High Voltage Test on Insulators:

The High Voltage Test on Insulators that are normally conducted are usually subdivided as

-

Type tests and

-

The routine tests.

Type tests are intended to prove or check the design features and the quality. The routine tests are intended to check the quality of the individual test piece. Type tests are done on samples when new designs or design changes are introduced, whereas the routine tests are done to ensure the reliability of the individual test objects and quality and consistency of the materials used in their manufacture.

High Voltage Test on Insulators

-

Power frequency tests, and

-

Impulse tests.

All the insulators are tested for both categories of test.

Power Frequency test:

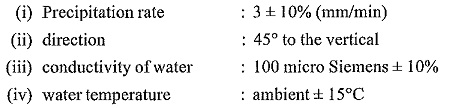

(a) Dry and Wet Flashover Tests: In these tests the a.c. voltage of power frequency is applied across the insulators and increased at a uniform rate of about 2 per cent per second of 75% of the estimated test voltage, to such a value that a breakdown occurs along the surface of the insulator. If the test is conducted under normal conditions without any rain or precipitation, it is called “dry flashover test“. If the test is done under conditions of rain, it is called “wet flashover test“. In general, wet tests are not intended to reproduce the actual operating conditions, but only to provide a criterion based on experience that a satisfactory service operation will be obtained. The test object is subjected to a spray of water of given conductivity by means of nozzles. The spray is arranged such that the water drops fall approximately at an inclination of 45° to the vertical. The test object is sprayed for at least one minute before the voltage application, and the spray is continued during the voltage application. The characteristics of the spray are

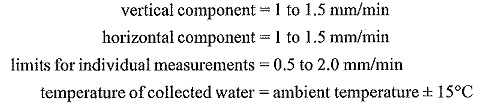

The International Electrotechnical Commission (IEC) in its document (No. 42 of 1972) has revised the test procedure and precipitation conditions as follows.

Average precipitation rate:

and the conductivity of water corrected to 20°C = 100 ± 15 micro Siemens Specifications are being modified for application of 15 positive and 15 negative impulses. Two in each set are allowed to flashover. If more than two flashovers occur in each set, then the insulator is deemed to have failed the test. This procedure is satisfactorily equivalent to the one mentioned above.

(b) Wet and Dry Withstand Tests (One Minute): In these tests, the voltage specified in the relevant specification is applied under dry or wet conditions for a period of one minute with an insulator mounted as in service conditions. the testpiece should withstand the specified voltage.

Impulse Tests:

Impulse Withstand Voltage Test: This test is done by applying standard, impulse voltage of specified value under dry conditions with both positive and negative polarities of the wave. If five consecutive waves do not cause a flashover or puncture, the insulator is deemed to have passed the test. If two applications cause flashover, the object is deemed to have failed. If there is only one failure, additional ten applications of the voltage wave are made. If the test Object has withstood the subsequent applications, it is said to have passed the test.

Impulse Flashover Test: The test is done as above with the specified Usually, the probability of failure is determined for 40% and 60% failure values or 20% and 80% failure values, since it is difficult to adjust the test voltage for the exact 50% flashover values. The average value of the upper and the lower limits is taken. The insulator surface should not be damaged by these tests, but slight marking on its surface or chipping off of the cement is allowed.

Pollution Testing: Because of the problem of pollution of outdoor electrical insulation and consequent problems of the maintenance of electrical power systems, pollution testing is gaining importance. The normal types of pollution are

- dust, micro-organisms, bird secretions, flies, etc.,

- industrial pollution like smoke, petroleum vapours, dust, and other deposits,

- coastal pollution in which corrosive, and hygroscopic salt layers are deposited on the insulator surfaces,

- desert pollution in which sand storms cause deposition of sand and dust layers,

- ice and fog deposits at high altitudes and in polar countries.

These pollution cause corrosion, non-uniform gradients along the insulator strings and surface of insulators and also cause deterioration of the material. Also, pollution causes partial discharges and radio interference. Hence, pollution testing is important for extra High Voltage Test on Insulators in voltage systems.

At present there is no standard pollution test available. The popular test that is normally done is the salt fog test. In this test, the maximum normal withstand voltage is applied on the insulator and then artificial salt fog is created around the insulator by jets of salt water and compressed air. If the flashover occurs within one hour, the test is repeated with fog of lower salinity, otherwise, with a fog to higher salinity. The maximum salinity at which the insulator withstands, three out of four tests without flashover, is taken as the representative figure. Much work is yet to be done to standardize the test procedures.