Different Groups of Systems of Electric Traction:

As already mentioned, systems of electric traction may be divided into two main groups.

(1) The group consisting of vehicles which receive electric power from a distributing network fed at suitable points from either a central power station or substations suitably spaced. This group is further subdivided into:

- Systems operating with dc such as trolley buses, tramways and railways.

- Systems operating with ac, such as railways.

(2) The group consisting of self-contained locomotives. This group is further subdivided into:

- Diesel electric trains and ships.

- Petrol electric trucks and lorries.

- Battery driven road vehicles.

Out of these self-contained electric vehicles, only the diesel systems of electric traction is widely employed and hence keeping in view the limitations discussion will be limited to it.

Tramways

The power is supplied to the tramcar, usually at 600 dc volts, from a single overhead conductor (of positive polarity) fed at suitable points from a central power station or substations, the track rail forms the return conductor. The tramcar is provided with at least two driving axles so that necessary adhesion is secured and control is possible from either end. The use of two or more driving axles lends itself to the use of two motors with series-parallel control. Field weakening method may be employed to obtain higher running speeds for suburban service. Two drum type controllers, one at each end, usually employed for control of vehicle, are connected in parallel but are provided with some suitable interlocking arrangements so that operation is possible from one end at a time. With the increasing outputs required by present-day tramcars the controller is tending to become so large that its operation causes fatigue to the driver, and master controller equipment similar to that used on railways is employed in recent designs. The great disadvantage of the tramway is that it needs laying of overhead supply system and track for its use which is costly to maintain and constitutes a source of danger to other road users. For very dense traffic in large cities the tramway is most economical means of transportation. Nowadays the trolley bus or internal combustion engine omnibus is preferred on account of its greater manoeuvrability. The equipment required for tramcars is similar to that used in railways but of considerably smaller output (not exceeding 45 or 55 kW). Life of tramcar equipment is much more than that of internal combustion engine omnibus. The conditions for regenerative braking are not very favourable but it may be used in hilly areas and on level track up to a speed of 20 kmph. Rheostatic and mechanical brakings are employed for normal service. Mechanical braking is employed when the speed becomes too low that electrical braking becomes ineffective. For mechanical braking, electromechanical drum brakes are employed. Magnetic brakes are also used for providing better retardation. The magnetic brakes are in fact electromagnets suspended on springs. These are attracted to the rail track, where they exert sufficient braking force. Thus dual braking effect is obtained. Tramcars, if provided with magnetic brakes, can be excited by the rheostatic braking current.

Trolley Buses

Serious drawback of tramway is lack of manoeuvrability in congested areas and noise. These are overcome by trolley bus drive. The trolley bus is an electrically operated pneumatic tyred vehicle and is fed usually at 600 dc volts from two overhead contact wires by means of two collectors. Although the overhead equipment required by the trolley buses is more expensive and more unsightly than that for the tram, this drawback is usually more than offset by the elimination of the necessity of the track in the roadway, which is costly to maintain and also constitutes a source of danger to the other road users.

Another advantage of trolley bus is that it is able to manoeuvre in a traffic over a width of several metres on each side of the centre line of the trolley wires. As the adhesion between a rubber-tyred wheel and the roadways is sufficiently high, therefore, only a single driving axle and so a single motor is normally used. A dc compound motor of output of 50 to 100 kW is usually employed.

Speed control is obtained by field weakening (by providing a resistance in the shunt field or the tappings on series field or divertors with the series field) method. Foot operated master controllers are used so that driver may have his hands free to steer the vehicle and apply handbrake. One pedal controls the starting, speed control and regenerative braking if any, and second pedal controls rheostatic and compressed air brakes. Regenerative braking is usually not employed in trolley bus drive because of difficulty of ensuring that supply system is always in a position to absorb the energy regenerated. In order to avoid damage to the power transmission gear, which may occur, in case plain rheostatic braking is used, due to high adhesion between road and rubber tyres, stabilised rheostatic braking is used. The lighting system in the car is low-voltage dc supplied from a motor-generator set connected in parallel with a battery. The vehicles are usually provided with secondary batteries so that the vehicles can be manoeuvered in case of emergency. As the body of the vehicle is insulated from earth because of tyred wheels, care must be taken to ensure adequate insulation resistance. The insulation resistance is checked at the end of the day when it is hot and damp and, therefore, in its worst condition. The trolley bus can accommodate slightly more passengers than an oil engined bus, and because of its high acceleration and braking retardation the schedule speed over a given route will be higher than that of the latter vehicle, so that fewer trolley buses will be required for operating a given service. Trolley buses are, therefore, used for the inner suburbs with medium traffic density.

Although oil-engined buses are more expensive to maintain and operate than a trolley bus, urban and rural services operating with a service interval of more than 15 or 20 minutes are most economically dealt with by these vehicles, as the cost of overhead equipment for a trolley bus service would be too large relative to the number of passengers carried and the revenue earned.

Diesel Electric Traction

The high initial cost of any system of track electrification renders it uneconomical except where the traffic density is high or where heavy grades and loads preclude any other type of traction. Under other conditions self-contained motive power units are required, and these may employ either steam or internal combustion engines as the prime movers. No doubt for road transport the IC engine is supreme but for railway the choice lies between steam and heavy-oil (diesel) engines. The factors governing the choice of traction system are, therefore, largely economic and depend on the natural resources of the country/region concerned. For instance countries (like Denmark, South America and Siam) where fuel has to be imported and water is sometimes scarce, will like to adopt diesel systems of electric traction. The diesel electric traction system is quite economical where the cost of diesel oil is low as in USA. On the other hand countries rich in coal, like Great Britain, may like to have systems of electric traction for urban areas and steam traction for suburban areas. This system is also adopted in the areas where coal for steam engines is not available in plenty and water is also scarce as in Rajasthan. This avoids transportation of large quantities of coal over long distances. Diesel locomotive consumes very small amount of water as compared to steam locomotives.

Diesel locomotives were introduced for the first time in our country in 1945 for shunting purposes on BG sections and in 1956 for main line services on MG sections. Indian Railway started using diesel locomotives extensively for main line services since 1958.

The diesel-electric locomotives employed in practice are of following four types:

- The main-line diesel electric locomotive having engines of output not exceeding, 1,500 kW and speeds 160 kmph.

- The shunting diesel electric locomotive having an engine of 225-375 kW output and speed between 25 to 50 kmph.

- The diesel-electric multiple unit stock of which each motor has an engine of 135-150 kW output and the train is capable of having speeds between 80 to 110 kmph.

- The diesel-electric rail car having an engine of 75-450 kW output which may operate as a single car or with one or more trailer coaches.

In diesel electric traction system the electric motors employed for driving the locomotive are fed from a dc generator driven by the diesel engine put on the same locomotive. Thus diesel electric locomotive is self-contained motive power unit and, therefore, heavy expenditure on track electrification and substations etc, is eliminated.

The diesel engine employed for diesel electric locomotives is usually high speed type with three or four different running speeds with different output power. The generator may be self-excited type or separately excited. In case of a separately excited generator excitation is obtained from an auxiliary generator connected in parallel with the battery, so that standby supply is available. Similarly diesel engine is made self starting employing the supply from the battery. The voltage control of main generator becomes easier.

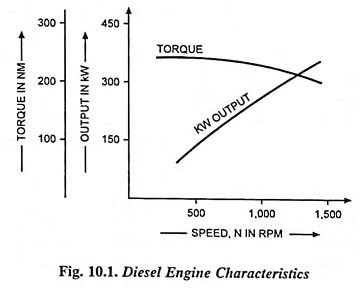

The characteristic of diesel engine is that the torque obtainable is approximately constant and independent of speed and the output power increases fairly uniformly with the speed, as illustrated in Fig. 10.1. It has no starting torque and must be started by some auxiliary means such as compressed air or electrically, as in the ordinary motor car. The overload capacity of the diesel engine is also very small (not exceeding 10%).

The torque required in traction service is roughly inversely proportional to the speed being a maximum at start and at low speeds so that the constant torque characteristic of a diesel engine is not entirely suitable; if such an engine is directly coupled to the driving wheels and made of such a size that it provides the required torque at very low speeds, then at full load it would be loaded up to 20 to 25 per cent of its full load.

Some form of torque converter must, therefore, be included in the transmission between the engine shaft and the driving axles so as to convert the constant torque at full engine speed into a torque which decreases with the increase in speed, maintaining the kilowatts output (proportional to the product of torque and speed) approximately constant and, therefore, enabling the available output of the diesel engine to be used to the full at all speeds.

There are two types of transmission systems which are usually employed.

1. Mechanical transmission system employs a variable gear between the engine shaft and driving wheels as in the ordinary motor car. This method is almost universally employed for road and light railway vehicles but it is not suitable for railway work where output required, exceeds 300 kW due to the mechanical difficulties with the gears and gear changing equipment. This system of transmission of power is light and more efficient than electrical transmission system but it is not so flexible as the latter one.

2. Electrical transmission system employs a diesel engine coupled to a dc generator which supplies current to ordinary dc series motors on the driving axles. This system makes use of the simple speed control properties and desirable speed-torque characteristic of the dc series motors.

Assuming that the diesel engine is running at a constant speed and the generator is giving a constant voltage, any increase in the tractive effort required (say, due to its meeting an up gradient) will reduce the speed of the traction motors owing to their characteristics. The reduction in speed will not, however, be sufficient to compensate for the increased tractive effort, and, therefore, output power required will increase and the engine will be overloaded.

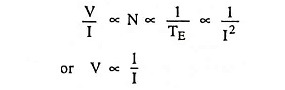

In order that the power delivered by the diesel remains the same, the product of tractive effort and speed i.e., TE x N must remain constant.

Hence speed

But also

and

There, For constant output

Thus the generator voltage must be varied inversely as the current in order to keep the output power required constant.

This is done by employing a series winding on the generator or its exciter, which is so connected in the circuit of traction motor that the increase in traction motor current demagnetises the field. This method does not, however fulfil the above condition very closely and a large number of modifications and additions to it have been developed and employed by different manufacturers to obtain the constant power output curve.

In diesel systems of electric traction the series motors are supplied power directly from the generator instead of through dropping resistance in series as employed in straight systems of electric traction. The starting and speed control is obtained by varying the excitation of the generator.

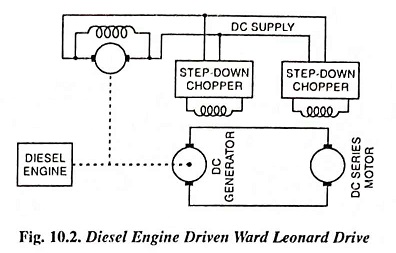

Diesel engine driven Ward Leonard drive is depicted in Fig. 10.2. Such drive employs a non-electrical prime mover (diesel engine or a gas turbine) for driving a dc generator that feeds a dc motor. The generator-motor combination operates as a torque converter, like a stepless gear, to provide to the motor speed-torque characteristics required by the load. The motor runs at variable speed, the prime mover and the generator coupled to it runs at a fixed higher speed resulting in reduced their size and cost and optimized efficiency. Regenerative breaking is not possible because the flow of energy in reverse direction is not possible but the rheostatic braking can be employed if required.

The dc generator speed is restricted to a value because of commutation difficulties. This may not permit the prime mover to be driven at an optimum speed. Further, commutator also imposes restrictions on the maximum power rating of a dc generator. In some large power applications, the generator is to feed a number of motors. The generator, therefore, should be of a size larger than what a dc generator can be. Furthermore, a dc generator needs frequent maintenance because of commutator. All these limitations and problems can be avoided if a synchronous generator and an uncontrolled rectifier bridge are used instead of a dc generator. The voltage across the dc series motor is controlled by varying the excitation of the synchronous generator.

Several electric transmission have been employed, the most common one are :

- Diesel engine driven dc generator feeding traction motors (dc series motors).

- Diesel engine driven three phase synchronous generator feeding traction motors through semiconductor diode rectifier.

- Diesel engine driven three phase synchronous generator feeding three phase squirrel-cage induction motors through semiconductor diode rectifier followed by a 3-phase VSI (voltage source inverter).

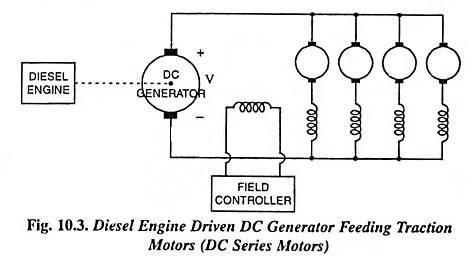

(a) Diesel Engine Driven DC Generator Feeding DC Series Motors. Block diagram of a diesel systems of electric traction using a dc generator and dc series motors is shown in Fig. 10.3. Diesel engine does not have starting torque. It is made self starting employing the supply from the battery to feed the generator.

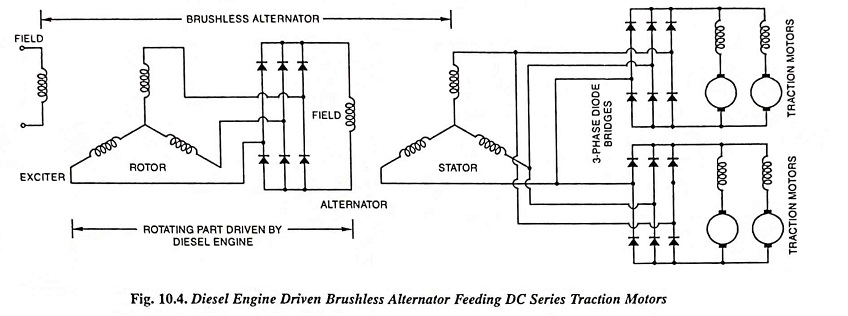

(b) Diesel Engine Driven Three Phase Synchronous Generator Feeding DC Series Motors Through Semiconductor Diode Rectifier. Block diagram of diesel systems of electric traction using brushless alternator and dc series traction motors is shown in Fig. 10.4.

3-Phase synchronous generator is excited by supplying dc into the rotor by means of slip-rings and brushes which need frequent maintenance. The dc series traction motors are fed through two diode bridges. In the scheme shown in Fig. 10.4, slip rings and brushes are eliminated by making use of brushless excitation system. It employs an exciter which is an alternator with inverted rotor and stator functions i.e., field on the stator and three phase winding on the rotor. Exciter is mounted on the alternator shaft. Three phase voltages induced in the exciter rotor are rectified by a diode bridge which is mounted on the rotor shaft, and therefore, revolves with it. The rectified voltage is supplied to the field of synchronous generator. The excitation to alternator is adjusted by controlling exciter field current.

The advantages of this scheme over dc generator scheme shown in Fig. 10.3 are :

- Because of restricted maximum speed, the maximum power rating of a dc generator is low. But with this scheme there is no restriction.

- Because of brushless alternator, maintenance is reduced.

- Transmission efficiency is improved by 2-4%.

- Advantage of good adhesion is retained due to parallel connection of all motors.

- Reduced weight of generating unit (around 50%) brings down the volume and cost of generating unit.

- The scheme is more economical because of reduced maintenance and reduced cost of alternator rectifier.

The only drawback of this scheme is that it needs a separate motor for its starting because the engine cannot be started by this arrangement.

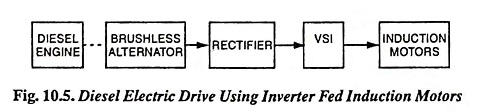

(c) Diesel Engine Driven Three Phase Synchronous Generator Feeding Three Phase Squirrel-Cage Induction Motors Through Diode Bridge and Inverter. The block diagram of diesel electric drive using inverter fed induction motors is shown in Fig. 10.5. Both six-step and PWM inverter can be employed.

With the use of 6-step inverter, voltage is controlled by adjusting field current of alternator and with the use of PWM inverter, voltage is controlled by the inverter itself and the rectifier output voltage can be maintained constant at the rated value. This allows reduction in the current rating of alternator and diode rectifier; further resulting in reduction in the cost, weight and size of the generator unit. A cycloconverter can also be employed instead of diode rectifier and inverter. But the alternator must be driven at a higher speed.

This scheme has the following advantages :

- High power rating, high efficiency due to small power losses and reduced maintenance.

- High ratio of power output to locomotive weight. So heavier trains on faster schedules can be pulled by the locomotive.

- All motors can be connected in parallel providing best condition from the point of view of adhesion.