Transducers Interview Questions and Answers:

1. Explain in brief the term transducer.

Ans. Basically transducer is defined as a device which converts energy or information from one form to another. These are widely used in measurement work because all quantities that need to be measured, cannot be displayed as easily as others. A better measurement of a quantity can usually be made if it may be converted to another form which is more conveniently or accurately displayed. For example, the common mercury thermometer converts variations in temperature into variations in the length of a column of mercury. Since the variation in the length of the mercury column is rather simple to measure, the mercury thermometer becomes a convenient device for measuring temperature. On the other hand, the actual temperature variation is not as easy to display directly.

Thus the transducer is a device which provides a usable output in response to specific input measurand which may be physical or mechanical quantity, property or condition. The transducer may be mechanical, electrical, magnetic, optical, chemical, acoustic, thermal, nuclear, or a combination of any two or more of these.

2. What is difference between a sensor and a transducer?

Ans. Sensor is an input device which makes contact with the physical quantity under measurement, receives energy from the measured medium and produces an output depending in some way on the quantity under measurement, known as measunmd.

Sensors may have a non-electrical input and output such as an orifice plate, a spring, a manometer or may have electrical input and output such as a rectifier. In case the input device or the primary sensing element has a non-electrical input and output, then it is converted into electrical signal by means of a transducer. The transducer is defined as a device which, when actuated by one form of energy, is capable of converting it into another form of energy.

3. What are primary and secondary transducers?

Ans. When the input signal is directly sensed by the transducer and is converted into electrical form directly, such a transducer is called the primary transducer.

When the input signal is first sensed by some detector or sensor and its output being of some form other than input signal is given as input to a transducer for conversion into electrical form, such a transducer is called the secondary transducer.

4. What is an electrical transducer?

Ans. Basically an electrical transducer is a sensing device by which a physical, mechanical or optical quantity to be measured is transformed directly with a suitable mechanism, into an electrical signal, current, voltage or frequency.

5. What are the basic requirements of a transducer?

Ans. The basic requirements of a transducer are ruggedness, linearity, repeatability, high output signal quality, high reliability and stability, good dynamic response and absence of hysteresis and residual deformation.

6. Give classification of transducers.

Ans. Transducers may be classified in different ways such as on the basis of electrical principles involved, methods of application, methods of energy conversion used, nature of output signal like primary and secondary transducers, active and passive transducers, analog and digital transducers and transducers and inverse transducers.

7. Differentiate between active and passive transducers.

Ans. Self-generating type transducers i.e. the transducers, which develop their output in the form of electrical voltage or current without any auxiliary source, are called the active transducers. On the other hand the transducers in which electrical parameters (resistance, inductance or capacitance) changes with the change in input signal are called the passive transducers.

8. How does inverse transducer differ from a transducer ?

Ans. Transducer is defined as a device that converts a non-electrical signal into an electrical quantity while an inverse transducer is defined as a device that converts electrical quantity into a nonelectrical quantity.

9. What is strain gauge?

Ans. The strain gauge is basically a device used for measuring mechanical surface strain and is one of the most extensively used electrical transducers. Its working is based on the fact that when stress is applied on the metal conductor its resistance changes owing to change in length and cross-sectional area of the conductor. Resistance of the conductor under stress is also changed due to change in resistivity of the conductor. Strain gauges on the basis of operating technique used, may be mechanical, optical or electrical.

10. Why are strain gauges called the piezoresistive strain gauges ?

Ans. Resistance of a conductor under stress is also changed due to change in resistivity of the conductor, this property is called the piezoresistive effect and the strain gauges are called the piezoresistive.

11. Define gauge factor.

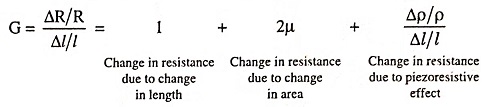

Ans. The gauge factor G indicates the strain sensitivity of the gauge in terms of the change in resistance per unit resistance per unit strain.

The gauge factor can be written as

Thus the strain Δl/l can be measured in terms of gauge factor, G and ΔR/R.

The strain Δl/l = ε and is usually measured in microstrain.

12. Give the advantages and limitations of foil strain gauges.

Ans. Strain gauges have the advantages of better sensitivity due to larger surface area and better gauge factor. But they have the limitations of low tensile strength and so heavy loads cannot be applied to it.

13. Explain why semiconductor strain gauges have high values for gauge factor.

Ans. Wire semiconductor devices produce large change in resistance for a small change in its strain, so its gauge factor is 50 times higher as compared to metal strain wire gauges.

14. Why is gauge factor G is about 2 for most of the metallic strain gauges?

Ans. Since for most of the metals, in elastic range, the Poisson’s ratio μ is almost constant and is equal to 0.6, the strain sensitivity or gauge factor G comes out to be 1.6 be G = (1 + 2 μ) + change in resistivity.

15. Why strain gauge is passive transducer?

Ans. The transducer that needs external power source for energy conversion is called the passive transducer so the strain gauge that needs an external power source is known as passive transducer.

16. Define sensitivity of strain gauge.

Ans. Sensitivity of a strain gauge is defined as the output produced per unit change in the input quantity being measured.

17. On what principle does a resistance thermometer operate?

Ans. A resistance thermometer operates on the principle of variation of resistance of a metal with temperature. Platinum or tungsten wire is wound on a former to give a resistance in the range of 10 Ω to 10 kΩ.

18. Give advantages and disadvantages of resistance thermometers.

Ans. Advantages : Resistance thermometer provide the most accurate method for temperature measurement. These have a simple installation and require only copper cables for long runs.

Disadvantages : These are large in size as compared to thermocouple and require energizing current.

19. What are thermistors?

Ans. Thermistors are also called the thermal resistors and the name is derived from thermally sensitive resistors, as the resistance of a thermistor varies as a function of temperature.

Thermistors are essentially semiconductor devices, that behave as resistors with high negative temperature coefficient (usually – 0.04 per °C) and are at least 10 times as sensitive as the platinum resistance thermometer.

20. What is utility of a thermistor?

Ans. The thermistors are rugged in construction, cheaper in cost and high sensitive devices. Although most applications of thermistors are in the field of measurement and control of temperature, they can be used in so many other applications such as temperature compensation, thermal conductivity measurement, measurement of gas composition, measurement of flow etc.

21. Why is thermistor well suited to precision temperature measurement, control and compensation ?

Ans. Because thermistors are rugged in construction, cheaper in cost and highly sensitive devices.

22. What is a thermocouple?

Ans. A thermocouple essentially consists of two dissimilar metal wires A and B, insulated from each other but welded or brazed together at their ends forming two junctions. Thermocouples are perhaps the most simple and most widely used devices for measurement of temperature.

23. What is LVDT?

Ans. LVDT is a differential transformer consisting of one primary winding P and two identical secondary windings S1 and S2 wound over a hollow bobbin of non-magnetic and insulating material. The secondary windings S1 and S2 are arranged concentrically and placed either side of the primary winding P.

24. Where is LVDT used?

Ans. LVDTs are suitable for use in applications where the displacements are too large for strain gauges to handle. For example, LVDTs can be employed for measurement of displacements that range from a fraction of a mm to a few cm. If LVDT is to be employed for measurement of mechanical displacement greater than 25 mm, an appropriate mechanical ratioing (gearing) must be used.

Since the LVDTs can also be connected to other transducers, whose outputs are mechanical displacements, these are often employed together with other transducers for measurement of force, weight, pressure etc.

25. Why is the frequency of excitation of primary winding of an LVDT kept very high as compared to the frequency of the signal being detected.

Ans. Frequency of excitation is kept high in order to avoid low-frequency noises.

26. How does the input voltage frequency affect the dynamic response of an LVDT?

Ans. The dynamic response is limited mechanically by the mass of the core and electrically by the frequency of applied voltage. The frequency of the carrier should be at least 10 times the highest frequency component to be measured.

27. What is capacitive transducer?

Ans. The variable capacitance transducer comprises of a capacitor, the capacitance of which is varied by the non-electrical quantity being measured.

28. What is a piezoelectric transducer?

Ans. A piezoelectric transducer can be thought of as a special capacitor which acquires a charge when a compressive force is applied to it. Its input is force and its output is charge.

We can also say that the transducers based on the piezoelectric effect are known as piezoelectric transducers.