Electrostatic Precipitator (ESP) – Construction and Working Principle:

Electrostatic Precipitator is located between the boiler and the chimney, it extracts the fly ash from the flue gases and thus prevents the fly ash from entering the atmosphere. Electrodes are used to attract the fly ash when the flue gas coming out of the boiler is passed through the ESP.

Working Principle of Electrostatic Precipitator:

In this, the dust particles are separated from flue gases by electrostatic attraction. It has two steps of operation. One is charging of dust particles and other is to collect dust particles. In charging section, the flue gas is ionized and in collecting section dust particles are collected on the collector electrodes.

Construction:

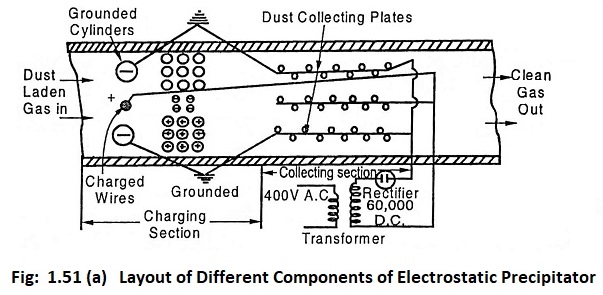

The Fig. 1.51(a) shows the general layout of an electrostatic precipitator. In a single stage electrostatic precipitator, a pair of electrodes serve both the particle charging and collecting function and in two stage electrostatic precipitator, two pair of electrodes are used – one for charging and other for collecting. The discharge electrode is connected to the high tension power supply. The collector electrode is earthed. An electro static field is setup in between two electrodes. A weight is kept to align the electrode along the cylinder axis.

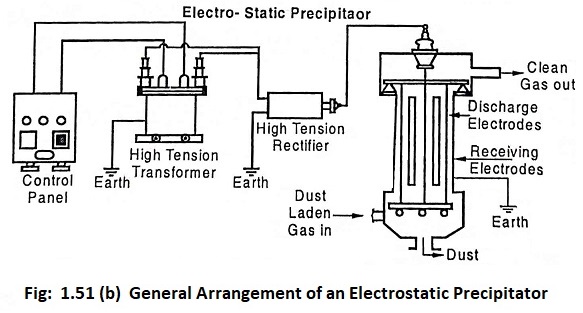

In Fig.1.51(b) the flue gas is passing through the bottom of the precipitator. When gas moves upward, the dust particles and the flue gases are ionized by the high voltage (30,000 to 60,000 volts) applied between the conductors. The electro static field exerts a force on the dust particles and they are driven towards the grounded plates. The dust particles are deposited on the collector electrodes and they are removed by rapping (Shaking motion given to electrode) by means of cams. The dust particles are collected in hopper and removed periodically.

Advantages:

- Best suitable for high dust laded gases.

- Very small particles, mist and fly ashes enter the atmosphere.

- The dust is collected in dry form and can be removed in dry or wet form.

- Maintenance cost is less compared to other types.

- It has efficiency of 99.5%.

Disadvantages:

- Power requirement is high for charging the dust particles and fly ash.

- Space requirement is more than wet system.

- Efficiency varies inversely with the gas velocity

- The dust carried with the gases increases with an increase of gas velocity. Electrical equipment’s are needed for conversion of low voltage to high voltage. This increases the capital cost.

Even though its cost is more, it is frequently used with pulverised coal firing system because of its effectiveness.