Resistive Transducer | Resistive Potentiometer | Resistance Pressure Transducer:

Resistive Transducer are those in which the resistance changes due to a change in some physical phenomenon. The change in the value of the resistance with a change in the length of the conductor can be used to measure displacement.

Strain gauges work on the principle that the resistance of a conductor or semiconductor changes when strained. This can be used for the measurement of displacement, force and pressure.

The resistivity of materials changes with changes in temperature. This property can be used for the measurement of temperature.

Resistive Potentiometer:

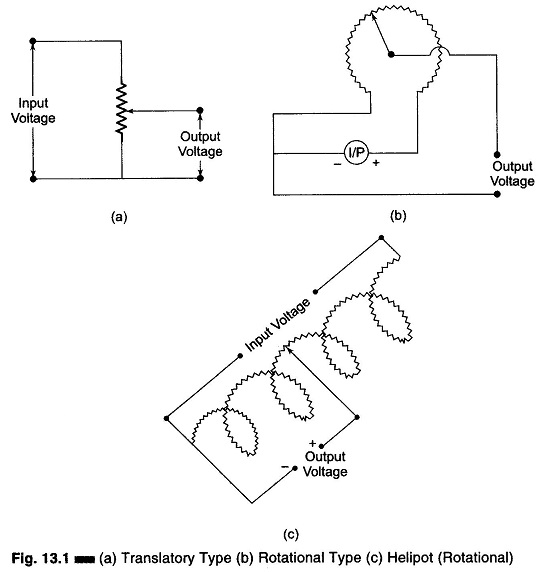

A resistive potentiometer (pot) consists of a resistance element provided with a sliding contact, called a wiper. The motion of the sliding contact may be translatory or rotational. Some have a combination of both, with resistive elements in the form of a helix, as shown in Fig. 13.1(c). They are known as helipots.

Translatory resistive elements, as shown in Fig. 13.1(a), are linear (straight) devices. Rotational resistive devices are circular and are used for the measurement of angular displacement, as shown in Fig. 13.1(b).

Helical resistive elements are multi turn rotational devices which can be used for the measurement of either translatory or rotational motion. A potentiometer is a passive transducer since it requires an external power source for its operation.

Advantage of Potentiometers:

- They are inexpensive.

- Simple to operate and are very useful for applications where the requirements are not particularly severe.

- They are useful for the measurement of large amplitudes of displacement.

- Electrical efficiency is very high, and they provide sufficient output to allow control operations.

Disadvantages of Potentiometers:

- When using a linear potentiometer, a large force is required to move the sliding contacts.

- The sliding contacts can wear out, become misaligned and generate noise.

Resistance Pressure Transducer:

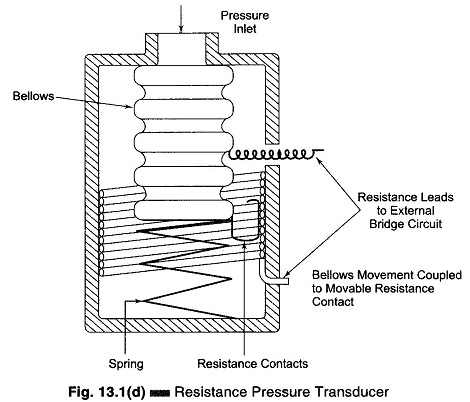

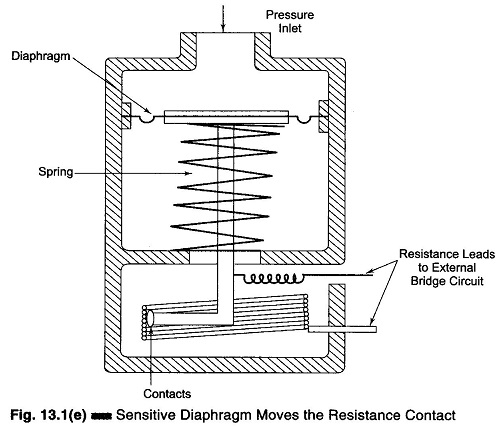

Measurement in the resistive type of transducer is based on the fact that a change in pressure results in a resistance change in the sensing elements. Resistance pressure transducers are of two main types. First, the electromechanical resistance transducer, in which a change of pressure, stress, position, displacement or other mechanical variation is applied to a variable The other resistance transducer is the strain gauge, where the stress acts directly on the resistance. It is very commonly used for stress and displacement measurement in instrumentation.

In the general case of pressure measurement, the sensitive resistance element may take other forms, depending on the mechanical arrangement on which the pressure is caused to act.

Figure 13.1(d) and (e) show two ways by which the pressure acts to influence the sensitive resistance element, i.e. by which pressure varies the resistance They are the bellow type, and the diaphragm type. (Yet another is the Bourdon tube of pressure gauge).

In each of these cases, the element moved by the pressure change is made to cause a change in resistance. This resistance change can be made part of a bridge circuit and then taken as either ac or dc output signal to determine the pressure indication.