Overload Protection Relay:

Overload Protection Relay – Continuous balanced overloading of a machine causes overheating in the stator winding. An obvious solution to this is the application of overcurrent relays; but this is not usually provided because this discriminates by time, it must be arranged to discriminate with the slowest relay on the system which the generator is feeding, moreover in any event such a protection cannot detect a fault in the cooling system of the generator.

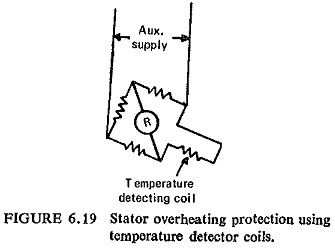

The most reliable method of detecting such a condition is by means of temperature detector coils embedded at various points in the stator winding arranged to provide an indication of the temperature conditions which exist over the stator winding.

Temperature detectors may be either thermocouples, thermistors, or resistance temperature detectors. The temperature detector coil forms one arm of the Wheatstone bridge circuit as shown in Fig (6.19).

Sets below 30 MW rating are not normally provided with embedded temperature detectors but are usually provided with thermal relays.

This type of Overload Protection Relay has a bimetallic strip heated by secondary current from the stator, the housing of the bimetallic strip is designed to have a heating and cooling characteristic similar to that of the machine. Such a Overload Protection Relay will however provide no protection against overheating due to the failure of the cooling system.