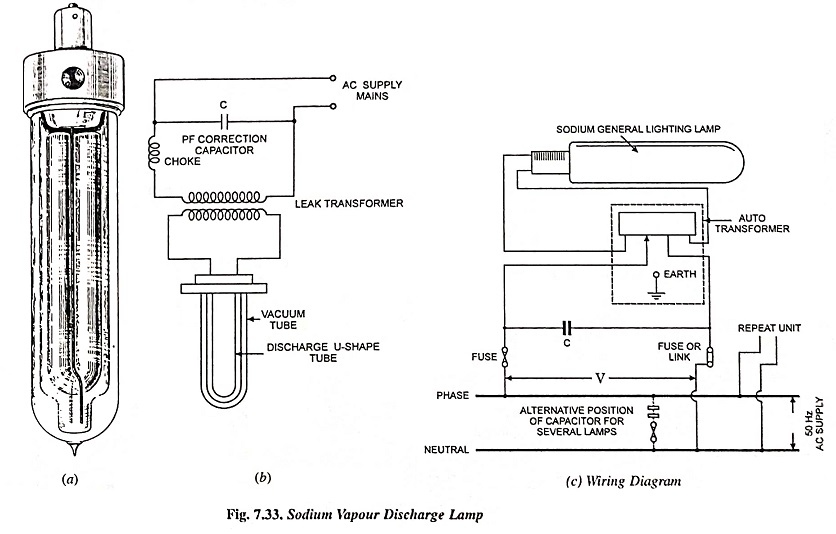

Sodium Vapour Lamp – Construction, Working and Wiring Diagram:

Principally the sodium vapour discharge lamp consists of a bulb containing a small amount of metallic sodium, neon gas, and two sets of electrodes connected to a pin type base. The presence of neon gas serves to start the discharge and to develop enough heat to vaporize the sodium. Since long discharge paths are necessary, therefore, the discharge envelope is usually bent into U shape. The lamp operates at a temperature-like 300°C and in order to conserve the heat generated and assure the lamp operating at normal air temperatures the discharge envelope is enclosed in a special vacuum envelope designed for this purpose. The lamp must be operated horizontally, or nearly so, to keep the sodium well spread out along the tube, although some small lamps may be operated vertically, lamp cap up. Care should be taken in handling these lamps, particularly when replacing inner U-tube, for if it is broken and sodium comes in contact with moisture fire will result.

The sodium vapour lamp is only suitable for alternating current, and therefore, requires choke control. This requirement is met by operating the lamp from a stray field, step-up, tapped auto-transformer with an open-circuit secondary voltage of 470 to 480 volts. The uncorrected power factor is very low, about 0.3, and a capacitor must be used to improve the power factor to about 0.8.

When the lamp is not in operation, the sodium is usually in the form of solid deposited on the side walls of the tube, therefore, at first when it is connected across the supply mains the discharge takes place in the neon gas and gives red-orange glow. The metallic sodium gradually vaporizes and then ionizes, thereby producing the characteristic monochromatic yellow light, which makes objects appear as grey. The lamp will come up to its rated light output in approximately 15 minutes. It will restart immediately should the power supply be momentarily interrupted since the presence of vapour is quite low and the voltage is sufficient to restrike the arc.

The wiring diagram of sodium vapour lamp(s) is given in Fig. 7.33 (c).

The efficiency of a sodium vapour lamp under practical conditions is about 40-50 lumens/watt. The major application of this type of lamp is for highway and general outdoor lighting where colour discrimination is not required, such as street lighting, parks, rail yards, storage yards etc. Such lamps are manufactured in 45, 60, 85 and 140 watt ratings. The average life is about 3,000 hours and is not affected by voltage variations. At the end of this period the light output will be reduced by 15% due to aging.

The lamp fails to operate when

- the filament breaks or burns out,

- the cathode stops to emit electrons,

- the sodium particles may concentrate on one side of the tube,

- the lamp tube is blackened owing to sodium vapour action on the glass, in which case the output will be reduced.

Advantages:

- It has higher efficiency.

- Longer Life.

- Energy Efficient is more.

- It works better on rainy season.

Disadvantages:

- It takes around 10 minutes to glow full light output.

- It requires additional transformer.