Electric Drives Interview Questions and Answers:

1. What is an electric drive ?

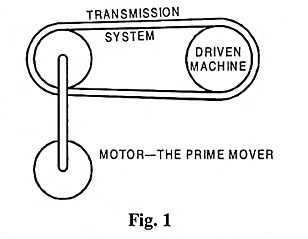

Ans. An electric drive is defined as a form of machine equipment designed to convert electrical energy into mechanical energy and provide electrical control of this process.

The basic elements of an electric drive are the electric motor, the transmission, and the electrical control system. Electric drives often include conversion equipment (frequency changers, rectifier units, motor-generator sets etc.) to attain smoother and more versatile control and make the motor operate on specific speed-torque characteristic.

2. Why electric drive is preferred over mechanical drive ?

Ans. Electric drive is preferred over mechanical drive because of its simplicity, cleanliness, easy and smooth control, flexibility in layout, compactness, reliability, long life, easy starting, low cost (initial as well as maintenance cost), facility for remote control etc. Modern electric drive with a system of automatic control fulfills several functions other than imparting motion to the working machine so as to carry out the production process involved in the most efficient manner. Using automatically controlled electric drives, machinery and production units may be operated with high productivity, ensuring at the same time high quality.

3. Enumerate the factors governing selection of electric motors.

Ans. The various factors that govern the selection of electric motor for a particular service are :

- Nature of electric supply available – dc or ac.

- Types of drives – individual, group or multimotor.

- Nature of load – active or passive.

- Electrical characteristics (operating, starting, speed control and braking).

- Mechanical considerations (Types of enclosures, types of bearings, types of transmission for drive, noise level etc.)

- Service capacity rating

- Appearance and

- Cost

4. Write classification of electric drives.

Ans. The various types of electric drives used in industry may be divided into three types : The group drive, the individual drive and multimotor drive.

5. What is group drive ?

Ans. Group drive, also sometimes called the line shaft drive, means a drive in which a single electric motor drives a line shaft by means of which an entire group of working machines may be operated.

6. What is individual drive ?

Ans. In an individual drive, a single motor is used to drive one individual machine. Example of such drives are single-spindle drilling machines, various types of electrical hand tools and simple types of metal working machine tools and mechanisms.

7. What is multimotor drive ?

Ans. Multimotor drive consists of several individual drives each of which serves to operate one of many working members or mechanisms in some production unit.

8. Why individual drive is preferred over group drive nowadays ?

Ans. Though the individual drive costs more than group drive, but each operator has complete control of his machine, which enables him to vary its speed if necessary and stop while not is use, thus eliminating no-load losses. The machines can be placed in any desired position and can be moved very easily. The motor and its control unit can be built as an integral part of the machine which results in good appearance, cleanliness and safety. For driving heavy machines such as for lifts, cranes, shapers, lathes etc. and for the purposes where constancy of speed and flexibility of control is required, such as in paper mills and textile industry, individual drive is essential.

For new factories individual drive is preferred, as it causes some saying in the cost of superstructure because of being much lighter and less expensive.

9. How does active torque differ from passive torque ?

Ans. Active torques are due to either gravitational force or deformation in elastic bodies whereas passive torques are due to friction or due to shear and deformation in inelastic bodies. Active torque continues to act in the same direction even after the direction of drive has been reversed while passive torque always opposes the motion, retarding the rotation of the driven machine.

10. What is meant by two-quadrant operation of a dc motor ?

Ans. The operation of an electric motor in forward motoring mode and in regenerating (or braking mode) is called the two-quadrant operation of the motor.

11. What factors govern selection of motor for a drive ?

Ans. For selection of reliable and efficient motor it is essential that the conditions of service are well known. It is not sufficient to simply specify the output power in kW and the speed but it is also necessary to know the following additional particulars :

- Torque at the shaft during running, starting and at different loads.

- Accelerating torque and braking torque.

- Switching frequency.

- Efficiency of motor at different loads.

- Other working requirements.

In studying the behavior of a motor selected for a particular driven unit, one of the first problems involved is to determine whether the speed-torque characteristic of the motor suits the requirements imposed by the speed-torque characteristic of the driven unit. Drive behavior during the transient period of a start-up, braking, or speed change-over also depends upon how the speed-torque characteristics of the motor and the driven unit vary with speed.

12. Why speed-torque (not torque-speed) characteristic curves are commonly used in utilization studies ?

Ans. In application engineering, it is usually the load torque which is known and the speed at which the motor can drive this load is unknown and is to be determined. Thus the torque is independent variable and speed is dependent variable. Consequently speed-torque characteristic curves with torque as abscissa are commonly used in utilization studies.

13. What will be the effect on direction of rotation of a dc motor if the supply terminals are reversed ?

Ans. No effect. Motor will rotate in the same direction, as before the reversal of the line terminals.

14. Why should a dc series motor not be run without load ?

Ans. On no load dc series motor would attain tremendously high speed and the motor may get damaged due to heavy centrifugal forces set up in rotating parts.

15. Why is series motor preferred for traction purposes ?

Ans. Because dc series motor develops large starting torque and slows down with the increase in load and so gets automatically relieved from heavy excessive load.

16. Why the dc motors are mostly gear motors ?

Ans. Because the low-speed motors are much more expensive than high-speed motors of the same kW output rating.

17. Why are induction motors called asynchronous motors ?

Ans. Because the rotor does not turn in synchronous with the rotating field developed by the stator current’s.

18. Is the maximum torque of a 3-phase induction motor dependent on the rotor resistance ?

Ans. No, it is independent of rotor resistance.

19. Why the power factor of an induction motor is low at starting ?

Ans. The rotor frequency and rotor reactance are high under starting conditions and, therefore, rotor currents lag the rotor emf by a large angle. This results in low power factor at starting.

20. The starting torque of a squirrel cage induction motor cannot be altered, when the applied voltage is constant, why ?

Ans. The starting torque of a squirrel cage induction motor cannot be increased as there is no provision for inserting resistance in the rotor circuit.

21. How will you improve the starting torque of a 3-phase induction motor ?

Ans. The starting torque of a 3-phase induction motor can be improved by inserting external resistance in each phase of the rotor circuit, which is possible only in case of wound rotor motors.

22. What are the main advantages of a cage motor ?

Ans. The main advantages of a cage motor are simple and rugged construction, low initial as well as maintenance cost, better efficiency and power factor, better cooling, more pull-out torque, greater maximum power output, nearly constant speed and simple starting arrangement.

23. What are the main disadvantages of a cage motor ?

Ans. The main drawbacks of a cage motor are low starting torque with large starting current and no possibility of a speed control.

24. What are the advantages and disadvantages of wound rotor over squirrel cage rotor in case of induction motor ?

Ans. In wound rotor external resistance can be inserted and, therefore,

- high starting torque can be obtained by inserting an external resistance of proper value in each phase of the rotor circuit and

- adjustable speed can be obtained simply by adding external resistors in the rotor circuit.

The drawback of wound rotor over squirrel cage rotor are initial and maintenance costs are more because wound rotor needs slip rings, brushes, short-circuiting devices etc.

25. Why in some induction motors double cage rotors are provided ?

Ans. In some induction motors double cage rotors are provided so as to get high starting torque with a low starting current as well as high operating efficiency. Such motors operate with the advantages of high-resistance rotor circuit during starting and low-resistance rotor circuit under running conditions.

26. State the advantages of squirrel cage induction motors over dc motors.

Ans. The important advantages of squirrel cage induction motors over dc motors are: (i) Ruggedness (ii) Lower maintenance (iii) Better reliability, (iv) Lower cost, weight, volume and interia, (v) Higher efficiency, (vi) Ability to operate satisfactorily with sharp voltage fluctuations and in dirty environment.

27. Why the V/f is kept constant while controlling the speed of a 3-phase induction motor ?

Ans. In order to maintain flux level constant.

28. How the power factor of a synchronous motor is changed keeping the shaft load undisturbed ?

Ans. By varying the field excitation.

29. For which type of loads, induction motor with voltage controller is suitable and why ?

Ans. Induction motor with voltage controller is suitable only for loads where the torque required drops off considerably with the drop in speed such as for driving fans because a large change in voltage is required for a relatively small change in speed and developed torque reduces greatly with the reduction in supply voltage.

30. How can the speed of a linear induction motor be controlled ?

Ans. By varying both frequency and voltage simultaneously.

31. Is the torque developed by a single phase induction motor at synchronous speed zero ?

Ans. No, it is negative.

32. Why single phase induction motors are usually set on rubber spring mounts ?

Ans. In a single phase induction motor, pulsating torque is developed as a direct consequence of the pulsating power in a single phase circuit.

33. Does a shaded-pole motor have large starting torque ?

Ans. No, it has very little starting torque.

34. What is a shaded-pole motor ?

Ans. Shaded-pole motor is a salient-pole, split-phase type, squirrel cage rotor single-phase induction motor provided with one or more auxiliary short-circuited stator windings displaced in magnetic position from the main winding.

35. State the applications of shaded-pole single phase induction motors.

Ans. Shaded-pole motor develops very little starting torque and, therefore, it is used only for small fans, electric clocks, hair dryers, time phonographs, advertising displays, toys, instruments and such other applications.

36. Why is the normal full-load slip of a single phase induction motor higher than that of a three-phase motor ?

Ans. The normal full-load slip of a single phase induction motor is higher than that of a 3-Φ motor, owing to development of backward rotating field. The power is to be delivered to the backward field from the power converted into mechanical power by the forward field.

37. What are the applications of electric drives ?

Ans. Squirrel cage induction motor is suitable for constant speed industrial drives of small power where speed control is not

required and where starting torque requirements are of medium or low value, such as for printing machinery, flour mills and other shaft drives of small power.

Wound rotor (or slip-ring) induction motors are used for loads requiring severe starting conditions or for loads requiring speed control such as for driving line shafts, lifts, pumps, generators, winding machines, cranes, hoists, elevators, compressors, small electric excavators, printing presses, turn tables, strokers, large ventilating fans, crushers etc.

Single phase induction motors find wide use in fans, refrigerators, air conditioners, vacuum cleaners, washing machines, other kitchen equipment, record players, small farming appliances etc.

38. State whether repulsion motor has series speed-torque characteristics, or shunt speed-torque characteristics.

Ans. Series speed-torque characteristics.

39. What is a stepper motor ?

Ans. A motor which turns in discrete movement is called a stepper motor.

40. For stopping the motor, the line switch should always be opened rather than throwing back the starting arm. Why ?

Ans. If the starter arm is thrown back the field circuit is broken at the last contact button and owing to inductive nature of field, this will cause a hot arc and burn the contact.

41. Why do you require starters for starting a 3-phase induction motor ?

Ans. Starter is required to limit the initial rush of current to a predetermined value at the starting instant.

42. Which is the cheapest method of starting a 3-phase induction motor ?

Ans. Direct-on-line (D-O-L) starting.

43. What type of protection is provided in the starters meant for 3-phase induction motors ?

Ans. Overload and undervoltage protection.

44. Which method we must adopt to control the speed of a dc shunt motor above the base speed ?

Ans. Field control method.

45. While controlling the speed of a dc shunt motor what should be done to achieve a constant torque drive ?

Ans. Applied voltage should be maintained constant so as to maintain field strength constant.

46. If the number of poles on a motor is increased to lower the speed, how will the power factor be affected

Ans. Power factor will be reduced.

47. How is speed control affected in a 3-phase ac series commutator motor ?

Ans. In a 3-phase ac series commutator motor, the speed control is affected by moving all brushes simultaneously round the commutator by means of a hand-wheel.

48. How is speed control affected in a 3-phase ac shunt commutator motor ?

Ans. In a 3-phase ac shunt commutator motor, the speed is adjusted by changing the tapping points on a transformer inserted between the supply mains and the brushes, which are in fixed position.

49. How speed variation is affected in a repulsion motor ?

Ans. Speed variation in a repulsion motor is affected either by varying the impressed voltage or by changing the position of brushes.

50. What is meant by plugging ?

Ans. Plugging means stopping of an electric motor by instantaneously reversing its torque till it stops.

51. How plugging of a dc motor is done ?

Ans. Plugging is obtained in a dc motor by reversing the supply terminals to the armature of the motor.

52. What is the most economical method of electric braking ?

Ans. Regenerative braking.

53. Electric braking is accomplished in an induction motor by interchanging two stator terminals. Name the method.

Ans. Plugging or counter-current braking.

54. When it is required to control the induction motor speed during deceleration what kind of braking is preferable to employ ?

Ans. DC dynamic braking is highly suitable for controlling the speed of an induction motor during deceleration by controlling the dc excitation.

55. How is choice of drive governed ?

Ans. Choice of drive is governed by the speed of driving and driven machines, convenience, space available, including clutching arrangement required and cost.

56. What is meant by “rating of motor” ?

Ans. A name plate fixed to the outside frame of an electrical machine records the data pertaining to its rating. A machine rating specifies the voltage, current, speed, excitation, power factor, efficiency, power output etc.

The rating of a machine should give all information necessary so that, if the machine is operated within the limits of all factors specified in its rating, the machine will operate satisfactorily and safely and will give reasonable length of service. Therefore, the rating of a machine must give the necessary information to safeguard the application of the machine from conditions of operation which (i) would result in unsafe mechanical or electrical strains upon any part of its structure or (ii) would result in excessive deterioration of the mechanical or electrical characteristics of the materials of which the machine is constructed, To give this information, the rating of an electric machine should include the output, voltage, speed, and any other information that may necessary for the proper operation of the machine.

57. On what factors does the rate of rise of temperature depend ?

Ans. The rate of temperature rise depends upon (i) amount of heat produced and (ii) the amount of heat dissipated per °C rise of the surface of the machine.

58. Why the cooling time constant of a rotating machine is usually larger than its heating time constant ?

Ans. The cooling time constant of a rotating machine is usually larger than its heating time constant owing to poor ventilation conditions when the machine cools.

59. What is meant by load equalization ?

Ans. The process of smoothing out of fluctuations in load is known as load equalization.

60. How is load equalization achieved ?

Ans. The most common method of load equalization is by use of flywheel. During the light load period the flywheel accelerates and stores the excessive energy drawn from the supply and during peak load period the flywheel decelerates and supplies some of its stored energy to the load in addition to the energy supplied from the supply. Thus the load demand is reduced.