Methods of Ventilation and Cooling of Electrical Machines:

It is necessary to provide suitable ventilation and cooling of electrical machines so that the temperature rise at any part of the machine does not exceed the permissible limit governed by the type of insulation employed in the construction. The cooling of electrical machine by means of an air stream is called ventilation of the machine.

The circulation of air in the machine can be arranged by the use of a built-in fan or fan with a separate drive. Either a centrifugal type fan or an axial type fan is employed for rotating electrical machines. A centrifugal fan forces air from the centre to flow outwards and operates the same way irrespective of the direction of rotation of the machine. An axial or propeller type fan moves the air in the opposite direction when the direction of rotation of the machine reverses.

According to IS : 4722-1968, the cooling system for rotating electrical machines are classified into three types depending up the origin of cooling.

1. Natural Cooling

The machine is cooled by air movements in the machine due to its rotation or due to temperature difference between inside parts and the outside temperature of the air. The machine thus is cooled without the use of a fan, by the movement of air and radiation. This method of cooling is employed only in small fractional kW machines with rating within several hundred watts, since the condition of cooling are comparatively favourable.

2. Self Cooling

The machine is cooled by air, blown by fan integrally built with the motor or mounted on the shaft.

3. Separate Cooling

The machine is cooled either by a fan not driven by its shaft, or it is cooled by a cooling medium other than air put into motion by means not belonging to machine.

According to the manner of ventilation and cooling of electrical machines are classified as

1. Open-Circuit Ventilation

The heat is given up directly to the cooling air flowing through the machine which is being continuously replaced. The open-circuit ventilation can be further divided into two types in accordance with how the air is brought into the machine.

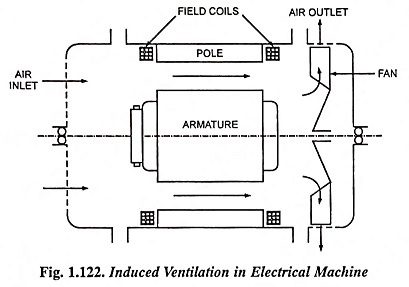

(a) Induced Ventilation: Induced ventilation method used in an electrical machine is illustrated in Fig. 1.122. In this arrangement, a fan produces a reduced pressure of air inside the machine and air from outside is sucked into the machine owing to the atmospheric pressure. The air is circulated through the machine and then pushed out by the fan into the atmosphere. The fan is normally arranged inside the machine, as illustrated in the figure. The fan can be provided externally also.

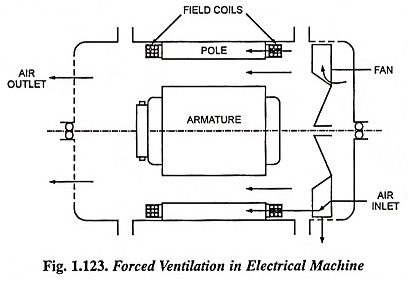

(b) Forced Ventilation: In this method of ventilation, illustrated in Fig. 1.123, the fan sucks the air from outside and forces it into the machine and finally pushed out into the atmosphere. For forced ventilation, the pressure of air inside the machine is greater than the atmospheric pressure outside. The fan may be arranged internally, as illustrated in the figure or externally,

2. Closed Circuit Ventilation

In this system of cooling, heat is transferred to the cooling medium such as air or hydrogen through an intermediate cooling medium circulating in a closed circuit between the interior of the machine and the cooling device, e.g., a water cooler can be used to cool the cooling medium such as air.

For increasing the surface of contact for cooler, stator and rotor cores of electrical machines are provided with ducts. These ducts may be radial or axial type depending on the direction of air flow through them.

3. Surface Ventilation

The heat is transferred from inside of the machine, by cooling medium, to the external surface of a totally enclosed machine. The external surface is being cooled by natural means or mainly by air blown by fan.