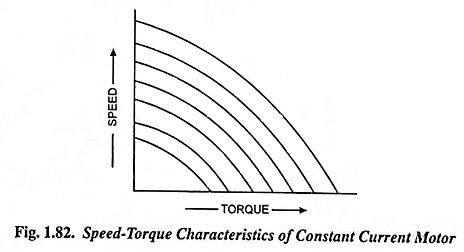

Speed-torque characteristics for the various positions of the potential divider are shown in Fig. 1.82.

A full-range of speed control can be had with the maximum torque when the motor stalls without any excessive current.

Any number of motors can be connected in series with each other as the current is independent of load. Thus cable cost and copper losses are reduced. The motor can be stopped simply by closing switch S.