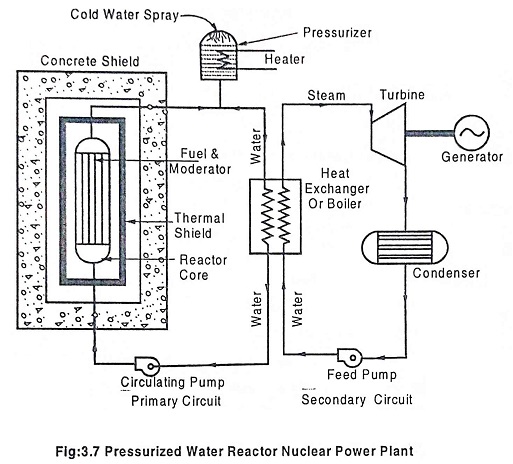

Pressurized Water Reactor (PWR) – Working Principle:

Pressurized Water Reactor uses enriched U as fuel. In this reactor, water is used as coolant and moderator. The water passes through the reactor core and becomes hot water. The hot water flows to a heat exchanger (steam generator) where its heat is transferred to the feed water to generate steam.

In order that water may not boil and remain in liquid state, it is kept under a light pressure of about 150 atm. The primary circuit contains ‘pressurizer’. Pressurizer is a simple pressure vessel with a heater at the bottom and a water spray at the top. The top of the pressurizer is filled with steam at primary circuit pressure. If the primary circuit pressure drops, the heater is operated which generates steam and increases the steam content in the vessel. This results in the increase of pressure in the primary circuit.

And if the primary circuit pressure becomes too high, the cold water is sprayed in the pressurizer. This condenses the steam and reduces the primary circuit pressure.

Advantages of Pressurized Water Reactor:

- In this type, water is used as coolant, moderator and reflector [Water is cheap and available in plenty].

- The Pressurized water reactor is compact.

- It requires less number of control rods.

- The separation of secondary circuit from primary provides the safety and prevents the radiation.

- In this type, the turbine, feed heaters and condenser can be inspected freely.

- It reduces the fuel cost.

Disadvantage:

- The cost of pressuriser is more

- Thermodynamic efficiency of this reactor is low.

- The corrosion is accelerated in the presence of high pressure, high temperature water.

- For fuel changing, it requires a lot of time.

- Due to the γ – reactions, uneven heating is caused and this results in thermal stresses and pressure stresses and makes design difficult.