Stator Overheating Protection:

Stator Overheating Protection – Generally stator overheating is caused by sustained overloads or by cooling system failure. Overheating because of short-circuited laminations is very localized, and it is just a matter of chance whether it can be detected before serious damage is caused. It is not practicable to provide overload protection by backup stator fault overcurrent protection as backup overcurrent protection is usually set for sensing fault currents and should not trip for overloads.

Electrical overcurrent relays cannot sense the winding temperature accurately because temperature rise depends on I2Rt and also on cooling. Electrical protection cannot detect failure of the cooling system.

The practice is to embed resistance temperature-detector coils or thermocouples in the slots below the stator coils of the generators of large capacity (above 1 MVA) for protection against overheating. Enough of such detectors are located at different places in the windings so that an indication can be obtained of the temperature conditions throughout the stator.

Several of the detectors that provide the highest temperature indication are selected for use with temperature indicator or recorder usually having alarm contacts, or the detector providing the highest indication may be arranged to operate a temperature relay to sound alarm.

Supplementary temperature devices may be provided for monitoring the cooling system; such devices would give the earliest alarm in the event of failure of cooling system. But it is usually realized that the stator temperature detectors and alarm devices are sufficient

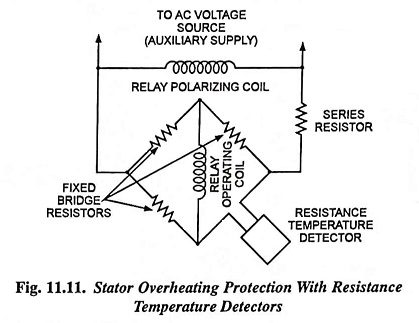

Detector operated relaying system using a Wheatstone bridge circuit and a directional relay is shown in Fig. 11.11.