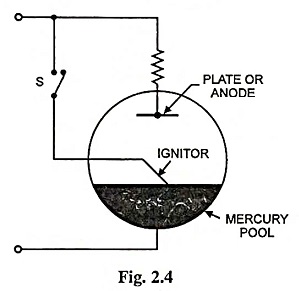

Ignitron Working Principle:

Ignitron is a gaseous tube and consists of carbon anode, boron carbide ignitor tube and mercury pool cathode. It is a cold cathode tube and does not have any heating element or grid control as in thyratron. Therefore, electrons are to be made available before the tube starts conducting. This is achieved by the ignitor which remains dipped in the mercury pool but being made of boron carbide does not get wet and, therefore, gives high resistance, say 10 to 500 Ω, between the mercury pool and ignitor. On closing of switch S full voltage is impressed between ignitor and mercury pool. This causes intense electric field which pulls out electrons from mercury pool to start with.

The electrons of the arc ionize the mercury vapours if the ignitor current is of the magnitude between 20 and 40 amperes. Positive ions thus released are attracted towards cathode mercury pool and momentum of these mercury ions releases large number of electrons from the cathode pool by secondary emission.

These electrons are attracted towards the carbon anode. Now resistance of main path of the current is very low as compared to that of ignitor path and, therefore, ignitor current stops. This process is to be repeated every time anode becomes positive in ac voltage cycle.

Ignitrons can handle current from 40 to 10,000 A. It may also be noted that electronic current flow from ignitor to cathode, spoils the ignitor and, therefore, should not be permitted.

The power output can be controlled by timing the firing by means of the ignitor, usually by shifting the phase of the pulse to the ignitron.

The single units may be connected in 3-phase, 6-phase, or 12-phase. In smaller ratings, sealed-in glass tubes are used; in the intermediate ratings, sealed-in water-cooled metal tanks are used. In the larger power units, pumped all steel water-cooled tanks are used.