Types of Magnetron:

The Various Types of Magnetron are

- 20-kW Conventional Metal Ceramic Magnetron

- 5-MW Long Anode Coaxial Magnetron

- Frequency agile or Dither tuned Magnetron

- Voltage Tunable Magnetron

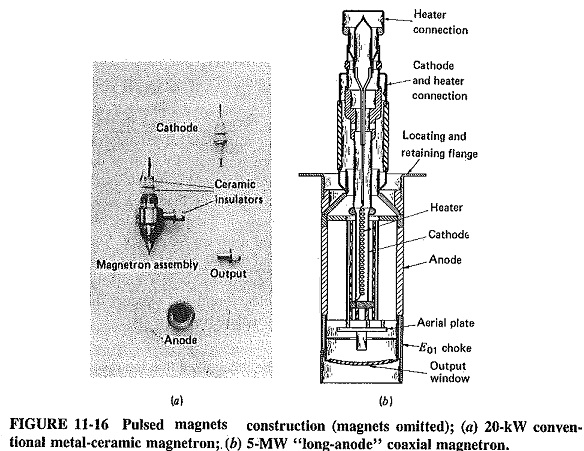

The Magnetron, perhaps more than any other microwave tube, lends itself to a variety of types, designs and arrangements. Magnetrons using hole-and-slot, vane and rising-sun cavities have already been discussed. Figure 11-16a shows the construction of another Vane-type magnetron, this time using an all-metal-ceramic structure. This type is in current use in marine radar, producing about 25 kW pulsed in the X band. The all-up weight of such a Types of Magnetron is typically 2 kg. A very high-power (5 MW pulsed at 3 GHz) magnetron is shown in Figure 11-16b. It features an anode that is about three times normal length and thus has the required volume and external area to allow high dissipation and therefore output power. The Types of Magnetron such as this may stand over 2 m high, and have a weight in excess of 60 kg without the magnet.

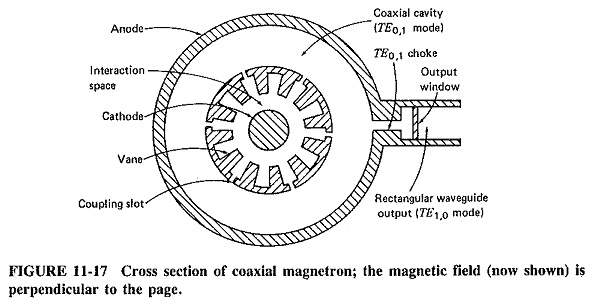

A most interesting feature of Figure 11-16b is that it shows a coaxial magnetron. The cross section of a coaxial magnetron structure, similar to the one of Figure 11-16b, is shown in Figure 11-17. It is seen that there is an integral coaxial cavity present in this Types of Magnetron. The tube is built so that the Q of this cavity is much higher than the Q’s of the various resonators, so that it is the coaxial cavity which determines the operating frequency. Oscillations in this cavity are in the coaxial TE0,1 mode, in which the electric field is circular, as is the magnetic field in Figure 10-13b (TM0,1 mode in circular waveguides). It is possible to attenuate the resonator modes without interfering with the coaxial mode, so that mode jumping is all but eliminated. Frequency pushing and pulling are both significantly reduced, while the enlarged anode area, as compared with a conventional magnetron, permits better dissipation of heat and consequently smaller size for a given output power. The MTBF of coaxial magnetrons is also considerably longer than that of conventional ones.

Frequency-agile (or dither-tuned) magnetrons are also available. They may be conventional or coaxial, the earlier ones having a piston which can be made to descend into the cavity, increasing or decreasing its volume and therefore its operating frequency. The piston is operated by a processor-controlled servomotor, permitting very large frequency changes to be made quickly. This is of advantage in radar, where it may be required to send a series of pulses each of which is at a different radio frequency. The benefits of doing this are improved resolution and more difficulty (for the enemy) in trying to jam the radar. Dither tuning by electronic methods has recently been produced, yielding very rapid frequency changes, during the transmission of one pulse, if required, with a range typically 1 percent of the center frequency. The methods used have included extra cathodes, electron injection and the placing of PIN diodes inside the cavity.

Voltage Tunable Magnetrons (VTMs) are also available for CW operation, though they are not very efficient. For this and other reasons they are not suited to pulsed radar work. These use low-Q cavities, cold cathodes (and hence back-heating) and an extra injection electrode to help bunching. The result is a magnetron whose operating frequency may be varied over an octave range by adjusting the anode voltage. Very fast sweep rates, and indeed frequency modulation, are possible.

Performance and Application of Magnetron:

The traditional applications of the Types of Magnetron have been for pulse work in radar and linear particle accelerators. The duty cycle (fraction of total time during which the magnetron is actually ON) is typically 0.1 percent. The powers required range from 10 kW to 5 MW, depending on the Application of Magnetron and the operating frequency. The maximum available powers range from 10 MW in the UHF band, through 2 MW in the X band, to 10 kW at 100 GHz. Current efficiencies are of the order of 50 percent; a significant size reduction is being achieved, especially for larger tubes, with the aid of two advancements. One is the development of modern permanent magnet materials, which has resulted in reduced electromagnet bulk. The other advance is in cathode materials. By the use of such substances as thoriated tungsten, much higher cathode temperatures (1800∘C compared with 1000∘C) are being achieved. This helps greatly in overcoming the limitation set by cathode heating from back bombardment.

VTMs are available for the frequency range from 200 MHz to X band, with CW powers up to 1000 W (10 W is typical). Efficiencies are higher, up to 75 percent. Such tubes are used in sweep oscillators, in telemetry and in missile Application of Magnetron.

Fixed-frequency CW magnetrons are also available; they are used extensively for industrial heating and microwave ovens. The operating frequencies are around 900 MHz and 2.5 GHz, although typical powers range from 300 W to 10 kW. Efficiencies are typically in excess of 70 percent.