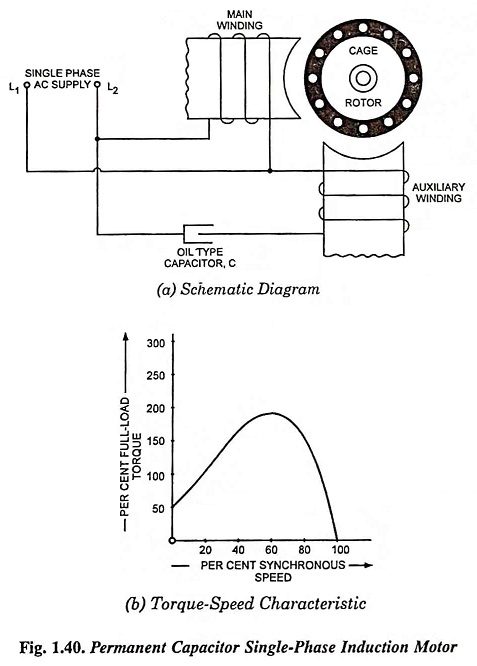

Permanent Capacitor Single Phase Induction Motor:

Permanent capacitor single phase induction motor, also sometimes called the single-value capacitor—run motor, has two stator windings placed mutually 90 electrical degrees apart. The main or running winding is connected directly across the single phase ac supply. A capacitor in series with the auxiliary winding is also connected across the supply lines.

The auxiliary winding is always in the motor circuit, and therefore, the operation of the motor when loaded resembles more closely to that of a 2-phase motor. One advantage of such operation is that the rotating field developed by the two stator windings is a more nearly uniform, and therefore, the motor is quieter in operation. The other advantages of such a motor are (i) increased pull-out torque (ii) a higher power factor (0.8-0.95), (iii) higher operation efficiency (55-65 per cent) and (iv) smaller full-load line current.

The Permanent capacitor single phase induction motor is more expensive than the equivalent resistance-start or capacitor—start induction motor mainly owing to the increased cost of auxiliary winding which is now wound with thicker wire and consists of as many turns as the main winding.

A unique feature of such a motor is that it can be very easily reversed by an external switch, provided the two windings are identical. Because of absence of starting switch it is possible to reverse the leads of either winding while the motor is running.

Such motors are widely used in table and ceiling fans, blowers, oil burners, room coolers, portable tools, other domestic and commercial electrical appliances, where low starting torque is required.

Because of the simplicity of reversal of motor, such motors are often used to operate devices that must be moved back and forth frequently such as induction regulators, rheostats, furnace controls, valves and arc-welding controls.

Because of the absence of starting switch, it is possible to run a permanent (or single value) capacitor-run motor over a wide range of speeds, and such a motor has many applications where adjustable speed is required. Such a motor can be arranged for an adjustable speed by the use of a tapped winding or an auto-transformer regulator. It is known that the torque developed in an induction motor is proportional to the square of the applied voltage. For a given load, therefore, if the applied voltage is reduced, the motor will operate with increased slip to develop the required torque. Thus the speed can be controlled by varying the voltage applied to the motor.