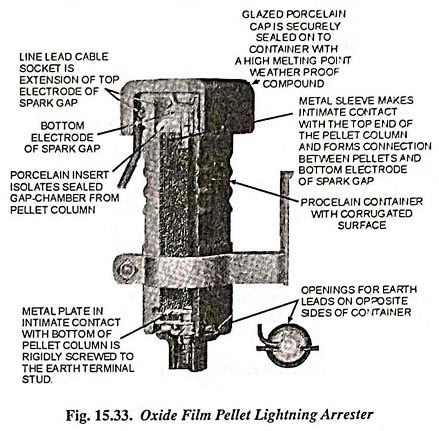

Oxide Film Lightning Arrester:

Oxide film lightning arrester operates on the fact that certain dry chemicals have the property to change rapidly from a good conductor to almost perfect insulator when slightly heated. For example, lead peroxide, which has a specific resistance of 25 ohms per mm cube at normal temperature, becomes red lead at about 150°C and has a specific resistance of the order of 600 mega ohms per mm cube.

It consists of 2.4 mm diameter pellets of lead peroxide with a thin porous coating of litharge arranged in a column and enclosed in a tube of diameter of about 6 cm and of height of 5 cm per kV of rating. Out of the two leads of the arrester upper is connected to the line, while the lower is connected to earth. The tube contains a series spark gap.

A single tube system is available for voltages up to 25 kV when the neutral is solidly grounded and 18 kV when the neutral is isolated or grounded through an inductive coil. For use on higher voltages several units in series are employed. The number of cells used in an arrester is such that the voltage per cell is about 300 volts.

When an overvoltage occurs an arc passes through the series spark gap and an additional voltage is applied to the pellet column and a discharge takes place. After the discharge, the resistance of the pellet column increases till only very small current can flow through it. This small current is finally interrupted by the series spark gap.

Advantages:

The great advantage of oxide film lightning arrester is that it does not require daily charging, and it may thus be installed at points on transmission systems where daily attendance is difficult or expensive to provide.

The impulse ratio of such an oxide film lightning arrester is more than unity.