Negative Booster in Electric Traction:

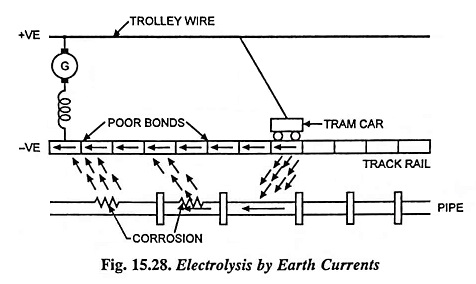

In case of dc traction system, return current flows through the rails, to the substations. So due to this current flow through rails some voltage drop exists along the track. Due to potential difference along the track some of the return currents leak out to the earth and follow low resistance paths provided by water pipes, gas mains, cable sheaths etc. as shown in Fig. 15.28. These leakage currents cause electrolytic corrosion to occur at places where the current leaves the pipes as they carry the metal of the pipe (acting as anode) to the electrolytic solution (moisture and salts in the surrounding soil).

The statutory regulations, according to which the voltage drop in the rails is limited to 7 volts and the voltage between any pipe and the rails is limited to 1 volt positive and 3 volts negative, are to minimize the corrosion of pipes and cable sheaths adjacent to track.

The voltage drop in the track rails is maintained within the limit of 7 volts by adopting any one of the following methods.

- By making return path of very low resistance, which may be achieved by providing good bonds or by employing insulated negative feeders.

- By discouraging the entry of current into the pipes by inserting occasional insulating joints.

- By using negative booster in electric traction.

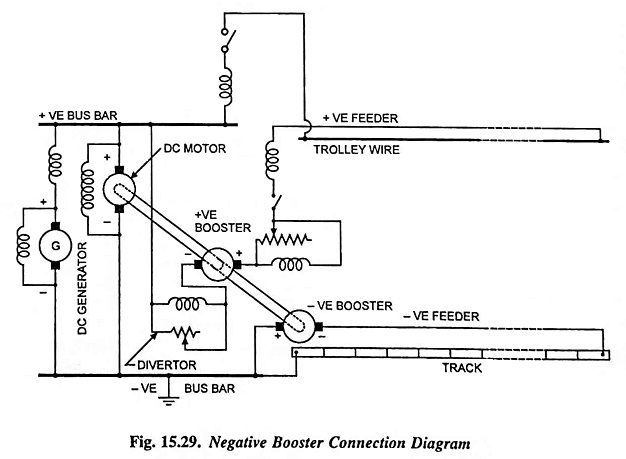

As shown in Fig. 15.29, the negative bus-bar is connected to the track rail through negative feeder and the positive bus-bar is connected to the trolley wire near the generating stations.

There are two boosters, one is positive booster which adds voltage to the line and the other is the negative booster in electric traction which lowers the potential of the point to which it is connected. Both the boosters are mechanically coupled together and driven by a dc motor. Negative booster is separately excited dc generator whose armature is connected with negative busbar at the far end of the track through negative feeder.

Field of negative booster in electric traction is connected in series with positive feeder supplying the corresponding sections of the trolley wire. The boost on the feeder is adjusted by means of a diverter rheostat connected in parallel with the field winding.

Sometimes a positive booster is also connected to the + ve side in addition to – ve booster on – ve side in order to compensate the voltage drop in trolley wire. Positive booster is a self excited series generator which is connected across the + ve busbar and at the far end of trolley wire in series with the field of the negative booster in electric traction.