Spot Welding – Definition, Working Principle, Application and Advantages:

By definition, spot welding is a form of resistance welding in which the parts or pieces are joined in spots, accompanied by heated relatively small sections of the parts or pieces between suitable electrodes under pressure.

Spot welding is perhaps the most widely used form of resistance welding. It is characterized by low cost, speed, and dependability making it a common electrical resistance welding process.

Working Principle:

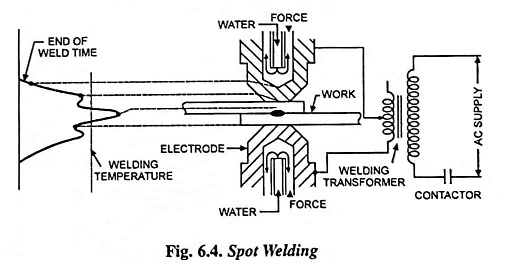

Spot welding is usually used for joining or fabricating sheet metal structure. This type of welding only provides mechanical strength and is neither airtight nor watertight. For obtaining good welds having strength, and to avoid the excessive heating effects due to foreign filmson sheet surfaces, it is desirable to clean the sheets thoroughly before welding. In this type of welding the workpieces to be welded are pressed together by mechanical pressure exerted through electrodes (made of pure copper or alloy of copper) as shown in Fig. 6.4 and then supply is switched on for a particular period. The mechanical pressure may be developed by a foot lever or by air pressure or by hydraulic cylinders. The metal in the zone of pressure gets up heated to fusion and the joint thus made gets cooled under pressure. The pressure remains applied till the weld cools and regains sufficient strength. Current required is above 5,000 A and the voltage between the electrodes is usually less than 2 volts. The open-circuit voltage is less than 12 volts. The time period of flow of current varies widely depending upon the thickness of sheets, kinds of metal etc. For thin sheets this period is about 1/50 second for each 0.25 mm of total thickness of the two sheets to he joined.

In order to avoid electrode sticking it is necessary to avoid heating of junction faces between electrodes and work. This is achieved (i) by using water-cooled electrodes and (ii) by employing electrodes made of material having high electrical as well as thermal conductivity. In order to minimize the wear and tear at the tip of the electrodes it is necessary to employ electrodes made of material having high mechanical strength.

Efficient spot welds are possible only by a correct combination of current, pressure, and welding time. The heat developed being proportional to the product of the welding time and the square of the current, it is possible to obtain good welds by employing either low currents for a longer duration or higher currents for a shorter duration. Longer welding time usually produces stronger welds but this involves lot of distortion of workpieces, electrode maintenance and high energy expenditure. The welding pressure required is determined on the basis of a specific electrode pressure of 7 kg per sq.mm over the electrode tip area. In view of the fact, however, that plates will not always be perfectly flat, a certain additional pressure is usually recommended, which will overcome slight distortion of the plates without the resultant necessary welding pressure.

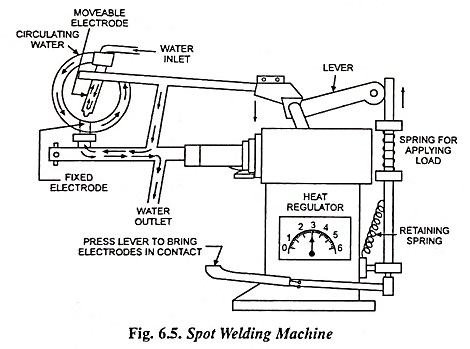

For obtaining good joints spot welding machine (Fig. 6.5), which makes the welding operation independent of the operator by automatically controlling welding current, pressure, and timing, once the same have been set correctly, may be employed. By toggle mechanism electrodes are pressed on the work and according to the requirement the current can be turned on and off. In certain machines the electrodes of spot welders are equipped with water cooling arrangement. In such cases the electrodes are made hollow and the water is circulated through them. Spot welding machines are of capacities ranging from 10 to 150 kVA.

Application and Advantages:

Spot welding is applicable for joining components made from plate material, the plate thickness being limited (usually to 10 or 12 mm) by the pressure and current capacity of the available spot welding machine. It has an advantage over projection welding in cases where the number of welds required is relatively small, where the size of the job is too large for the capacity of projection welders, and where the design allows the necessary spacing and arrangement of the welds to be obtained. The lower cost of the equipment makes spot welding economical for small quantities.