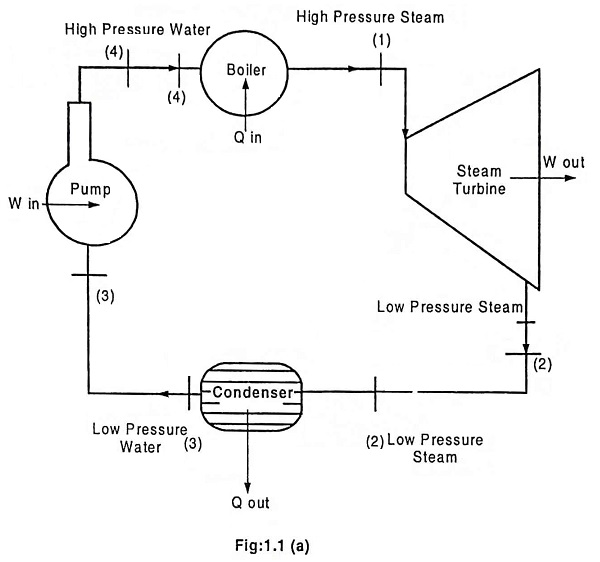

Rankine Cycle (Simple Steam Power Cycle):

Rankine cycle is the theoretical cycle on which the steam turbine (engine) works.

Boiler

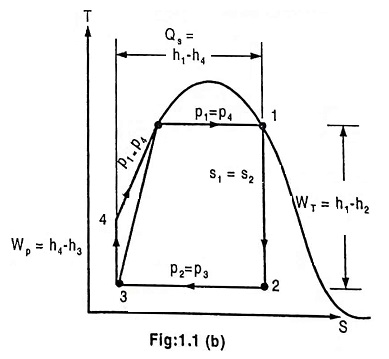

Refer the process (4) to (1): Feed water is passing to the boiler. Heat is added to the water in the boiler. The water gets heated and becomes dry saturated steam (or) super heated steam.

Turbine

Refer the process (1) to (2): The high pressure steam is expanding in the turbine, thus work is produced. i.e., The turbine rotates. The steam leaves the turbine as low pressure steam.

Condenser

Condenser is used to convert the low pressure steam into water.

Refer the process (2) to (3): The low pressure steam is passing through condenser where heat is liberated from the steam. So the steam becomes water. To cool the steam, separate cooling water is circulated through condenser from the cooling tower. This cooling water and the steam in rankine cycle will not mix together in most of the condensers.

Pump

Refer the process (3) to (4): The water leaving condenser is pumped to the boiler by pump. Usually, pump work is neglected since it is very small work when compared to turbine work output.

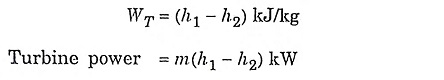

1 – 2 Turbine work

Turbine work output (Isentropic expansion in Turbine)

where

- m = Mass flow rate of steam in kg/sec.

- h1 and h2 can be taken from steam table for p1 and p2 respectively.

- (p1 = high pressure (or) boiler pressure (or) inlet to turbine pressure)

- (p2 = low pressure (or) condenser pressure)

Also, we can use Mollier diagram to find h1 and h2.

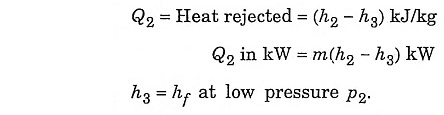

2 – 3 Constant pressure condensation

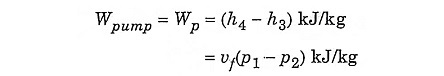

3 – 4 Pump Work

where

- vf for p2 from steam table

- p1 and p2 in kPa

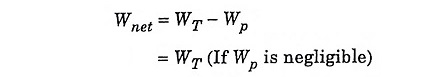

Net Work

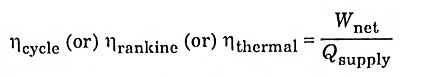

Thermal Efficiency

It is the ratio of net work done to the heat supplied.

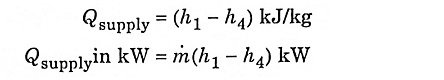

4 – 1 Heat Supplied in Boiler: Qsupply

(Constant pressure heat supply)

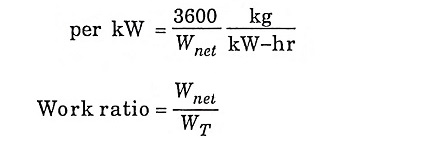

Specific steam consumption. ‘SSC’ (or) steam flow rate per kW