Fabrication of Integrated Circuits Articles:

Integrated Circuit Definition: Integrated Circuit Definition referred as microelectronics, is the result of continued improvements in the characteristics and miniaturizations employed in solid state devices and components. So we can call integrated electronics as logical extension of silicon device technology. Today integrated … (Read More)

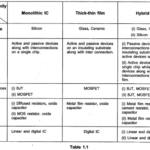

Integrated Circuits Classification: Depending upon the functional utility, the Integrated Circuits Classification are classified as linear ICs and digital ICs. From the point of view of structural considerations, ICs can be divided as monolithic ICs, thick-thin film ICs and hybrid ICs. … (Read More)

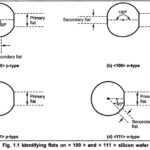

Basic Planar Process in IC Fabrication: The Basic Planar Process in IC Fabrication are as listed below. Crystal growth and wafer preparation, Epitaxial growth, Oxidation, Lithography, Reactive plasma etching, Diffusion, Ion implantation, Metallization, Assembly techniques and packaging Let us study each process in detail one by one. Crystal Growth and Wafer Preparation: In … (Read More)

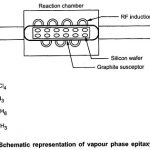

Basic Planar Process in IC Fabrication: The Basic Planar Process in IC Fabrication are as listed below. Crystal growth and wafer preparation, Epitaxial growth, Oxidation, Lithography, Reactive plasma etching, Diffusion, Ion implantation, Metallization, Assembly techniques and packaging Let us study each process in detail one by one. Crystal Growth and Wafer Preparation: In … (Read More)Vapour Phase Epitaxy Process: In chemical vapour deposition (CVD), the film is formed on the surface of the substrate by thermal decomposition and or the reaction of various gaseous compounds. As in CVD, the epitaxial layer is formed from the gaseous … (Read More)

Molecular Beam Epitaxy Process: The molecular beam epitaxy (MBE) is based on evaporation. In MBE, the film is evaporated and deposited one layer at a time. In the process, no chemical reactions are considered. Instead of that the evaporation of silicon … (Read More)

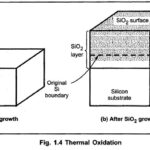

Oxidation in IC Fabrication: Oxidation in IC Fabrication is very important process. In one line, oxidation can be explained as the production of SiO2 using the thermal growth technique. Some of the important uses of SiO2 are as follows. In bipolar and MOS … (Read More)

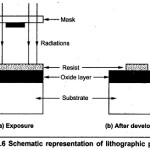

Lithography Process in IC Fabrication: Lithography Process is used to produce a multiple image on the resists which covers the wafer. A Lithography Process in IC Fabrication can be realised with the help of three sub processes given by, Deposit of the … (Read More)

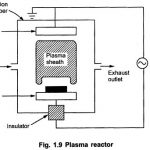

Reactive Plasma Etching: The reactive plasma is the discharge in which gases ionized producing chemically active species, oxidizers, reagents. The plasma is reactive in both gaseous and solid phase, hence the name is Reactive Plasma. These plasmas are used to remove … (Read More)

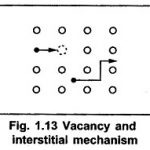

Diffusion Process in IC Fabrication: Diffusion is the oldest technique used to add impurity into the Substrate. The main aim of the Diffusion Process in IC Fabrication is to change the Conductivity of silicon substrate over a depth. The Diffusion Process in … (Read More)

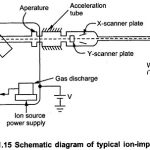

Ion Implantation Process in IC Fabrication: As we know, the conductivity of the semiconductor increases when small impurity is added to it. The process of adding impurity is called doping while the impurity to be added is called dopant. So ion … (Read More)

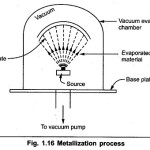

Metallization Process | Types of Metallization | Applications: Metallization Process in which a thin layer of metal is formed which is used to make interconnections between the components on the chip as well as interconnections between the components and the outside … (Read More)

IC Packaging Process | IC Package Types: After completing all the fabrication processes, several chips are ready on a wafer. Each of the chip is nothing but a complete circuit. Now the next step is to separate out these chips and … (Read More)

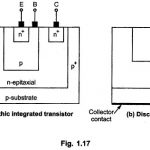

Fabrication of Monolithic IC: The cross-sectional view of an Fabrication of Monolithic IC and discrete planar transistor are as shown in the Fig. 1.17 (a) and (b) respectively. The main difference between Fabrication of Monolithic IC and discrete planar transistor is that … (Read More)

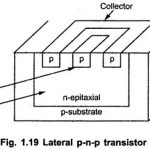

Fabrication of PNP Transistor in Integrated Circuit: There are different ways of Fabrication of PNP Transistor in Integrated Circuit. The important means of integrating PNP Transistor are Vertical PNP transistor, Lateral PNP transistor and Triple Diffused PNP transistor. Vertical PNP transistor: In Vertical PNP … (Read More)

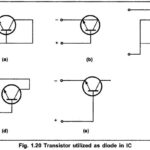

Monolithic Diodes: The fabrication of diode is very straight forward. Generally any two terminals of the transistor are connected together to form one of the electrodes while the remaining terminal can be considered as remaining electrode of a … (Read More)

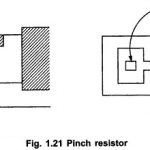

Integrated Resistor: In Integrated Resistor circuit design, the importance is given to the maximum usage of transistors. For example digital CMOS, nMOS and GaAs circuits are fabricated entirely with transistors and diodes. The Integrated Resistor are grouped into two groups ; one … (Read More)

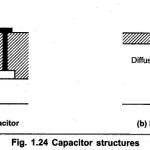

Parallel Plate Capacitor in IC Fabrication: The Parallel Plate Capacitor in IC Fabrication structures are as shown in the Fig. 1.24. In most widely used parallel plate capacitor type shown in Fig. 1.24 (a), the two polysilicon plates are seperated by silicon … (Read More)

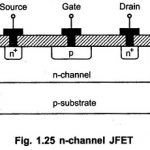

Types of Field Effect Transistor: In general, Three Types of Field Effect Transistor are namely, Junction field effect transistor (JFET) Metal oxide semiconductor field effect transistor (MOSFET) Complementary Metal Oxide Semiconductor (CMOS) Junction field effect transistor (JFET): The basic processes used for the fabrication of JFET … (Read More)