Systems of Track Electrification DC Electrification System:

The substations are necessary for control of electric supply to a considerably long network in systems of track electrification DC electrification system.

DC Substations:

These substations are required for tramways, trolley buses and railways. Their functions are to (i) step down the transmission voltage to the utilization level (ii) convert it into dc and (iii) sectionalizing the overhead equipment. Such substations, therefore, consist of step-down transformers, converting machinery, ac circuit breaker, dc circuit breaker and smoothing and metering equipment.

Mercury-arc rectifiers used to be employed as converting machinery because of their much higher all-day efficiency, 100% overload capacity for few minutes, low maintenance cost, noiseless and reliable operation at all voltages and adaptability to remote control with simplicity of operations. Nowadays solid state devices are finding increasing use in these substations.

Since the rectifier used to be non-reversible, hence suitable arrangements were required to be made to receive the energy returned during regenerative braking. In cases where regenerated energy was considerable, inverters (grid – controlled rectifiers arranged to operate with reversed voltage) were employed. In other cases the energy used to be dissipated in a load resistor connected to the dc bus bars.

Transmission System For Traction Substations:

The substations lying along the railway track are fed by means of double transmission line running along the track. Double transmission line is employed to ensure continuity of supply. Normally, the current carried by each line is half of the total current but in case of fault on any line, the total current is carried by the healthy line.

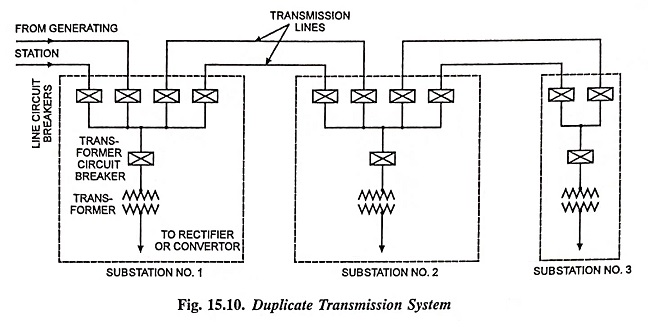

Line diagram of duplicate transmission system is shown in Fig. 15.10. In case of fault on any section, the faulty section is opened out by the line circuit breaker and the voltage drop in the other line of this section is doubled because it has to carry double the current. For each single unit substation there are four line circuit breakers and one transformer circuit breaker and since the cost of high voltage equipment increases very rapidly with higher voltages, it is clear that transmission lines operating at 220 or 132 kV must be tapped as seldom as possible.

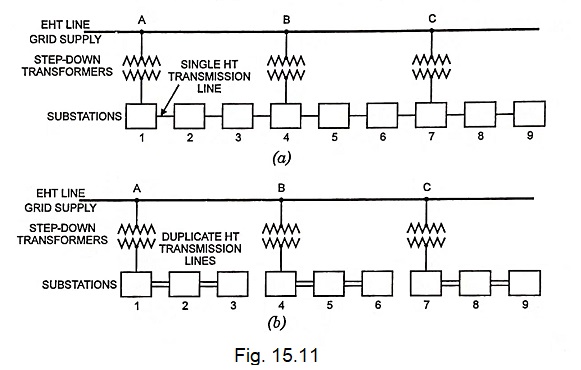

In case the ht supply is available from the grid, the substations are fed from the grid supply through step-down transformers. An arrangement for feeding the substations from the grid is shown in Fig. 15.11. The EHT supply is tapped at suitable points A, B and C, its voltage is stepped down by the transformers at substations at A, B and C. Now either a single ht transmission line may be taken to the substations from the transformer substations, as shown in Fig. 15.11(a) or duplicate transmission lines are provided between substations 1-2-3, 4-5-6, 7-8-9, as shown in Fig. 15.11(b) in order to avoid the risk of discontinuity of supply due to one of the faulty line.

Location of DC Substations:

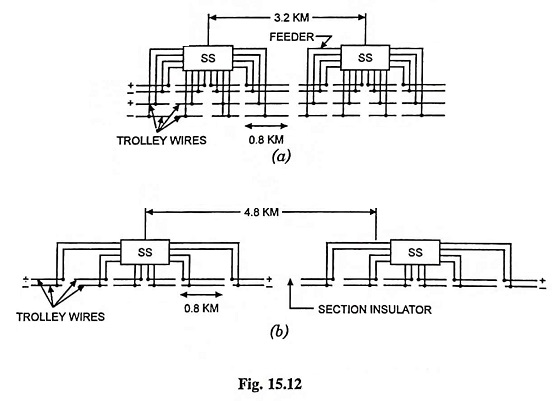

Since in case of trolley bus both the conductors are trolley wires, therefore, more voltage drop takes place in it and the spacing between substations is reduced in comparison to tramway substations for similar capacity. Hence the substations required are more in number and of lesser capacity. Spacing of substations is kept 4.8 km for single track and 3.2 km for double track (up and down). Each section of 0.8 km length is individually fed, as shown in Fig. 15.12.

For suburban railways the spacing of substations is usually determined from consideration of permissible variation of voltage at the trains and economy. The length of section depends upon the traffic density and substations spacing. The length of section may be from 3 to 5 km in general and distance between substations may be from 13 to 16 km. The sections can be isolated by sectional switches.

Feeding and Distributing Systems:

The electrical energy is supplied from a power station (or a substation) to a number of circuits at a constant voltage through distributor cables (known as distributors), which are fed at suitable points (known as feeding points) by other cables known as feeders. The feeders connect the feeding points to the station bus-bars and maintain these points at a definite voltage. The distributors supply the circuits at practically constant voltage. Thus the choice of cross section of distributor depends on permissible variation of voltage along the distributor while that for the feeder on the minimum annual operating expenses. In track electrification systems the trolley wires and track rails (or two sets of conductor rails) form the distributors.

The tramways and trolley bus systems in track electrification must conform to certain statutory regulations, chief among which are:

- The voltage at the trolley wire is not to exceed 550 volts and that at generating stations (or substations) 650 volts.

- The trolley wire shall be divided into sections not exceeding 1.6 km in length.

- The potential difference between any two points of the track rail return systems shall not exceed 7 volts.

- The potential difference between any point on the rail and earth should not exceed 4 volts.

Hence separate feeding systems are required for the trolley wire and the track rails in case of tramways in order to comply with these regulations.

In dc railways employing track rails as a return path, the voltage drop in the track rails is limited to such values that the working of telegraphic apparatus is not affected by earth currents. The positive portion of the distributing system need not to conform to statutory regulations with respect to voltage drop and sectionalizing at every 0.8 km.

The variation of voltage at the tramcars depends mainly upon the voltage drop in the trolley wire. The permissible variation in voltage depends upon service conditions.

The choice of length of the trolley wire between two feeding points depends upon the permissible voltage drop, current required in that section and particular of trolley wire.

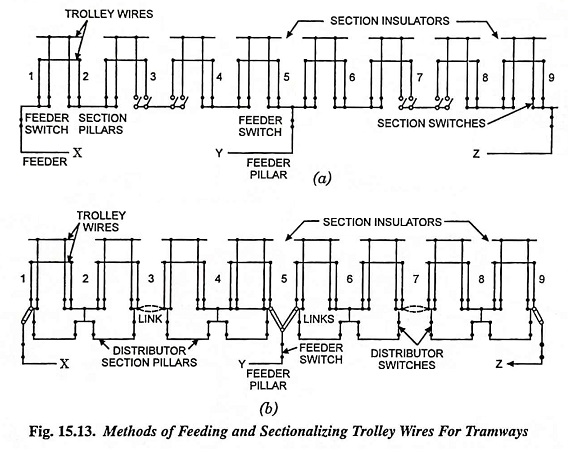

The method of feeding the trolley wire in case of tramways is largely influenced by traffic density and economical considerations. For heavy traffic a separate feeder supplied from substation is required for each section of 0.8 km length while with light traffic, several 0.8 km sections of the trolley wire are fed from a single feeder because of economical considerations. The two methods are shown diagrammatically in Fig. 15.13.

In one case [Fig. 15.13 (a)] the trolley wire is used as a distributor and each distribution section comprises two or more sections of trolley wires. In other case [Fig. 15.13 (b)] feeders of large x-section are run to a few points in the track electrification system from which current is distributed to the various sections of trolley wire by means of graded distributing cables. The second method is more economical and the variation of voltage in the adjacent sections is less.

The voltage along the track is kept within the limits of 7 volts above earth by employing negative booster. Sometimes more number of negative feeders of comparatively low resistance are used.

Advantages of Track Electrification DC Electrification System:

- DC trains consumes less electrical energy.

Disadvantages of Track Electrification DC Electrification System:

- This requires high cost of Substations

- Negative Booster is compulsorily needed for this dc system.