Starting and Speed Control of Single Phase AC Series Motor:

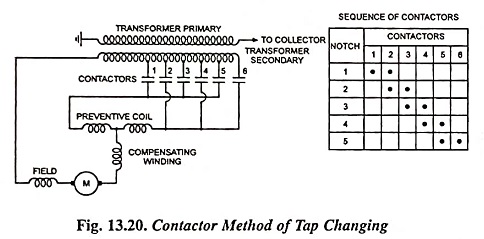

The starting and speed control of single phase AC series motor is carried out by varying the applied voltage. As the operating voltage for a single phase series motor is very low (about 300 volts), thus, transformer forms an essential part of the locomotive equipment and, therefore, variable voltage for both starting and speed control of single phase AC series motor can be obtained by means of tappings on the transformer without requiring any additional equipment for this purpose. The transformer tappings are usually provided on It side of the transformer in order to avoid insulation difficulties but 11,000 volt locomotives have been built with hv tappings, which enables a lighter construction to be used on account of much lower currents to be dealt with. As no external resistance is required for starting purpose, so there is no loss of power and each control point becomes a running point. The regulation of voltage is affected by the contactor method of tap changing, as shown in Fig. 13.20.

A preventive coil is employed for reducing the circulating current flowing on account of short circuiting of a section of the winding of the transformer between the tappings. Preventive coil (choking coil having high resistance) is inserted between the terminals of two groups consisting of tappings 1, 3, 5 and 2, 4, 6 as shown in the Fig. 13.20. The motor is connected to the centre point of the preventive coil. Two contactors, connected to the adjacent tappings (1 and 2 or 2 and 3 or 3 and 4 or 4 and 5 or 5 and 6) are closed on each notch of the controller. Each contactor, therefore, carries approximately one half of the total current required. For changing-over voltage from one value to another one contactor is opened and another contactor belonging to the same group is closed.

An important advantage of this method is that each notch provides a running position, so that many running speeds are available. Between 6 and 12 tappings are usually provided, giving a corresponding number of economical speeds.

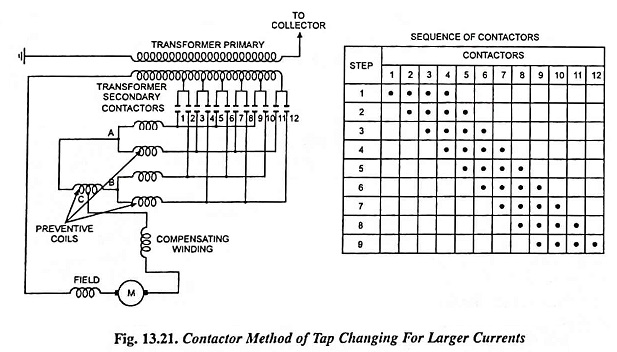

In case larger currents are to be handled by the contactors (for large capacity traction motors), a larger number of contactors are to be employed simultaneously so that the current is divided between them and each contactor has not to deal more than a pre-specified design value.

Contactor method of tap changing for larger currents (over 1,000 A) is shown in Fig. 13.21. In this method four adjacent contactors are connected to the same notch of the controller. There are three preventive coils, also called ‘bridging coils‘ arranged in such a fashion as to facilitate the correct division of current among the contactors.

The ac contactors are quite different from dc contactors. In general, dc contactor is much lighter than the ac contactor and needs less power for its operation. Other special features of ac contactors are (i) laminated magnetic circuit (ii) provision of shading coil in order to avoid chattering of contactors.