Speed Control of Single Phase Induction Motor:

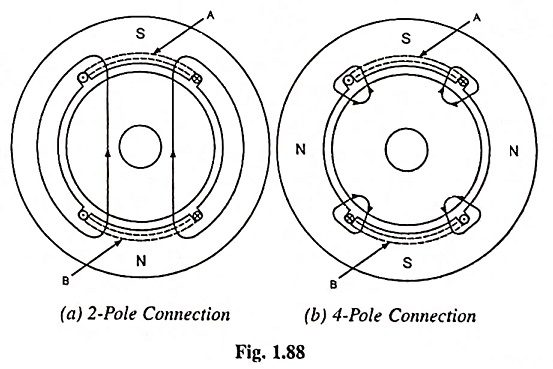

The stator winding of a speed control of single phase induction motor can easily be arranged to give two synchronous speeds, one double the other. In Fig. 1.88 (a) the connections for two pole motors are shown in which two coils A and B have been connected in series with their mmfs helping each other. If the connections to coil B are reversed so that both the coils are again in series but their mmfs opposing each other, as shown in Fig. 1.88 (b), 4 poles are produced and the synchronous speed is reduced to half. Similarly a four-pole motor can be reconnected to give 8 poles. The change from one speed to the other is easily and quickly accomplished by means of a two-pole double-throw switch.

Furthermore, because of the comparatively small power handled by single-phase induction motors, excessive slip to give a slight reduction in speed is not serious, from the stand point of waste of power, as in case of a 3-phase induction motors. For that reason in various cases, such as for fan and blower applications where speeds of 1,100 or 1,300 rpm might be required, it is not unusual to employ 4-pole motor with high slip. This can be accomplished (i) by using high rotor resistance, in which case no variation in speed is introduced, but the motor displays a drooping speed curve; or (ii) by reducing the voltage applied to the stator winding. For this purpose variable resistance or tapped reactance coil in series with the motor can be employed for speed regulation. This method is inefficient, gives large variations in speed with the variations in load, but it is much used inspite of these drawbacks.

Alternatively, the voltage applied to the motor stator winding can be varied either by means of a transformer with taps on its secondary or by means of a variac, which provides the maximum possible number of taps and thus gives finest speed adjustment. This is one of the simplest methods of speed control of fractional kilowatt motors.

The speed control of single phase induction motor can also be controlled by employing tapped exciting winding, so that the constant voltage source may be impressed across the entire winding or some part of it. By this means, a normal speed and a single reduced speed are provided.

Speed control because of its more general use, has brought about the standardization of fan speeds, allowing the use of high slip motors. A squirrel cage motor with 8-10 per cent slip and with low pull-out torque operates satisfactorily not only for constant speed drives, but also for adjustable speed drives through the use of voltage control on the stator winding. With this method of speed control of single phase induction motor, the torque-speed characteristics resemble with those of a wound rotor motor with different number of external resistances in the rotor circuit.