MHD Power Plant Working Principle:

MHD Power Plant or Magneto Hydro Dynamic is concerned with the flow of a conducting fluid in the presence of magnetic and electric field. The fluid may be gas at elevated temperature or liquid like sodium (or) potassium.

MHD Power Cycle Principles:

Faraday’s law of electromagnetic induction states that a changing magnetic field is induced in an electric field in any conductor located in it. The magneto hydro dynamic (MHD) generator is based on the Faraday’s law of electromagnetic induction.

This electric field while acting on the free charges in the conductor causes a current to flow. In case of conventional electric generator, the conductor crosses the line of the magnetic field and a voltage is induced. Similarly, in a magnetic hydrodynamic generator, when an ionised gas flows across the lines of magnetic field, a voltage is induced. The ionised gas acts like an electrical conductor.

Magneto hydro dynamic generator is an efficient heat engine which directly converts thermal energy into electricity. A MHD generator uses a suitable working fluid which is electrically conducting. The working fluid is a partially ionised gas. The concepts of MHD generation depends much more on the conductivity of the gas.

The conductivity of the gas is a function of temperature.

Gases become conducting when their atoms of molecules are stripped off one (or) more electrons thermally, electrically (or) by using radiations.

However, extremely high temperatures are necessary to achieve thermal ionization of the products of combustion of fossil fuel (or) inert gases. Reasonable value of electrical conductivity is obtained at temperature around 2000 to 3000 K, when the gases are soaked with additives of easily ionising materials like alkali metals. This type of power generation will reduce environmental pollution considerably.

Normally, the initial cost of MHD power plant is slightly higher than that of conventional thermal power station but it will be tolerated by its higher efficiency and improved cycle of operation.

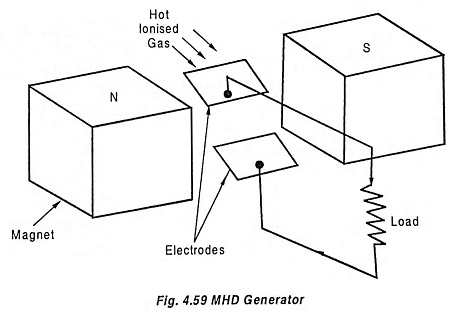

The important components of MHD generator are shown here.

The hot ionized gas passes between the poles of an electro-magnet. It induces a potential difference between a pair of electrodes which are set at right angles of magnetic field. During this, a current starts flowing in the resistive load connected between electrodes.

The ionised gas has high temperature and pressure and after passing through MHD generator, it is passed through a generator where energy is added to it and it is then recirculated in the MHD generator. This system is simple one. This system has large power and temperature handling capacity. It has high-reliability since the system does not have any moving parts.

The MHD power plants can operate as base load unit, peak load unit (or) semi peak load unit. It can operate along with a large load variations without significant loss in efficiency.

Types of MHD generators:

- Open cycle MHD

- Closed cycle MHD

- Closed cycle MHD with liquid metal

Open cycle MHD:

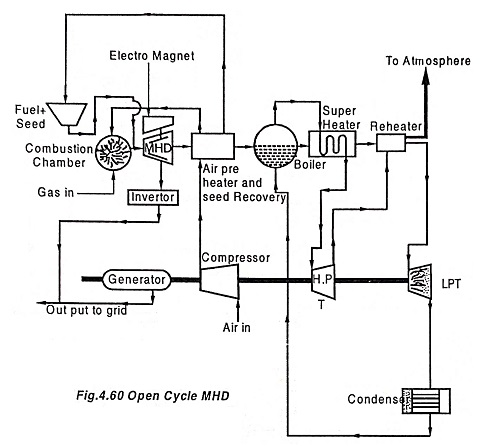

The open cycle MHD generator is shown in Fig.4.60. The gaseous fuel is burnt in the presence of high pressure air (5 bar) in the combustion chamber. The high temperature gas is passed through MHD after seeding.

To achieve the conductivity of the copper, the plasma must be heated to very high temperature. The MHD generator can operate at ionization levels well below this temperature and the ionization can be simulated at lower temperature by seeding the gas with small quantities of alkali metals such as cesium (or) potassium.

The interaction between magnetic field and plasma gas produces electricity.

The hot gas is utilized to generate steam. The steam generated is used in conventional power plants. The power from the generator is coupled to steam turbine and power from MHD after converting from DC to AC is fed to the grid. The efficiency of open cycle MHD is between 50% to 60%.

Closed cycle MHD:

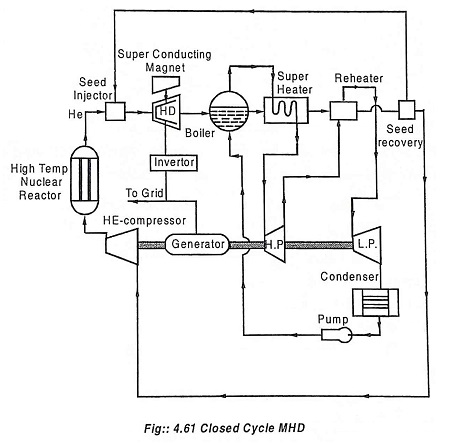

The line diagram of closed cycle MIND is shown in Fig.4.61. In closed cycle MHD, the working fluid used are rare gases. The rare gas is heated by the gas cooled nuclear reactor. The working principle of closed cycle MHD is similar to open cycle MHD except that the working fluid is recirculated again and again instead of exhausting to the atmosphere. The most suitable working fluid gases are noble gases like helium, neon, argon, krypton and xenon because they have low electron affinity. Neon is best suitable but helium is used mostly since it is available readily. With the use of noble gas, calcium is used as seed material which is most economical than potassium.

Closed Cycle MHD with Liquid metal:

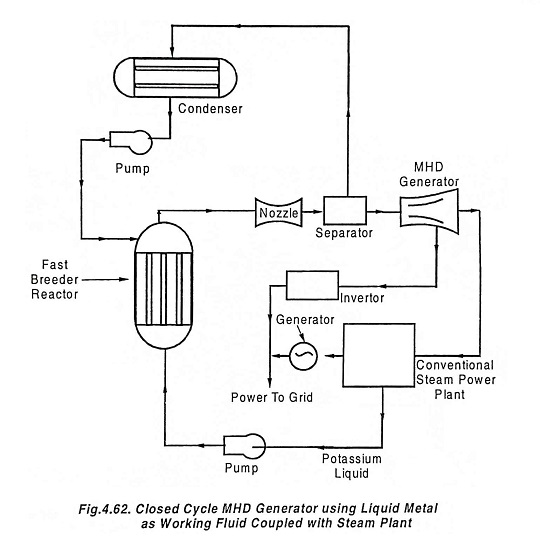

In this, liquid metal is used instead of gas as they have high electrical conductivity (i.e about 106 times that of plasma). The liquid metal MHD cycle is shown in Fig.4.62.

The liquid metal generator is linked with breeder reactor which has thermal flux source. The only difficulty in this system is that the production of liquid flow with high kinetic energy from a thermal power source. Before passing thorough MHD, the liquid potassium from the breeder reactor at high temperature is passed through a nozzle to increase velocity of liquid metal. The vapors formed due to nozzle action are separated in the separator and condensed and then pumped back to the reactor. The heat of the liquid potassium from MHD is utilized in conventional steam power plant.