Neon Tube – Working Principle, Installation and Faults:

The popularity of high voltage neon lighting arose almost entirely from its use in advertising, for signs, or in the decorative treatment of buildings, but later the lighting field became important. The neon tube, which is used in varying lengths up to about 9 metres, may be bent into almost any desired shape dining manufacture. It consists of a length of glass tubing containing two electrodes, normally cylindrical in shape, of iron, steel, or copper.

The true neon tube contains neon, but the term is now used also for tubes with fillings of other rare gases. By varying the composition of glass and adding different substances to neon gas different colours such as orange, red, yellow, green etc. are obtained. The diameters of the tube vary, and common sizes of 10, 15, 20 and 30 mm carry currents of 25, 35, 60 and 150 mA respectively. Voltage required may vary from 300 V to 1,000 V per metre of tube length and for starting the discharge a striking voltage, about 1 1/2 times this value is required. Such voltage is obtained by making use of a step-up transformer having a high leakage reactance so that it gives a drooping characteristic. The usual operating voltage is 6,000 volts.

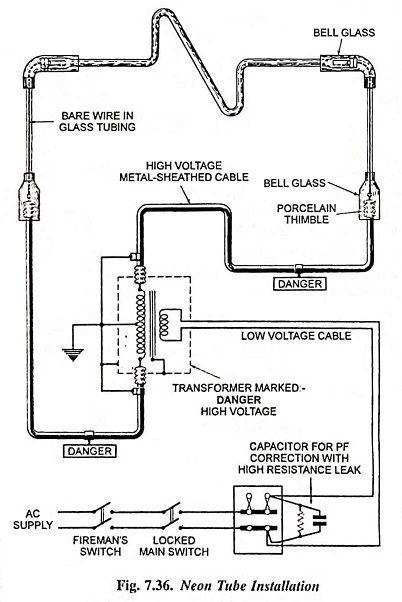

The tubes are mounted either on a wooden frame or a metal base. These are matched with step-up transformers by connecting suitable tappings for the rated current. Connections between letters are made by nickel wires, the glass tubings being slipped over them. The power factor of neon tube is quite low and is improved by using capacitors. The capacitors can, however, be placed only on the low voltage side of the transformer.

A number of precautions are prescribed for supply to high voltage luminous tube sign installations under IER 1956 (Rule No. 71).

Faults: Flickering may be due to;

- Transformer secondary voltage too low; this can be rectified by adjustment of the transformer tappings.

- Reduction of gas pressure in tube due to absorption of the gas into the electrodes, the tube may be removed and refilled by the manufacturers.

Neon tube installed in the open requires frequent cleaning, say 4 times per year. Care must be taken that the key of the opened lock switch is removed and held by the operator while work is being done.