Steam Condenser – Definition, Working Principle and Types:

Steam condenser is a device in which the exhaust steam of a turbine is condensed by means of cooling water below atmospheric pressure. By decreasing the exhaust pressure of steam below atmosphere, the efficiency of the power plant is greatly improved. The condensed steam is called condensate which can be reused in the boiler, saving the cost of water. This also reduces, the capacity of the water softening plant.

The condensers are mainly classified into two types, namely

- Mixing type or Jet condensers.

- Non-Mixing Type or Surface condensers.

1. Mixing type or Jet condensers:

In this type of condensers, the exhaust steam from turbine (prime mover) and cooling water come in direct contact with each other and as a result, the steam condenses into water. So, these condensers are also called as Direct contact condensers. Usually water is introduced in the form of a spray from a jet. The temperature of the condensate is the same as that of the cooling water leaving the condenser.

As the condensate is not free from salt and pollutants, it cannot be used as feed water to the boiler. Hence these condensers are preferred only where ample good quality water is available.

Jet condensers are divided into two types

- Parallel flow condensers: Here steam and cooling water flow in the same direction.

- Counter flow condensers: Here steam and cooling water flow in opposite directions.

Jet condensers are never used in modern power plants and hence are not discussed here.

2. Non-Mixing Type or Surface condensers:

A surface condenser is a commonly used term for a water-cooled shell and tube heat exchanger. These condensers convert steam to water at a pressure below atmospheric pressure. Here, the exhaust steam and cooling water do not come in contact.

Classification of Surface Condensers:

The cooling water flow through a series of tubes and the exhaust steam passes over these tubes. Condensation of a steam is due to heat transfer by conduction and convection.

Surface Condensers are mainly of two types

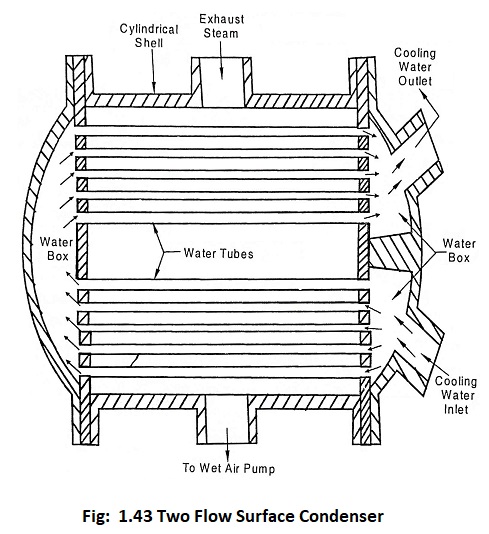

- Two flow condenser: Two flow condenser consists of air tight cast iron cylindrical shell. A number of water tubes are fixed in the tube plates as shown in 1.43. If the cooling water is impure, condenser tubes will be made up of red brass. In two flow steam condenser, cooling water travels twice once from inlet-water box to end water box and once from end water box to outlet water box.

- Multi flow condenser: In multi flow condenser, the rate of heat exchange is rapid but the power required to circulate the cooling water is also more.

According to the direction of flow of steam, the surface condenser can be classified as,

- Down flow surface condenser

- Central flow surface condenser

- Inverted flow surface condenser

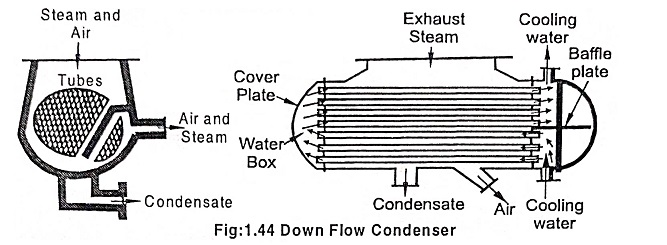

1. Down Flow Surface Condenser:

In Down flow surface condenser, steam enters through the top of the condenser vessel and it comes down over the cooling water pipes. Then the steam starts to condense, the pressure as well as temperature of the condensate get decreased. Two separate pumps are employed for the extraction of condensate and the air. The air exit is shielded from the down stream of the condensate by means of baffle plate and thus air is extracted with only a comparatively small amount of water vapour. The condensate is extracted from the bottom of the condensate with the help of the condensate extraction pump.

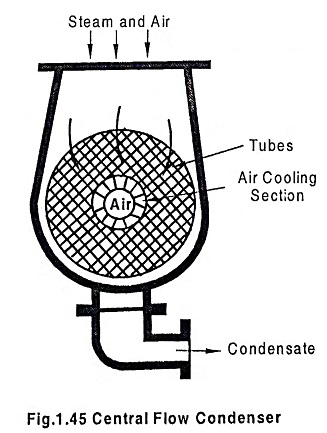

2. Central Flow Surface Condenser:

It is also shell type cross flow heat exchanger at the center of which is located the suction of an air extraction pump so that the entire steam moves radially inward and comes in better contact with the surfaces of nest of the tubes in which the cooling water flows. The steam condensate is extracted from the bottom by the condensate extraction pump.

3. Inverted Flow Type:

Here, the air extraction pump is located at the top of the condenser. The steam enters through the bottom and flows upwards in cross flow with the cooling water flowing in the tubes. The steam after being condensed on the outer surface of water tubes is removed by the condensate extraction pump situated at the bottom of the condenser.

Advantages of Surface Condenser:

- Improves plant efficiency.

- Auxiliary power requirement is less.

- Any kind of feed water can be used.

- There is no mixing of cooling water and steam.

- So the condensate can be reused as boiler feed water directly.

- This condenser develops high vacuum and hence is suitable for large power plants.

Disadvantages of Surface Condenser:

- High manufacturing and maintenance cost.

- Requires large floor space.

- Requires large quantity of cooling water.