Protection of Alternators:

The generating units, especially the larger ones, are relatively few in number and higher in individual cost than most other equipment’s. Therefore, it is desirable and necessary to provide Protection of Alternators to cover the wide range of faults which may occur in the modern generating plant.

Some of the important faults which may occur on an alternator are :

-

Failure of prime-mover

-

Failure of field

-

Overcurrent

-

Overspeed

-

Overvoltage

-

Unbalanced loading

-

Stator winding faults

1. Failure of Prime-Mover:

When input to the prime-mover fails, the alternator runs as a synchronous motor and draws some current from the supply system. This motoring conditions is known as “inverted running“.

- In case of turbo-alternator sets, failure of steam supply may cause inverted running. If the steam supply is gradually restored, the alternator will pick up load without disturbing the system. If the steam failure is likely to be prolonged, the machine can be safely isolated by the control room attendant since this condition is relatively harmless. Therefore, automatic protection is not required.

- In case of hydro-generator sets, Protection of Alternators against inverted running is achieved by providing mechanical devices on the water-wheel. When the water flow drops to an insufficient rate to maintain the electrical output, the alternator is disconnected from the Therefore, in this case also electrical protection is not necessary.

- Diesel engine driven alternators, when running inverted, draw a considerable amount of power from the supply system and it is a usual practice to provide Protection of Alternators against motoring in order to avoid damage due to possible mechanical seizure. This is achieved by applying reverse power relays to the alternators which *isolate the latter during their motoring action. It is essential that the reverse power relays have time-delay in operation in order to prevent inadvertent tripping during system disturbances caused by faulty synchronizing and phase swinging.

2. Failure of field:

The chances of field failure of alternators are undoubtedly very rare. Even if it does occur, no immediate damage will be caused by permitting the alternator to run without a field for a short-period. It is sufficient to rely on the control room attendant to disconnect the faulty alternator manually from the system bus-bars. Therefore, it is a universal practice not to provide automatic protection against this contingency.

3. Overcurrent:

It occurs mainly due to partial breakdown of winding insulation or due to overload on the supply system. Overcurrent protection for alternators is considered unnecessary because of the following reasons :

- The modern tendency is to design alternators with very high values of internal impedance so that they will stand a complete short-circuit at their terminals for sufficient time without serious overheating. On the occurrence of an overload, the alternators can be disconnected manually.

- The disadvantage of using overload Protection of Alternators is that such a protection might disconnect the alternators from the power plant bus on account of some momentary troubles outside the plant and, therefore, interfere with the continuity of electric service.

4. Overspeed:

The chief cause of overspeed is the sudden loss of all or the major part of load on the alternator. Modern alternators are usually provided with mechanical centrifugal devices mounted on their driving shafts to trip the main valve of the prime-mover when a dangerous overspeed occurs.

5.Over-voltage:

The field excitation system of modern alternators is so designed that over-voltage conditions at normal running speeds cannot occur. However, over voltage in an alternator occurs when speed of the prime-mover increases due to sudden loss of the alternator load.

In case of steam-turbine driven alternators, the control governors are very sensitive to speed variations. They exercise a continuous check on over speed and thus prevent the occurrence of over-voltage on the generating unit. Therefore, over-voltage protection is not provided on turbo-alternator sets.

In case of hydro-generator, the control governors are much less sensitive and an appreciable time may elapse before the rise in speed due to loss of load is checked. The over-voltage during this time may reach a value which would over-stress the stator windings and insulation breakdown may occur. It is, therefore, a usual practice to provide over-voltage protection on hydro-generator units. The over-voltage relays are operated from a voltage supply derived from the generator terminals. The relays are so arranged that when the generated voltage rises 20% above the normal value, they operate to

- trip the main circuit breaker to disconnect the faulty alternator from the system

- disconnect the alternator field circuit

6. Unbalanced loading:

Unbalanced loading means that there are different phase currents in the alternator. Unbalanced loading arises from faults to earth or faults between phases on the circuit external to the alternator. The unbalanced currents, if allowed to persist, may either severely burn the mechanical fixings of the rotor core or damage the field winding.

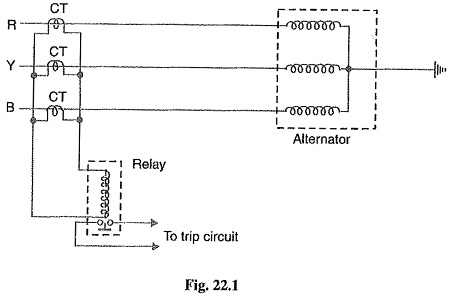

Fig. 22.1 shows the schematic arrangement for the Protection of Alternators against unbalanced loading. The scheme comprises three line current transformers, one mounted in each phase, having their secondaries connected in parallel. A relay is connected in parallel across the transformer secondaries. Under normal operating conditions, equal currents flow through the different phases of the alternator and their algebraic sum is zero. Therefore, the sum of the currents flowing in the secondaries is also zero and no current flows through the operating coil of the relay. However, if unbalancing occurs, the currents induced in in the secondaries will be different and the resultant of these currents will flow through the relay. The operation of the relay will trip the circuit breaker to disconnect the alternator from the system.

7. Stator winding faults:

These faults occur mainly due to the insulation failure of the stator windings. The main types of stator winding faults, in order of importance are :

- fault between phase and ground

- fault between phases

- inter-turn fault involving turns of the same phase winding

The stator winding faults are the most dangerous and are likely to cause considerable damage to the expensive machinery. Therefore, automatic protection is absolutely necessary to clear such faults in the quickest possible time in order to minimize the extent of damage. For Protection of Alternators against such faults, differential method of protection (also knows as Merz-Price system) is most commonly employed due to its greater sensitivity and reliability.