On Off Controller or Two Position Controller:

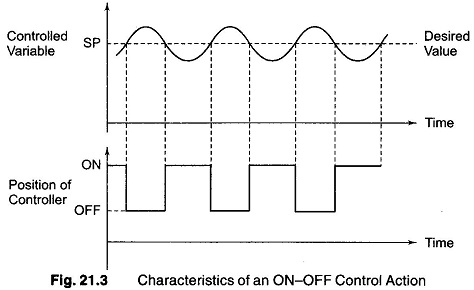

The On Off Controller or two position controller is the simplest, cheapest and the most used controllers. It is used in domestic heating systems, refrigeration, water tanks, etc. When the measured variable is below the set point, the controller is ON and the output signal has maximum value. When the measured variable is above the set point, the controller is OFF and output is zero.

Due to mechanical friction or arcing of electrical contacts, the controller actually goes on slightly below the set point and goes off slightly above the set point. This differential gap in the controller output may be deliberately increased to give decreased frequency of operation and reduced wear.

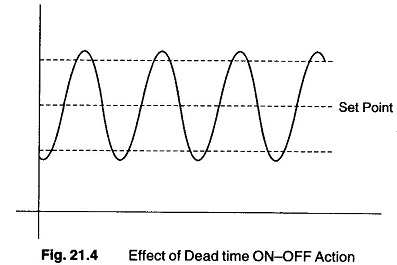

Dead time causes the value of the measured variable to go beyond the limit set by the differential gap, since the presence of dead time means a delay in corrective action of the controller. The greater the dead time, the greater the amplitude and period as shown in Fig. 21.4.

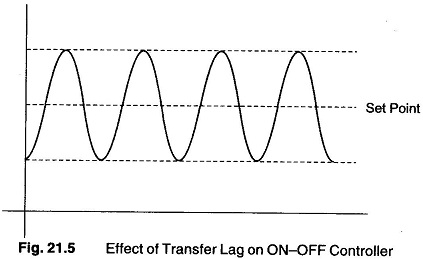

Transfer lag effect differs from the dead time effect, in that there is no delay in response, but rather, a slowing down of the response. Figure 21.5 shows the effect of transfer lag on a two position controller.

With both the dead time and the transfer lag, the measured variable exceeds the controller differential gap, as seen from Figs 21.4 and 21.5. With the transfer lag, all the changes are more gradual. Hence, the measured variable peaks due to the effect of transfer lag are rounded off on the two position controllers and are not as sharp as they are due to dead time effect.

The favourable conditions for using On Off Controller are as follows:

- The reaction rate should be slow.

- There should be little or no dead time.

- There should be little or no transfer lag.

However, in the On Off Controller, the process is never at the set point except momentarily on its way up and down. On Off Controller is however most suitable in practice due to its simplicity and low cost.