Repulsion Motor – Construction, Working Principle and Applications:

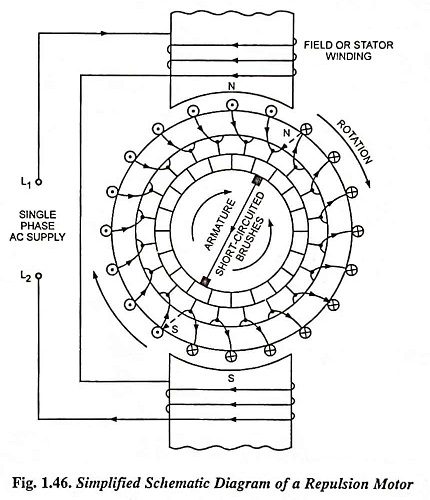

The characteristics of repulsion motors are similar to those of a series motor, i.e., high starting torque and high light-load speed. Its construction is also similar to that of a series motor except that armature is short circuited on itself instead of being connected in series with the stator. Simplified schematic diagram is shown in Fig. 1.46. A repulsion motor develops a torque in the direction in which the brushes are shifted from the field axis.

The torque developed by a repulsion motor should be maximum, theoretically, when the space angle between the pole axis and brush axis is 45°, but in practice the angle of inclination is about 15-25 electrical degrees.

The repulsion motor has better commutation than the series motor at speeds below synchronous speed and poor commutation at very high speeds. The direction of rotation of a repulsion motor can be reversed by shifting the brushes round the commutator, on the other side of the field axis. Speed control can be affected by varying the applied voltage to motor or by mounting the brushes on a rocker which can be rotated by a lever handle mounted on the motor end-shield.

The repulsion motor has high starting torque (about 3-5 times full-load torque) and moderate starting current (about 3-4 times full-load current) but poor speed regulation. Shifting the brushes during operation gives a wide range of speed control, as high as 6:1 ratio, and yet provides a continuous variation. The upper speed is not limited by frequency. The motor is a reversing type, and the direction may be changed during rotation.

Disadvantages:

The drawbacks of repulsion motors are (i) speed variations with the variations in loads-dangerously high at no load (ii) low power factor, except at high speeds, (iii) tendency to spark at the brushes-sparking at the brushes is negligible at the rated speed which usually occurs near synchronous speed (iv) higher cost and (v) more attention and maintenance is required.

Applications:

The repulsion motor has never enjoyed popularity. The motor is used where sturdy motor with large starting torque and adjustable speed is required. Most common use of this type of motor is in the coil winders in which the operator adjusts the speed by shifting the brushes; the motor is equipped with a special lever mechanism, that shifts the brushes when a foot treadle is pressed.

The ratings in which the repulsion motors are built is limited due to commutation problems. The usual rating of the repulsion motor does not exceed 5 kW.