Selection of Motor Power Rating:

The Selection of Motor Power Rating of a motor for a specific application must be carefully chosen to achieve economy with reliability. Use of a motor having insufficient rating, either fails to drive the load at its normal productive level or lowers the productivity and reliability through frequent damages and shut-downs due to overloading of the motor and power modulator.

On the other hand, if power rating is decided liberally, the extra initial cost and extra loss of energy due to operation below rated power makes the choice uneconomical. Furthermore, induction and synchronous motors operate at a low power factor when operating below the rated power.

When a motor operates, heat is produced due to losses (copper, iron and friction) inside the machine and its temperature rises. As the temperature increases beyond ambient value, a portion of heat produced flows out to the surrounding medium. The amount of outflow of heat is a function of temperature rise of motor above the ambient value. As motor temperature rises, the heat outflow increases and equilibrium ultimately sets in when the heat generated becomes equal to heat dissipated into the surrounding medium.

Motor temperature then reaches a steady state value. Steady state temperature depends on power loss, which in turn depends on the output power of the machine. Since temperature rise has a direct relationship with the output power, it is termed Thermal Loading on the machine,

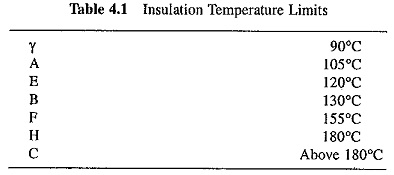

Steady state temperature is not the same at various parts of the machine. It is usually highest in the windings because loss density in conductors is high and dissipation is slow; since the conductors which are wrapped in insulating material are partly embedded in slots and thus are not directly exposed to the cooling air. Among the various materials used in machine, the insulation has lowest temperature limit. Depending on the temperature limits, insulating materials employed in electric machines are divided into classes γ, A, E, B, F, H, C. Table 4.1 lists the temperature limits of these insulation (IS: 1271-1958).

When operating for a specific application, motor rating should be carefully chosen to ensure that the insulation temperature never exceeds the prescribed limit, otherwise either it will lead to its immediate thermal breakdown causing short circuit and damage to winding, or it will lead to deterioration of its quality resulting into thermal breakdown in near future.

For loads which operate at a constant power and speed, determination of motor power rating is simple and straightforward. But only a few loads operate at a constant speed and power. Most loads operate at variable power and speed, and the patterns of these variations are different for different applications.

This Selection of Motor Power Rating has three objectives:

- To obtain a suitable thermal model for the machine which can be utilized in calculation of motor ratings for various Classes of Motor Duty.

- Categorisation of load variation with time into certain standard categories which are termed as Classes of Duty of motor.

- To present methods for calculating motor ratings for various classes of duty.