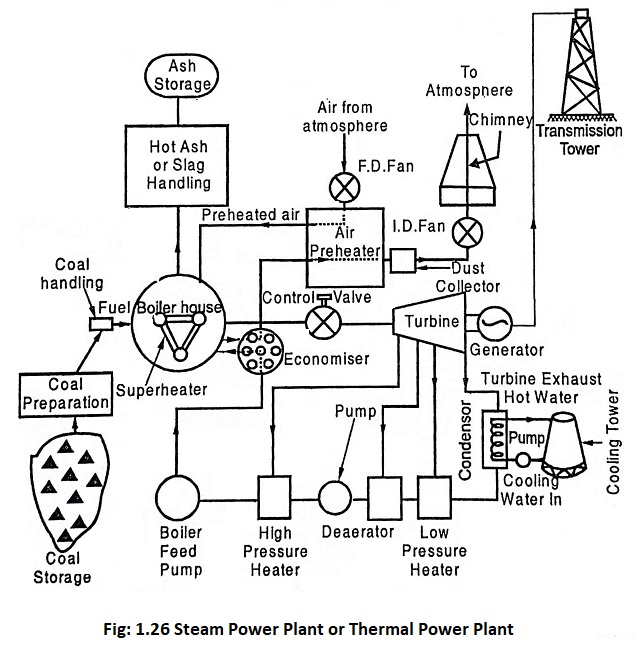

Layout of Modern Coal Power Plant or Steam Power Plant:

In Coal Power Plant or Steam Power Plant, the water is converted into steam and the steam expanded in a turbine to produce kinetic energy which is converted into mechanical energy.

The Coal Power Plant or Steam Power Plant has four major circuits by which the layout can be studied in detail. These are

- Coal and ash circuit

- Air and flue gas circuit

- Feed water and steam circuit

- Cooling water circuit

1. Coal and ash Circuit:

This circuit consists of coal delivery, preparation of coal, handling of coal to the boiler furnace, ash handling and ash storage.

The coal which is received from the mines are stored in coal storage. This raw coal is sized by crushers and then this prepared coal is transferred to the boilers.

In the boiler, the coal is burnt and converted into ash. This ash is usually quenched to reduce the temperature, corrosion and dust content. Then it is stored at ash storage.

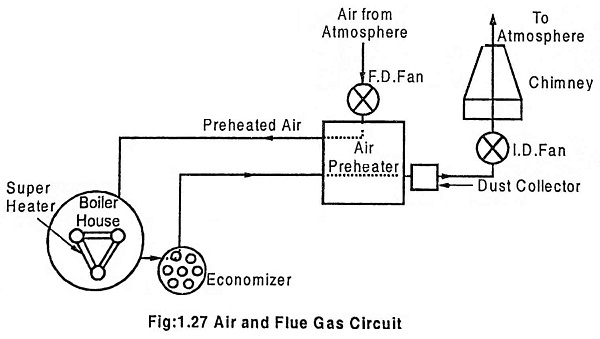

2. Air and Flue gas circuit:

This circuit consists of forced draught fan, air-preheater, boiler furnace, super heater, economizer, dust collector, induced draught (ID) fan and chimney.

The air from the atmosphere is forced into the circuit by a forced draught fan. This air is preheated in the air preheater by flue gases. This pre heated air is supplied to the furnace where this air is converted into flue gases. This flue gases pass over the boiler tubes by which the water is converted into steam. Then this flue gas is passed to the super heater where the steam is converted into super heated steam. Then it is passed to the economizer to heat the feed water and to the air preheater. The dust in the flue gases are collected by the dust collector and then left to atmosphere through chimney.

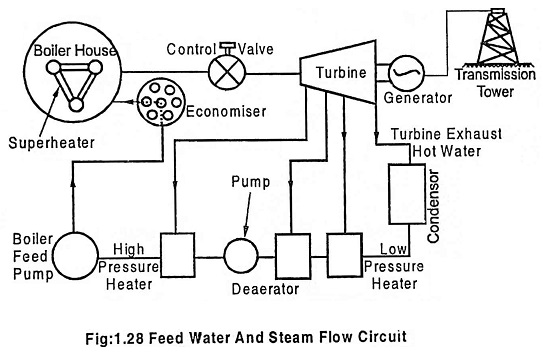

3. Feed water and steam flow circuit:

This circuit consists of feed pump, economizer, boiler drum super heater, turbine and condenser. From the hot well, the feed water is pumped to the economizer where the water is preheated by the flue gases. This preheated water is supplied to the boiler drum. In the boiler drum, the pre heated water is converted into steam by burning of coal. The steam raised in boiler is passed through the super heater where the steam is converted into super heated steam. The super heated steam is expanded in turbine which is coupled with generator. The expanded steam is then passed through the condenser in which the steam is converted into water and this water is recirculated.

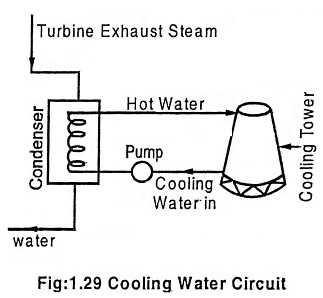

4. Cooling Water Circuit:

This circuit consists of a pump, condenser and cooling tower. In the condenser, cold water is circulated to condense the steam in to water. The steam is condensed by loosing its latent heat to the circulating cold water. By this, the circulating water is heated. This hot water is cooled at the cooling tower, where the water is sprayed in the form of droplet through nozzles. The cold air enters the cooling tower from the bottom which cools the sprayed hot water. The cooled water is collected in the cooling pond and the same is re circulated again and again. To compensate the water lost due to vapourisation, the make up water is added to the pond by means of a pump.