Forced Cooling in Transformer:

Forced Cooling in Transformer – For transformer sizes beyond 5 MVA additional cooling would be needed which is achieved by supplementing the tank surface by a separate radiator in which oil is circulated by means of a pump.

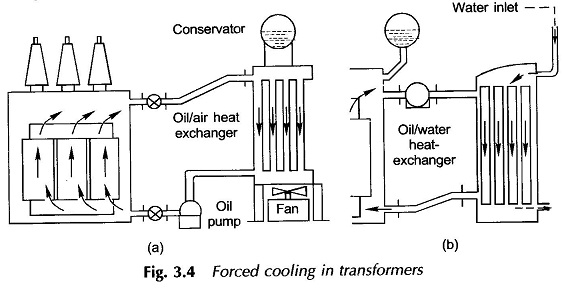

For better cooling oil-to-air heat exchanger unit is provided as shown in Fig. 3.4(a).

For very large size transformers cooling is further strengthened by means of oil-to-water heat exchanger as shown in Fig. 3.4(b).

As already pointed out, ducts are provided in core and windings for effective heat removal by oil. Vertical flow is more effective compared to horizontal flow but for pancake coils some of the ducts will have to be horizontal.

The problem of cooling in transformers is more acute than in electric machines because the rotating member in a machine causes forced air draft which can be suitably directed to flow over the machine part for efficient heat removal.