Domestic Refrigerator Working Principle and Construction:

The applications of refrigeration for domestic purposes are mainly in the form of domestic refrigerator and home freezers.

The main purpose of this type of refrigeration is to provide low temperature for storage and distribution of foods and drinks. It represents a significant portion of the refrigeration industry due to the use of these units in large number.

The growth of food destroying micro-organisms is quite fast (about 100 times) at 10°C than at a temperature lower than 4°C. In order to preserve the fruits, vegetables, fish, meat, milk, medicines etc. against spoilage at higher temperature (generally during summer season), the use of refrigerators is very much emphasized. The storage of perishable products at low temperature greatly reduces the activity of both the enzymes and micro-organisms.

For domestic preservation, the storage is generally short-term or temporary storage. The domestic refrigerators and freezers used for the purpose are usually small in sizes with ratings ranging from 1/20 to 1/2 tonne. The units are usually self-contained and hermetically sealed. Due to short-term storage the domestic refrigerator load is intermittent. The requirements of domestic refrigerator is that it should be simple in construction, automatic in action, nominal in initial cost, dependable, and without any necessity of expert inspection and repair. Non-irritant and non-toxic refrigerant should be used. Generally methylene chloride, Freon-12 and Freon-11 are used as the refrigerants.

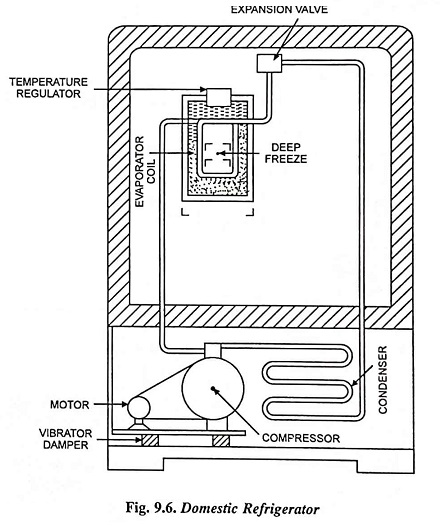

The common type of domestic refrigerator have a cabinet shaped with compressor motor-fan assembly, the condenser and receiver fitted in their basement. The expansion valve and evaporator coils are exposed in the storage cabinet with the pipings, carrying liquid refrigerant passing through the body. The heat of the bodies to be cooled is carried to the evaporator coils by means of air trapped in the cabinet. The refrigerator used may be the open compressor type; hermetically sealed compressor type or absorption type. Usually hermetically sealed type refrigerators are used. The main advantages are that the problem of gas leakage is minimized as no moving part extends through the sealed housing, it has relatively silent operation and it does not require any maintenance. In open type compressor, the motor drives the compressor using pulley and belt arrangement. This is employed in large commercial refrigerators.

Refrigeration is not only provided with double walled cabinet packed with materials having high thermal insulation such as fiberglass, cork or expanded rubber but also all round the inside of door flap soft rubber seal is used which makes the cabinet airtight. Also the door is provided with automatic closing mechanism—door hinges are provided in such a way that door flap when left in open position automatically comes to closing position due to gravity and as it approaches closing position it is attracted by the magnetic strip fitted behind the sealing rubber ring and thus the door is closed with snap action. All this is done to prevent leakage of atmospheric heat inside the refrigerator.

Main precaution to be taken is that very hot things should not be put in refrigerator, if it is done it will quickly evaporate the refrigerant in evaporator coils producing a large vapour pressure resulting in increase in the duty of the compressor and as such motor has to work for longer duration in order to bring down the temperature in the freezer compartment. It may damage the motor, which is short-time rated. Also moisture released from hot things will freeze around the freezer compartment which has to be defrosted.

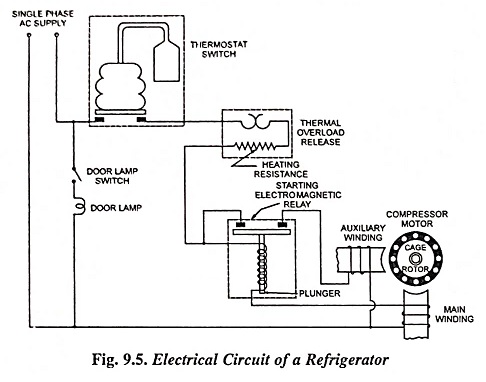

Electrical circuit of a refrigerator is shown in Fig. 9.5. Refrigerator is provided with a door push switch, which closes on opening of refrigerator and puts the lamp on. Capacitor-start single phase induction motor is used in open type refrigerators and split-phase single phase induction motor is used in sealed unit refrigerators. Electromagnetic relay is provided to connect auxiliary winding on the start and disconnect it when the motor picks up the speed. Thermal overload release is provided to protect the motor from damage against flow of overcurrent. Thermostat switch is provided to control the temperature inside the refrigerator. Temperature inside the refrigerator can be adjusted by means of temperature control screw. Greater the distance between contacts, greater will be the temperature inside the refrigerator and vice versa. To protect the motor against under voltage use of automatic voltage regulator is essential since in case of fall in applied voltage, motor will draw heavy current to develop the required torque and will become hot, thermal overload relay will, therefore, repeatedly disconnect and connect the motor to supply, eventually burning it out.

Domestic refrigerator employing vapour compression refrigeration system is shown in Fig. 9.6.

Trouble Shooting of Refrigerator:

Various troubles often found in a refrigerator are listed below.

| Symptoms | Causes |

| 1. Motor fails to start on giving supply. | (i) Blown fuses in the main switch. |

| (ii) Thermostat contacts open. | |

| (iii) Overload release open. | |

| (iv) Open circuit in the main winding. | |

| (v) Open circuit in the auxiliary winding. | |

| (vi) Grounded winding. | |

| (vii) Burnt or shorted winding. | |

| (viii) Excessive overload | |

| (ix) Worn-out or tight bearings. | |

| (x) Bent rotor shaft. | |

| 2. Motor runs slower than normal speed. | (i) Low voltage. |

| (ii) Overload. | |

| (iii) Shorted main winding. | |

| (iv) Defective electromagnetic relay. | |

| (v) Worn-out bearings. | |

| 3. Motor runs hot. | (i) Low voltage. |

| (ii) Overload. | |

| (iii) Shorted or grounding winding. | |

| (iv) Worn-out bearings. | |

| 4. Motors does not start and gives humming noise. | (i) Low voltage. |

| (ii) Overload. | |

| (iii) Open circuit in the auxiliary winding. | |

| (iv) Defective electromagnetic (starting) relay-contacts being not closed. | |

| 5. Motor runs with noise | (i) Shorted winding. |

| (ii) Improperly connected poles. | |

| (iii) Loose rotor bar. | |

| (iv) Worn-out bearings. | |

| (v) Too much end play. | |

| (vi) Foreign material in the rotor. | |

| 6. Motor keeps on running but | |

| (a) cooling is nil | (i) No refrigerant gas in the system (indicated by the unit, tubing and condenser being at ambient temperature). |

| (ii) Complete choking of capillary. | |

| (b) cooling is insufficient | (i) Less refrigerant gas in the system. |

| (ii) Partial choking of capillary. | |

| 7. Motor keeps on running even though it is very cold inside the refrigerator. | (i) Wrong setting of thermostat. |

| (ii) Defective thermostat—shorted wiring or sticking contacts. | |

| 8. Motor starts very frequently. | (i) Bad door seal. |

| (ii) Wrong setting of thermostat. | |

| 9. Motor operates normal with normal cooling in freezer but cooling in the rest portion is unsatisfactory. | (i) Bad door seal. |

| (ii) Opening of door too frequent. | |

| 10. Motor operates normal with good cooling but defrosting starts all of a sudden. Cooling again starts after some time | (i) Presence of moisture in the refrigerant cycle. |

| 11. Too much frosting around the freezer. | (i) High atmospheric humidity or steaming hot liquids stored. |